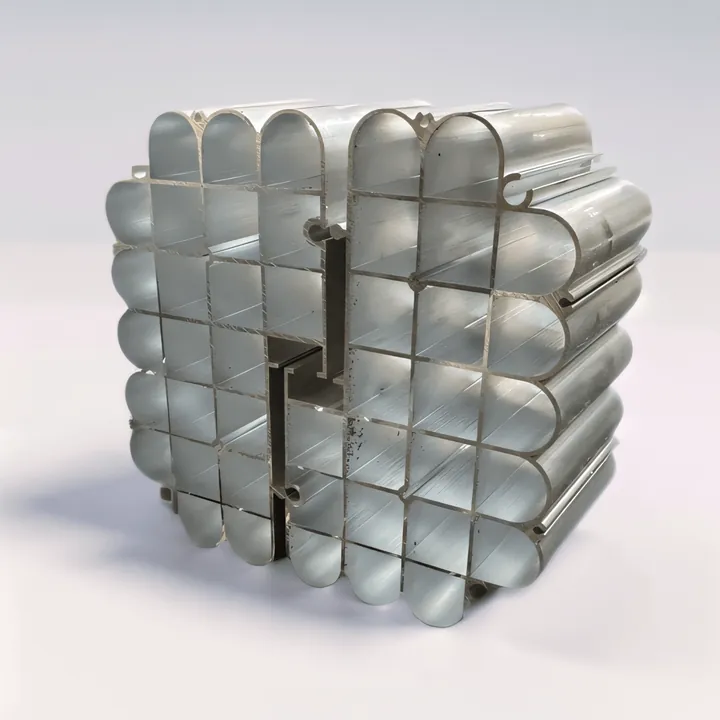

Alumiiniumi ekstrusioonitolerants pärast töötlemist?

Machined aluminum extrusions often fail fit checks because buyers assume extrusion tolerance equals final tolerance. This gap causes scrap, delays, and cost stress.

After machining, aluminum extrusion tolerance depends on the extrusion class, machining method, part size, and inspection control. With the right process, tight and stable tolerances are achievable.

Many buyers stop reading at the extrusion standard. That is risky. The real answer starts after the cutter touches the profile.

What tolerance levels are typical post-machining?

Machining aluminum extrusions reduces dimensional variation, but it does not remove all limits. The final tolerance depends on how much material is removed, where it is removed, and how stable the part stays during cutting.

For most CNC machined aluminum extrusions, typical linear tolerances range from +/-0.05 mm to +/-0.10 mm. Tighter tolerance is possible on critical features with controlled setups.

Why extrusion tolerance still matters

Extrusion is the starting point. Even after machining, the original shape affects the result. If the extrusion has twist, bow, or wall variation, machining must correct it. Correction needs extra cuts and stable fixturing.

Common extrusion standards like ISO and EN allow wider tolerance than machining needs. This means machining often removes more material just to clean up the surface. That increases time and cost.

Typical tolerance ranges after machining

Below is a simple view based on real production cases.

| Funktsiooni tüüp | Tüüpiline tolerants |

|---|---|

| Overall length | +/-0.10 mm |

| Milled slot width | +/-0.05 mm |

| Aukude asend | +/-0.05 mm |

| Flatness after face milling | 0.05 to 0.10 mm |

These values assume good fixturing and normal part size. Very long profiles or thin walls may need looser limits.

Material and stress release

Aluminum releases internal stress when cut. This can cause slight movement after rough machining. For long or thin parts, this movement affects final size.

To control this, rough machining is often done first. The part rests. Then final machining is applied. This two step method improves stability.

Cost and tolerance balance

Tighter tolerance means more time, more checks, and higher cost. Many designs ask for tight limits on all features. That is not needed.

A better approach is to tighten tolerance only where function needs it. Other areas can stay wider.

Typical post machining tolerance for CNC machined aluminum extrusions is usually within plus or minus 0.05 to 0.10 mm.Tõsi

This range matches common CNC capability when extrusion quality and fixturing are controlled.

Machining always removes the influence of extrusion straightness and twist.Vale

Extrusion defects still affect machining and may require extra material removal or looser tolerance.

How does machining method affect final tolerance?

Not all machining methods control tolerance the same way. The tool path, cutting force, and clamping method all change the final size.

CNC milling provides the most stable and repeatable tolerance, while drilling, tapping, and manual operations show wider variation.

CNC milling vs drilling

CNC milling uses controlled tool paths and constant feed. This allows close control of size and position. Drilling depends more on tool wear and chip flow.

Holes drilled in thin walls may shift slightly. Milling a pocket or slot usually holds better size.

