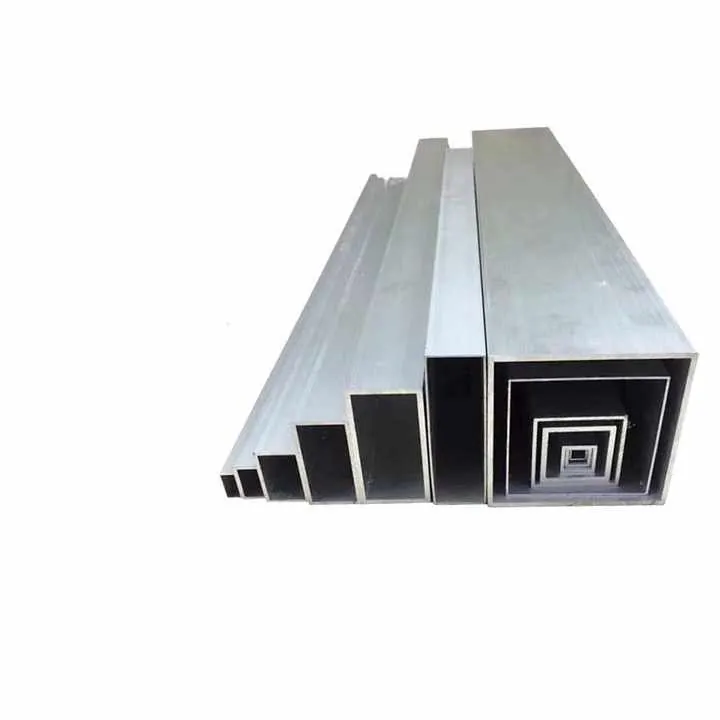

Alumiiniumi ekstrusiooni tolerantsus keerulise geomeetria puhul?

Komplekssed alumiiniumprofiilid ebaõnnestuvad oodatust sagedamini. Osad ei sobi. Kokkupanekud peatuvad. Kulud tõusevad kiiresti. Paljud ostjad alahindavad tolerantsi piire, kui geomeetria muutub keeruliseks.

Alumiiniumi ekstrusiooni tolerantsus keerulise geomeetria puhul sõltub profiili kujust, seina paksuse tasakaalust, sulamist, stantsi konstruktsioonist ja protsessi juhtimisest. Keerukate vormide puhul on saavutatav tolerants alati väiksem kui lihtsate profiilide puhul, kui ei kasutata sekundaarset mehaanilist töötlemist.

See teema on oluline, sest keerulised profiilid on nüüdseks levinud ehituses, päikeseenergias, transpordis ja automatiseerimises. Tolerantspiiride varajane mõistmine väldib ümberprojekteerimist, viivitusi ja varjatud kulusid.

Millised tolerantsid kehtivad keeruliste ekstrusioonivormide puhul?

Keerukad profiilid näevad joonistel ideaalselt välja. Tootmises käituvad nad teisiti. Teravad nurgad, sügavad õõnsused ja ebatasased seinad panevad ekstrusiooni oma piiridesse. Paljud ostjad eeldavad, et tolerantsid jäävad samaks. See ei ole nii.

Keerukate ekstrusioonivormide puhul on mõõtmete tolerantsid suuremad kui lihtsate profiilide puhul, sest metalli voolamine muutub ekstrusiooni käigus ebaühtlaseks, eriti õhukeste seinte ja õõnesprofiilide puhul.

Miks keerulised kujud käituvad erinevalt

Alumiiniumi ekstrusioon on kuumvormimine. Alumiinium voolab läbi survevälja. Lihtsate vormide puhul püsib voolamine tasakaalus. Keerukate vormide puhul on voolukiirused eri sektsioonides erinevad.

Tolerantsi varieerumist põhjustavad mitmed tegurid:

- Õhukesed lõigud jahtuvad kiiremini kui paksud

- Pikad konsoolsed omadused painduvad väljumise ajal

- Õõnesprofiilid deformeeruvad karastamise ajal

- Asümmeetriline disain tõmbab materjali ebaühtlaselt

Iga küsimus suurendab mõõtmete kõrvalekaldumist.

Tüüpilised lubatud hälbed

Enamiku tööstuslike ekstrusioonide puhul järgivad tolerantsid tööstusstandardeid, nagu EN või ASTM. Keeruline geomeetria surub tulemusi siiski alati tolerantsi ülemise piiri suunas.

| Profiili tüüp | Tüüpiline laiuse tolerants | Tüüpiline sirgus |

|---|---|---|

| Lihtne tahke | +/- 0,15 mm | 1/1000 pikkus |

| Lihtne õõnes | +/- 0,20 mm | 1,5/1000 pikkus |

| Kompleksne õõnes | +/- 0,30 mm kuni 0,50 mm | 2/1000 pikkus |

Need on realistlikud tootmisväärtused, mitte laboritulemused.

