Alumiinium ekstrusiooni keskkonna vastupidavuse hinnang?

Keskkonnakahjustused ilmnevad sageli aeglaselt, kuid muutuvad siis järsku kalliks. Alumiiniumprofiilid näevad esialgu stabiilsed välja, kuid kliima, saaste ja niiskus hoiavad iga päev tööd. Paljud ostjad mõistavad vastupidavusprobleeme alles pärast paigaldamist.

Alumiiniumprofiilide keskkonnaalase vastupidavuse hinnang sõltub katsemeetoditest, kliima kokkupuutest, pinnakaitsest ja vastupidavusnormide järgimisest. Alumiinium kestab kaua, kuid ainult siis, kui tehakse õigeid valikuid.

Kui alumiiniumprofiilid väljuvad tehasest, muutub keskkond tõeliseks katsumuseks. Vastupidavuse hinnangute mõistmine aitab vältida varjatud pikaajalist riski.

Milliste vastupidavuskatsetega hinnatakse keskkonnaga kokkupuudet?

Keskkonnakindlus ei põhine arvamistel. Seda mõõdetakse standardiseeritud katsete abil, mis simuleerivad pikaajalist kokkupuudet.

Vastupidavuskatsetega hinnatakse, kuidas alumiiniumprofiilid peavad aja jooksul vastu korrosioonile, niiskusele, UV-valgusele ja temperatuurimuutustele.

Korrosioonikindluskatsed

Korrosioon on enamikus keskkondades alumiiniumi peamine oht. Katsed seavad proovid agressiivsetesse tingimustesse.

Tavalised korrosioonikatsed hõlmavad järgmist:

- Soolaprits-katse

- Äädikhappe soolade pihustamine

- Tsüklilised korrosioonikatsed

Katete ja pinnatöötluse võrdlemiseks kasutatakse laialdaselt soolapritskatsetusi. See ei ennusta täpset kasutusiga, kuid näitab suhtelist vastupidavust.

Niiskuse ja niiskuse testimine

Kõrge õhuniiskus kiirendab korrosiooni ja katte purunemist.

Niiskuskatsed kontrollivad:

- Blistering

- Koorimine

- Haardumise kadumine

Proovid viibivad kuumades, niisketes kambrites sadu või tuhandeid tunde.

UV- ja ilmastikukatsed

Välisalumiinium seisab iga päev silmitsi päikesevalgusega. UV-kiirgus lagundab katteid.

Ilmastikukatsed simuleerivad:

- UV-kiirguse kokkupuude

- Vihmatsüklid

- Soojuse varieerumine

Need katsed on kriitilise tähtsusega arhitektuuri- ja tööstuslikele välisprofiilidele.

Temperatuuritsüklikatsed

Temperatuurimuutus põhjustab paisumist ja kokkutõmbumist.

Termotsüklikatsed näitavad:

- Cracking

- Kattekihi eraldamine

- Ühine stress

See on oluline piirkondades, kus on kuumad päevad ja külmad ööd.

Ülevaade üldiste vastupidavuskatsete kohta

| Katse tüüp | Eesmärk |

|---|---|

| Soolaprits | Korrosioonikindlus |

| Niiskuskatse | Niiskuse vastupidavus |

| UV-kiirguse mõju | Värvi ja katte stabiilsus |

| Termiline tsüklilisus | Stressitaluvus |

Alumiiniumprofiilide keskkonnaalast vastupidavust hinnatakse standardiseeritud laborikatsete abil.Tõsi

Katsed simuleerivad korrosiooni, niiskust, UV-kiirgust ja temperatuurimuutusi.

Ainuüksi visuaalne kontroll on piisav, et hinnata alumiiniumi keskkonnakindlust.Vale

Vastupidavuse hinnangud põhinevad kontrollitud testidel, mitte ainult väljanägemisel.

Kuidas mõjutavad kliimatingimused ekstrusiooni kasutusiga?

Alumiinium toimib erinevalt sõltuvalt sellest, kus seda kasutatakse. Kliima on üks tugevamaid tegureid, mis mõjutab eluea pikkust.

Kliimatingimused, nagu niiskus, temperatuur, saaste ja soolaga kokkupuutumine, mõjutavad otseselt alumiiniumprofiilide kestvust.

Mere- ja rannikukeskkond

Rannikualad sisaldavad õhus soola. Sool kiirendab korrosiooni.

Nendes piirkondades:

- Paljas alumiinium korrodeerub kiiremini

- Kaitsekatted on olulised

- Regulaarne puhastamine parandab kasutusiga

Ilma kaitseta võib varakult ilmneda pinna lõhestumine.