Manual machining limits

Manual milling or drilling can work for simple parts. But repeatability is lower. Operator skill matters a lot.

For B2B volume orders, manual methods are risky when tolerance is tight.

Fixturing and clamping effect

How the part is held is often more important than the machine itself. Aluminum extrusions are long and flexible.

Poor clamping causes bending during cutting. When released, the part springs back. The measured size changes.

Good fixtures support the full length and avoid point pressure.

Tool wear and heat

Aluminum cuts fast but builds heat. Heat causes expansion. If the tool is hot, the cut size shifts.

CNC shops manage this with sharp tools, coolant, and stable cycle times.

Comparison of machining methods

| Machining method | Tolerance capability |

|---|---|

| CNC freesimine | Kõrge |

| CNC drilling | Keskmine |

| Tapping | Keskmine kuni madal |

| Manual machining | Madal |

Batch size and consistency

Large batch orders benefit from CNC because the process stays stable. Small batches may show more variation if setups change.

For export projects with repeat orders, method choice affects long term consistency more than one time accuracy.

CNC milling generally achieves tighter and more repeatable tolerance than manual machining.Tõsi

CNC control, fixed programs, and stable fixturing reduce variation.

Drilling holes always holds the same tolerance as CNC milling slots.Vale

Drilling is more sensitive to tool wear and wall thickness, so variation is higher.

Can fine machining meet tight tolerance requirements?

Many buyers ask if aluminum extrusions can meet very tight tolerance after machining. The short answer is yes, but only under clear conditions.

Fine machining can meet tight tolerances such as +/-0.02 mm on selected features when design, process, and inspection are aligned.

What fine machining really means

Fine machining is not just slower cutting. It is a full process.

It includes stress relief, controlled roughing, stable finishing, and careful inspection.

Without these steps, asking for tight tolerance leads to scrap.

Design plays a key role

Tolerance should match function. Many drawings copy limits from steel parts. Aluminum behaves differently.

Thin walls move more. Long profiles bend easier. Tight tolerance across the full length is risky.

Designers should isolate critical features and relax others.

Process control steps

Fine machining usually follows these steps:

- Rough machining with extra allowance

- Rest time to release stress

- Finish machining with light cuts

- Temperature control in workshop

Skipping any step reduces accuracy.

Practical tight tolerance range

In real projects, these limits are common:

| Funktsioon | Achievable tolerance |

|---|---|

| Critical hole diameter | +/-0.02 mm |

| Mating surface flatness | 0.02 to 0.05 mm |

| Non critical length | +/-0.10 mm |

These values depend on part size and shape.

Risk and cost awareness

Tight tolerance increases cycle time and inspection cost. Yield drops if extrusion quality is uneven.

Buyers should request capability confirmation before mass order.

Fine machining works best when extrusion supplier and machine shop work as one team.

Fine machining can achieve plus or minus 0.02 mm on selected aluminum extrusion features.Tõsi

With controlled process and proper design, this level is achievable.

All features on an aluminum extrusion can hold plus or minus 0.02 mm without added cost.Vale

Applying tight tolerance everywhere increases cost and scrap risk.

Which inspection methods verify post-machining dimensions?

Even perfect machining means nothing without proof. Inspection verifies that the part meets the drawing.

Post machining dimensions are verified using calipers, micrometers, CMM, and functional gauges depending on tolerance level.

Basic measuring tools

Calipers and micrometers handle most checks. They are fast and flexible.

However, operator technique affects results. Pressure and angle matter.

For export projects, calibration records are important.

CMM inspection

Coordinate Measuring Machines provide high accuracy and repeatability. They measure complex geometry and position.

CMM is ideal for tight tolerance and complex profiles. It also creates inspection reports for customer records.

The downside is time and cost. Not every feature needs CMM.

Go and no go gauges

For high volume parts, gauges are efficient. They check function, not size.

If the part fits, it passes. This reduces inspection time.

Gauges work best when design allows clear functional limits.

Inspection method selection

| Kontrollimeetod | Parim kasutusjuhtum |

|---|---|

| Caliper | General size check |

| Mikromeeter | Tight diameter control |

| CMM | Complex and tight tolerance |

| Functional gauge | High volume repeat checks |

Inspection timing

Inspection should happen after final machining and before surface treatment. Anodizing and coating add thickness.

If coating is applied, tolerance must include coating thickness.

Clear agreement on inspection stage avoids disputes.

Documentation and trust

Inspection reports build trust in B2B supply. They show control, not just results.

For long term buyers, stable inspection data matters more than one perfect batch.