Explore 7 Different Types of Interior Door Threshold?

I worry thresholds don’t fit right and cause drafts or tripping. That can ruin comfort fast.

I explain 7 types of interior door thresholds and how to pick, materials, and install one.

Let’s break this down so you read on with ease.

1. What Are Common Interior Door Threshold Types?

I feel unsure when I see many options and not know which fits best.

There are 7 common threshold types: saddle, t-bar, transition, ramp, reducer, flush, and decorative.

I list each one and explain how it works and when to use it. I use tables and headings to keep things clear.

Saddle Threshold

A saddle threshold sits under the door and bridges the gap.

It seals tightly and protects from drafts. It works well where you have same-height floors on both sides.

Details

| Feature | Description |

|---|---|

| Use case | Same level floors, want tight seal |

| Advantage | Good draft control, simple |

| Limitation | Not good if floor height differs |

Saddle thresholds are simple and easy to seal well. I often use them for doors between rooms at same floor level. They help block air and dust.

t-bar Threshold

I use a t-bar when I need to transition between floors of different heights but keep clearance for the door.

Details

| Feature | Description |

|---|---|

| Use case | Different floor heights, need door clearance |

| Advantage | Smooth rise/dip, clear door swing |

| Limitation | May need ramp or edge treatment for safety |

The T shape lifts one side up, letting the door swing without hitting. I like them where hardwood meets tile.

Transition Threshold

Transition thresholds tie two floor types with small height differences and good finish.

Details

| Feature | Description |

|---|---|

| Use case | Slight floor height difference, finish harmony |

| Advantage | Looks clean, small bump |

| Limitation | Doesn’t hide large height gaps |

They work where wood meets vinyl or carpet and difference is slight.

Ramp Threshold

Ramp thresholds ease large height differences with a slight slope.

Details

| Feature | Description |

|---|---|

| Use case | Large difference in floor heights |

| Advantage | Smooth slope, safe |

| Limitation | Needs space for ramp shape |

I often install these at exits to basement where floors drop or rise.

Reducer Threshold

Reducers make a smooth slope from higher floor to lower.

Details

| Feature | Description |

|---|---|

| Use case | High to low floor with gradual slope |

| Advantage | Soft visual and physical transition |

| Limitation | Takes more length |

They work well where hardwood meets lower vinyl or concrete.

Flush Threshold

Flush thresholds sit level with the floor on both sides. No bump at all.

Details

| Feature | Description |

|---|---|

| Use case | Rooms with same low height flooring |

| Advantage | Seamless look, safe |

| Limitation | Hard to seal tight against air or dust |

I choose flush for modern, flat transitions in same-floor areas.

Decorative Threshold

These focus on design. They may shape or pattern the threshold area.

Details

| Feature | Description |

|---|---|

| Use case | Style, visible thresholds |

| Advantage | Enhances design |

| Limitation | May cost more, still need correct fit |

I pick decorative when door area is focal, and I still match function.

Correct claim:

There are 7 common interior door threshold types.True

I listed saddle, t-bar, transition, ramp, reducer, flush, and decorative thresholds.

Incorrect claim:

Only one type of threshold is suitable for different floor heights.False

Multiple types—for example t-bar, ramp, reducer—are designed for managing floor height differences.

2. How Do I Choose a Threshold for Hardwood Floors?

I worry that hardwood can be damaged by wrong height or material mismatch.

I choose thresholds for hardwood by matching height, material, and seal while keeping good looks.

I go deeper so you know why and how to pick.

Factors to Consider

-

Floor height

I measure hardwood thickness. The threshold should sit flush or gently slope. If height matches tile or other side, I use saddle or flush. If heights differ, I use t-bar, reducer, or ramp. -

Material match

I use hardwood, metal, or engineered wood thresholds. I pick a similar tone to hardwood, or neutral finish if mixing materials. -

Seal-tightness

For exterior-facing doors, or rooms needing tight seal, I pick saddle or flush with seal strip. -

Appearance

I want the threshold to blend or contrast nicely. Decorative or flush suits design rooms. I avoid bulky thresholds in sleek interiors. -

Durability

Hardwood gets worn. I pick hardwood threshold or metal if area is high-traffic. Metal holds up better to wear but may scratch; I test finish.