Kriitilised omadused vs. üldine suurus

Kõik mõõtmed ei käitu ühtemoodi. Välislaius võib jääda stabiilseks. Sisemised pilud või sooned liiguvad rohkem.

Olulised punktid, mida jälgida:

- Aukude laius varieerub rohkem kui välislaius

- Nurga raadiused suurenevad ekstrusiooni ajal

- Sügavad kanalid sulguvad veidi pärast kustutamist

See on oluline, kui profiilid sobituvad kinnitusdetailide või muude detailidega.

Projekteerimisotsused, mis aitavad

Tolerantsuse kontroll algab projekteerimise etapis. Lihtsad muudatused vähendavad riski:

- Võimaluse korral tasakaalustage seina paksus

- Vältida väga sügavaid kitsaid õõnsusi

- Säilitada sümmeetria ümber keskjoone

- Suurendage veidi nurgaraadiusi

Need sammud ei maksa sageli midagi, kuid säästavad hiljem nädalaid.

Reaalsuse kontroll ostjatele

Joonistel on sageli ette nähtud kitsad tolerantsid kõigi omaduste osas. See tekitab konflikti. Ekstrusioon võib täita funktsionaalseid tolerantse, mitte kõikjal ideaalseid.

Mõistmine, kus sallivus on tõeliselt oluline, on võti.

Komplekssed alumiiniumist pressprofiilid nõuavad tavaliselt suuremaid tolerantse kui lihtsad vormid, mis on tingitud metalli ebaühtlasest voolamisest.Tõsi

Keerukad vormid tekitavad tasakaalustamata voolu ja jahutuse, mis loomulikult suurendab mõõtmete varieeruvust.

Keerukate ekstrusiooniprofiilide puhul on võimalik saavutada samad tihedad tolerantsid kui lihtsate tahkete detailide puhul, ilma et oleks vaja muuta protsessi.Vale

Keeruline geomeetria vähendab tolerantsi, kui ei ole lisatud mehaanilist töötlemist või spetsiaalset kontrolli.

Kuidas mõjutab profiili keerukus tolerantsuse kontrolli?

Keerukus ei tähenda ainult kuju. See tähendab ka seda, kuidas alumiinium käitub kuumuse, rõhu ja kiiruse all. Iga lisatud funktsioon suurendab riski.

Profiili keerukus vähendab tolerantsi kontrolli, sest see tekitab ebaühtlase metallivoolu, suurema survetugevuse ja suurema moonutuse jahutamise ja sirgendamise ajal.

Metallivoolu tasakaalustamatus

Inside the die, aluminum takes the easiest path. Thin areas fill faster. Thick areas lag behind.

See põhjustab:

- Bowing in long profiles

- Twisting in asymmetrical shapes

- Local size variation along length

Even with perfect dies, physics still applies.

Die deflection and wear

Complex dies have thin tongues and bridges. Under pressure, these parts move slightly.

Over time:

- Die openings widen

- Critical dimensions drift

- Repeatability drops

This is why early samples often look better than later batches if the die is not maintained.

Cooling and quenching effects

After extrusion, profiles are cooled. Cooling is rarely uniform in complex shapes.

Results include:

- Warping of hollow sections

- Shrinkage differences across walls

- Loss of flatness

Thicker areas retain heat longer. Thin fins cool fast and pull inward.

Straightening limitations

Stretch straightening corrects lengthwise distortion. It cannot fully correct cross-section distortion.

Key limits:

- Twisting cannot be fully removed

- Thin fins may crack if overstretched

- Internal cavities remain distorted

This sets a hard boundary on tolerance control.

Complexity scoring concept

Many engineers use an informal complexity score during quoting.

| Complexity Level | Example Features | Tolerance Risk |

|---|---|---|

| Madal | Solid bars, flat shapes | Madal |

| Keskmine | Simple hollows, T-slots | Keskmine |

| Kõrge | Multi-cavity, thin fins | Kõrge |

Higher complexity always means higher cost or looser tolerance.

Cost vs tolerance trade-off

To control tolerance in complex profiles, manufacturers may:

- Reduce extrusion speed

- Use special die materials

- Add intermediate aging steps

- Increase inspection frequency

Each step adds cost. Buyers must decide what matters most.

Practical takeaway

Complexity multiplies tolerance risk. This is not a quality failure. It is process reality.

Clear communication early prevents disputes later.

Higher profile complexity increases the difficulty of controlling extrusion tolerances.Tõsi

Complex shapes cause uneven flow, die deflection, and cooling distortion, which reduce tolerance control.