Tööstus- ja linnakeskkond

Linnad ja tööstuspiirkonnad seavad alumiiniumi kokku saasteainetega.

Nende hulka kuuluvad:

- Väävliühendid

- Happeline vihm

- Tolmuosakesed

Saaste nõrgestab kaitsvaid oksiidikihte ja katteid.

Kuum ja kuiv kliima

Kõrge temperatuur üksi ei kahjusta alumiiniumi kiiresti.

Siiski:

- UV-kiirgus mõjutab katteid

- Liiva hõõrdumine kahjustab pindu

- Suured temperatuurimuutused koormavad liigeseid

Vastupidavus sõltub pinnakaitse kvaliteedist.

Külm ja külma- ja sulaperioodid

Külma kliimaga kaasnevad erinevad riskid.

Külmumis-sulamistsüklid põhjustavad:

- Vee laienemine lõhedes

- Kattekihi pragunemine

- Tihendi rike

Alumiinium ise püsib stabiilsena, kuid katted ja kinnitusdetailid kannatavad.

Kliimamõjude võrdlus

| Kliima tüüp | Peamine risk | Vastupidavuse mõju |

|---|---|---|

| Rannikuala | Soola korrosioon | Kõrge |

| Tööstuslik | Keemiline kokkupuude | Keskmine kuni kõrge |

| Aavik | UV ja kulumine | Keskmine |

| Cold | Soojuspinge | Keskmine |

Kliimatingimused mängivad alumiiniumist ekstrusiooni eluea puhul suurt rolli.Tõsi

Niiskus, sool, reostus ja temperatuur mõjutavad korrosiooni ja katte vastupidavust.

Alumiiniumprofiilid toimivad kõikides kliimatingimustes ühtmoodi.Vale

Erinevad kliimatingimused tekitavad erinevat keskkonnastressi.

Kas pinnakatted võivad pikendada keskkonna kestvust?

Pinnakaitse on sageli vahe lühikese eluea ja pika kasutusea vahel. Paljud ostjad keskenduvad sulamile ja unustavad katted.

Pinnakatted pikendavad oluliselt alumiiniumprofiilide keskkonnaalast vastupidavust, kaitstes pinda korrosiooni ja ilmastikutingimuste eest.

Alumiiniumkattematerjalide eesmärk

Katted toimivad tõketena.

Nad:

- Blokeerib niiskuse

- Vähendada kemikaalidega kokkupuutumist

- Aeglane oksüdeerumine

- Parandada UV-kindlust

Õige kate sobib keskkonnaga.

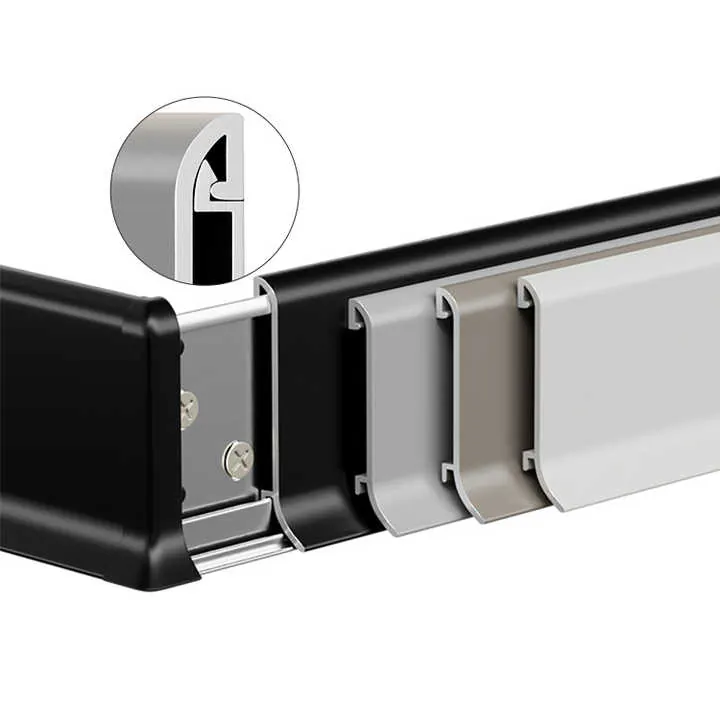

Anodeerimine vastupidavuse tagamiseks

Anodeerimine paksendab looduslikku oksiidikihti.

Eelised hõlmavad järgmist:

- Kõrge korrosioonikindlus

- Pole koorimist

- Pikaajaline stabiilsus

Paksem anodeerimine toimib paremini välitingimustes, eriti saastunud piirkondades.