Example Table

| Scenario | Threshold Type | Why it works |

|---|---|---|

| Hardwood to tile, same height | Flush or saddle | Clean look, tight fit |

| Hardwood to concrete, lower | Reducer or ramp | Gently slopes, safe transition |

| Hardwood to carpet, small gap | Transition threshold | Matches slight height difference, tidy finish |

Correct claim:

Reducer thresholds help transition from hardwood to lower floors.True

Reducers are designed to slope from a higher floor like hardwood to a lower floor safely.

Incorrect claim:

Flush thresholds are ideal when there is a big height difference.False

Flush thresholds work only when floor heights are equal; they do not accommodate height differences.

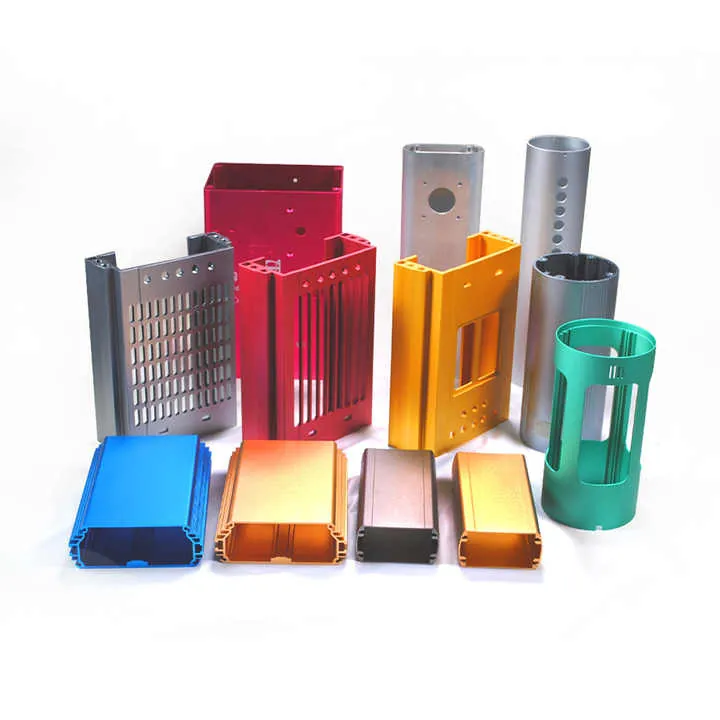

3. What Materials Are Used for Door Thresholds?

I often wonder if wood, metal, or vinyl is best for my use.

Thresholds use materials like hardwood, aluminum, bronze, PVC, and composite to fit needs.

I examine each material’s pros and cons so you pick smart.

Hardwood

I like hardwood thresholds for visual match and warmth. They fit well with hardwood floors.

- Pros: Matches wood floor, warm finish, easy to work.

- Cons: Prone to wear, may need seal; not best for moisture.