Extrusion speed has no impact on tolerance control in complex aluminum profiles.Vale

Slower extrusion speeds are often required to improve tolerance stability in complex shapes.

Can machining compensate for extrusion tolerances?

Extrusion alone cannot solve every tolerance problem. Machining exists for a reason. But machining is not free, and it has limits.

Machining can compensate for extrusion tolerances on critical features, but it increases cost and should be applied only where function demands precision.

What machining does well

Machining removes material in a controlled way. It excels at:

- Slot width control

- Hole position accuracy

- Flatness and parallelism

- Liidese pinnad

These features often matter most in assembly.

What machining cannot fix

Machining does not correct everything:

- Overall twist along length

- Severe bowing

- Internal cavity distortion without access

If the base extrusion is too far off, machining becomes inefficient.

Hybrid tolerance strategy

The best approach often combines extrusion and machining.

Steps usually look like this:

- Extrude within realistic tolerance

- Identify functional features

- Machine only critical zones

- Leave non-critical areas as-extruded

This keeps cost under control.

Cost impact overview

| Funktsiooni tüüp | Ainult ekstrusioon | With Machining |

|---|---|---|

| External width | Madalad kulud | Keskmine |

| Internal slot | Keskmine | Kõrge täpsus |

| Precision hole | Not possible | Nõutav |

| Flat mounting face | Piiratud | Suurepärane |

Machining shifts cost from tooling to labor and cycle time.

Design for machining from start

Problems arise when machining is added late. Smart designs allow easy fixturing.

Kasulikud disainivalikud:

- Add flat reference faces

- Avoid deep unreachable pockets

- Group machined features together

- Keep machining direction simple

These reduce cycle time and scrap.

Tolerance stack control

Machining also helps manage tolerance stacks in assemblies. Instead of tightening every extrusion tolerance, precision is added only where parts meet.

This approach improves yield.

Buyer mindset shift

Extrusion is for shape. Machining is for precision. Expecting extrusion to behave like machining leads to frustration.

Using both correctly delivers stable results.

Machining is effective for improving accuracy on critical features of aluminum extrusions.Tõsi

Machining allows precise control of features such as slots, holes, and flat surfaces.

Machining can fully correct severe twisting and bowing caused during extrusion.Vale

Machining cannot economically fix large-scale distortion along the profile length.

Which inspection techniques measure complex geometry accuracy?

Measuring complex geometry is harder than making it. Many disputes come from measurement methods, not actual defects.

Accurate inspection of complex extrusion geometry requires a mix of coordinate measurement, optical scanning, and functional gauges rather than simple calipers alone.

Limits of basic tools

Calipers and micrometers work for simple dimensions. They fail with:

- Sisemised õõnsused

- Irregular profiles

- Twisted sections

Relying only on basic tools hides real issues.

Koordinaatmõõtmismasinad

CMMs are common for complex profiles.

Nad pakuvad:

- High point accuracy

- Repeatable results

- Data export for analysis

However, CMMs require skilled operators and stable fixturing.

Optical and laser scanning

For highly complex shapes, scanning is useful.

Eelised hõlmavad järgmist:

- Full profile capture

- Fast comparison to CAD

- Visual deviation maps

Limits include surface reflectivity and resolution limits on sharp edges.

Functional gauges

Sometimes, the best inspection is functional.

Näited:

- Go/no-go gauges

- Assembly fit tests

- Sliding tests

If the part works in assembly, it often passes function even if some dimensions drift.

Inspection method comparison

| Meetod | Täpsus | Kiirus | Parim kasutusviis |

|---|---|---|---|

| Kalibreid | Keskmine | Kiire | Simple features |

| CMM | Kõrge | Keskmine | Critical dimensions |

| Laser scan | Keskmine kuni kõrge | Kiire | Complex geometry |

| Functional gauge | Function-based | Kiire | Assembly fit |

No single method solves all needs.

Inspection frequency matters

Complex profiles need more frequent checks, especially early in production.

Best practice includes:

- First article inspection

- Käimasolevad kontrollid

- Final batch sampling

Skipping early checks increases scrap risk later.

Communication of results

Inspection reports must match drawing intent. Over-measuring irrelevant features creates confusion.

Clear definition of critical dimensions keeps focus on what matters.

Complex aluminum extrusion geometry often requires advanced inspection methods beyond basic calipers.Tõsi

CMMs, scanning, and functional gauges are needed to assess complex features accurately.

Functional testing is unreliable and should never be used for extrusion inspection.Vale

Functional gauges are valuable when the real requirement is assembly fit, not isolated dimensions.

Kokkuvõte

Complex aluminum extrusion geometry always challenges tolerance control. Better results come from realistic design, selective machining, and proper inspection. Understanding process limits early reduces cost, delays, and quality disputes.