Pulbrilise pinnakatte kaitse

Pulbriga katmine lisab polümeerikihi.

Eelised:

- Tugev värvi säilitamine

- Hea ilmastikukindlus

- Disaini paindlikkus

Selle vastupidavus sõltub katte paksusest ja eeltöötluse kvaliteedist.

PVDF-kate karmide keskkondade jaoks

PVDF-katteid kasutatakse äärmuslikuks kokkupuuteks.

Nad pakuvad:

- Suurepärane UV-kindlus

- Tugev keemiline stabiilsus

- Pikk kasutusiga

Need on levinud kõrgetasemelistes arhitektuuriprojektides.

Pinnakatte vastupidavuse võrdlus

| Pinnakatte tüüp | Välitingimustes vastupidavus | Hooldusvajadus |

|---|---|---|

| Anodeerimine | Kõrge | Madal |

| Pulbriga katmine | Keskmine kuni kõrge | Keskmine |

| PVDF | Väga kõrge | Madal |

Hooldus on endiselt oluline

Isegi kaetud alumiinium vajab hooldust.

Lihtsad tegevused aitavad:

- Perioodiline puhastamine

- Vältida abrasiivset kokkupuudet

- Drenaažipiirkondade kontrollimine

Katted aeglustavad kahjustusi, kuid ei peata aega.

Õige pinnakate võib oluliselt pikendada alumiiniumprofiili keskkonnaalast vastupidavust.Tõsi

Katted kaitsevad alumiiniumi niiskuse, kemikaalide ja UV-kiirguse eest.

Pinnakatted muudavad alumiiniumprofiilid igaveseks hooldusvabaks.Vale

Katted vähendavad kahjustusi, kuid nõuavad siiski põhihooldust.

Millised standardid hindavad välismaterjalide vastupidavust?

Vastupidavusnõudeid peavad toetama standardid. Ilma standarditeta kaotavad reitingud oma tähenduse.

Välitingimustes kasutatavus on määratletud rahvusvahelistes standardites, mis määravad kindlaks katsemeetodid ja toimivusastmed.

Ühised rahvusvahelised standardid

Erinevad piirkonnad tuginevad erinevatele süsteemidele.

Laialdaselt kasutatavad standardid on järgmised:

- ISO standardid

- ASTM standardid

- EN standardid

- AAMA spetsifikatsioonid

Need standardid määravad kindlaks, kuidas teste tehakse ja kuidas tulemused esitatakse.

ISO vastupidavusnormid

ISO standardid keskenduvad ülemaailmsele järjepidevusele.

Nad katavad:

- Korrosioonikatsed

- Katte paksus

- Pinnatöötluse kvaliteet

ISO standardid on rahvusvahelises kaubanduses laialdaselt tunnustatud.

ASTM ja AAMA standardid

ASTM standardid on Põhja-Ameerikas levinud.

Nad määratlevad:

- Soolapihustuse kestus

- Kokkupuude ilmastikuga

- Tulemuslikkuse võrdlusnäitajad

AAMA standardid keskenduvad arhitektuurialumiiniumile ja katetele.

EN standardid Euroopas

EN standardid klassifitseerivad:

- Pinnatöötluse kvaliteet

- Keskkonnakindlus

- Oodatavad jõudlustasemed

Neid nõutakse sageli ehitusprojektide puhul.

Standardite valik rakenduse järgi

| Taotlus | Tüüpiline standard |

|---|---|

| Arhitektuur | ET, AAMA |

| Tööstuslik | ISO, ASTM |

| Infrastruktuur | ISO, EN |

| Ekspordiprojektid | ISO |

Nõuetele vastavuse tähtsus

Standardid aitavad ostjaid:

- Võrdle tarnijaid

- Kontrollida vastupidavusnõudeid

- Projekti riski vähendamine

Ilma standardite järgimata on vastupidavuse hinnangud ebausaldusväärsed.

Keskkonnakindluse hinnangud põhinevad tunnustatud rahvusvahelistel standarditel.Tõsi

Standardid määratlevad katsemeetodid ja toimivuskriteeriumid.

On olemas üks universaalne vastupidavusstandard, mida kasutatakse kogu maailmas.Vale

Erinevad piirkonnad kasutavad erinevaid standardeid sõltuvalt rakendusest.

Kokkuvõte

Alumiiniumi ekstrusiooni keskkonna vastupidavus sõltub katsetustest, kliimast, katetest ja standarditest. Õige hindamise ja kaitse korral on alumiiniumprofiilidel pikk kasutusiga isegi karmides väliskeskkondades.