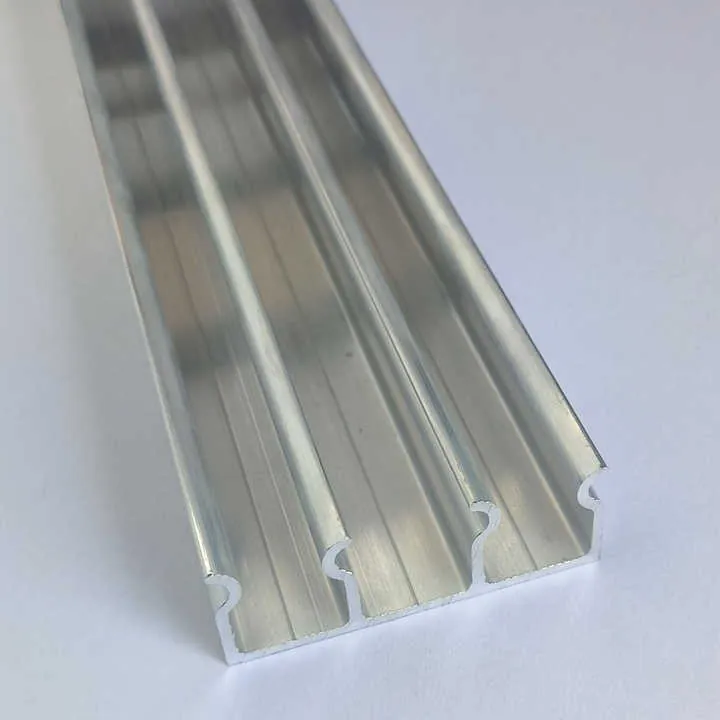

Aluminum

Aluminum is sleek and durable. Works well in high-traffic or moisture zones.

- Pros: Long lasting, low maintenance, good with drops.

- Cons: Cold, may scratch, may not match wood tone.

Bronze or Brass

These give classic look and patina nicely.

- Pros: Elegant, durable.

- Cons: Expensive, may patina in unwanted areas.

PVC or Vinyl

These are cheap and resist water.

- Pros: Moisture-resistant, low-cost.

- Cons: Looks cheap, may fade.

Composite or Engineered Wood

These combine durability and wood-look.

- Pros: Stable, decent look, moisture-resistant.

- Cons: Cost varies, may not match real wood grain.

I often use this comparison:

| Material | Best Use | Drawback |

|---|---|---|

| Hardwood | Match hardwood floors | Wear, moisture risk |

| Aluminum | High traffic, basements, wet areas | Cold feel, may scratch |

| Bronze/Brass | Decor, classic interiors | High cost |

| PVC/Vinyl | Cheap, utility, bathrooms | Less attractive |

| Composite | Durable, matched look, busy areas | Price and visual match vary |

Correct claim:

Aluminum thresholds work well in moisture-prone areas.True

Aluminum resists moisture and wears well, so it's suitable for damp zones.

Incorrect claim:

PVC thresholds are the most attractive for high-end designs.False

PVC is low cost and moisture-resistant, but often lacks the look of higher-end materials.

4. How Do You Install a Door Threshold Properly?

I worry that wrong install makes drafts or shapes bad trip hazards.

Install a threshold by measuring, cutting, fitting, sealing, and securing it level and tight.

Here is how I do it step by step with detail and clarity.

Steps to Install

1. Measure and Select Type

I measure the door width and floor heights. I pick type that fits the difference and suits material and seal need.

2. Cut to Fit

I cut threshold to door width minus about 1/8 inch. That gives room for expansion.

3. Dry-fit Check

I place threshold in spot to ensure it meets both floor sides and clears the door swing.

4. Prep Surface

I clean floor. I may plane floor edges so threshold sits flat and snug.

5. Apply Seal or Adhesive

For weather or tight seal, I apply silicone or threshold seal tape under threshold edges.

6. Attach Threshold

- For wood or composite, I pre-drill and screw it down.

- For metal, I may use special fasteners or screws with anchors.

- I make sure screws sit flush or slightly countersunk.

7. Seal Edges

I run bead of sealant (like caulk) at edges where threshold meets floor and door jamb to stop air or water.

8. Final Adjust

I test door swing and walk over threshold to check stability and smoothness.

Example Table

| Step | Action | Why It Matters |

|---|---|---|

| Measure | Fit width and height | Ensures barrier and clearance |

| Dry-fit | Check fit and swing | Avoids cutting error |

| Seal | Stop drafts and moisture | Keeps energy in and water out |

| Screw or Fasten | Secure threshold in place | Avoids movement and tripping risk |

Correct claim:

You should dry-fit the threshold and check door swing before permanent fixing.True

No explanation available.

Incorrect claim:

You can skip sealing edges if threshold fits tightly.False

Even tight fits can leak air or water; sealing improves performance.

Conclusion

I explored seven threshold types, choosing one for hardwood floors, materials, and installation steps. With clear steps, I can pick and fit a threshold that looks good, works well, and lasts.