Alumiiniumist ekstrusioon kasvuhoone raamide jaoks?

Greenhouses are becoming more important in modern agriculture, and choosing the right materials for their construction is crucial. Aluminum extrusion is a material that’s been gaining traction. But why?

Aluminum is commonly used for greenhouse frames because it offers a unique combination of lightweight durability and corrosion resistance, which is essential for structures exposed to outdoor elements and chemicals.

Let’s dive deeper into why aluminum is an ideal choice for greenhouse structures and explore the specific advantages it offers to growers.

Why is aluminum commonly used in greenhouse structures?

When choosing materials for greenhouses, it’s important to consider weight, strength, and resistance to corrosion. Aluminum ticks all the boxes, but what makes it stand out?

Aluminum is favored in greenhouse structures for its lightness, strength, and ability to withstand harsh environmental conditions, making it ideal for long-term outdoor use.

Aluminum’s strength-to-weight ratio is one of the key reasons it’s used in greenhouse frames. Despite being lightweight, aluminum is strong enough to support heavy glazing materials like glass or polycarbonate. Its strength ensures that the structure will remain stable over time, even in harsh weather conditions.

Another significant advantage of aluminum is its resistance to corrosion. Unlike steel, which can rust over time, aluminum forms a natural oxide layer when exposed to air. This oxide layer protects the metal from further corrosion, making it perfect for outdoor environments. In a greenhouse, the constant exposure to moisture, humidity, and chemicals like pesticides and fertilizers can cause other materials to degrade. Aluminum’s corrosion resistance ensures it will last much longer, reducing the need for costly repairs or replacements.

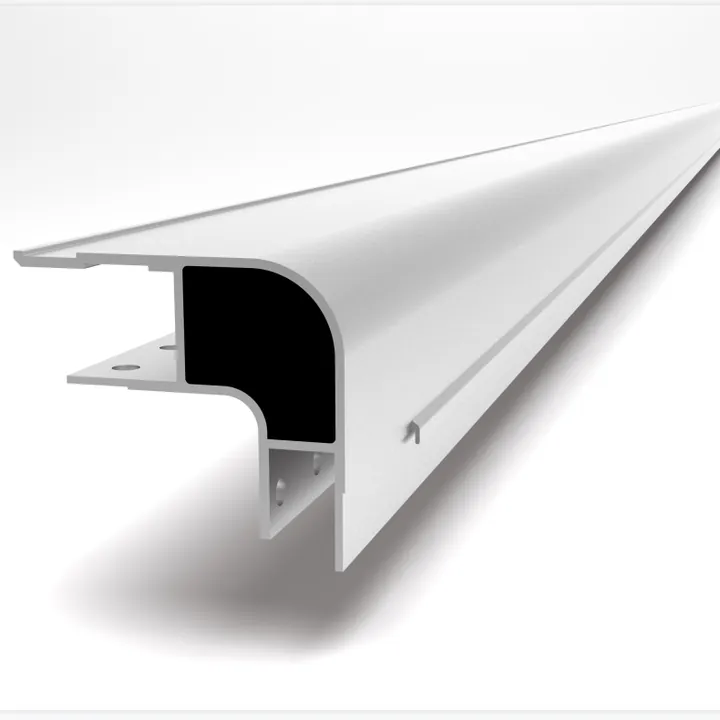

Aluminum’s versatility is also worth mentioning. Extrusions can be molded into a variety of shapes and profiles, allowing for custom greenhouse designs. Whether you need a simple frame or a more complex structure, aluminum can be easily adapted to meet the needs of different greenhouse styles. From small-scale hobbyist setups to large commercial operations, aluminum extrusions can be tailored to provide the necessary support and functionality.

In terms of sustainability, aluminum is 100% recyclable. This makes it an eco-friendly option for those looking to reduce their environmental impact. The recycling process requires only a small fraction of the energy needed to produce new aluminum, which further reduces the overall environmental footprint of greenhouse construction.

Aluminum is resistant to corrosion and ideal for outdoor use in greenhouses.Tõsi

Aluminum's natural oxide layer provides protection from corrosion, making it perfect for harsh environments like greenhouses.

Aluminum is too weak for large greenhouse structures.Vale

Despite its lightweight properties, aluminum is strong enough to support large greenhouse structures, making it a viable option for both small and large-scale operations.

What profiles provide optimal light support?

The design of greenhouse frames is critical, especially when it comes to maximizing light exposure. Aluminum profiles are key to achieving the best light support. How do they help?

Aluminum profiles are designed to securely hold greenhouse glazing materials, maximizing light transmission while maintaining structural integrity. Different profiles are chosen depending on the greenhouse design and specific light requirements.

The role of aluminum profiles in a greenhouse is not just about structure; it’s also about how they support light. Aluminum extrusions are commonly used to frame the glazing materials, whether they are glass, polycarbonate, or acrylic. These materials allow sunlight to penetrate the greenhouse, which is essential for plant growth. However, the frame must also be strong enough to support the weight of these materials without compromising light transmission.

Common aluminum profiles used for greenhouse frames include T-shaped, U-shaped, and L-shaped designs. T-shaped profiles are often used to hold the glazing panels in place along their edges, creating a tight seal that helps prevent air and moisture from escaping. U-shaped profiles can be used for the same purpose but provide a different aesthetic and structural support. L-shaped profiles, on the other hand, are useful for corners or intersections where the frame needs to meet at a 90-degree angle.

When selecting the right profile, it’s essential to consider the material being used for the glazing. For example, polycarbonate panels are lightweight but can be prone to bowing over time. A stronger aluminum profile is necessary to ensure these panels are adequately supported. In contrast, glass panels are heavier and require a more robust frame to prevent breakage or sagging.

Aluminum profiles also contribute to the overall energy efficiency of the greenhouse. Some extrusions are designed to minimize the amount of heat lost through the frame, helping maintain a stable internal temperature. This is especially important in climates where temperature fluctuations can impact plant health. Aluminum’s thermal efficiency, combined with the right profile, can enhance the greenhouse’s ability to retain heat and provide optimal growing conditions.

Different aluminum profiles are used to support various types of glazing materials in greenhouses.Tõsi

T-shaped, U-shaped, and L-shaped profiles are common choices for supporting glass, polycarbonate, and acrylic panels in greenhouses.

Aluminum profiles do not contribute to energy efficiency in greenhouses.Vale

Aluminum profiles can help improve energy efficiency by reducing heat loss, making the greenhouse environment more stable for plant growth.

Can extrusions resist agricultural chemicals?

Greenhouses involve frequent exposure to fertilizers, pesticides, and other chemicals. This raises the question: can aluminum extrusions resist agricultural chemicals, or are they susceptible to damage?

Yes, aluminum extrusions are resistant to many common agricultural chemicals, making them an ideal choice for greenhouse environments where exposure to chemicals is frequent.

One of the significant advantages of aluminum extrusions is their natural resistance to corrosion, which extends to many agricultural chemicals. Greenhouse environments often involve regular use of fertilizers, pesticides, herbicides, and other chemicals. Some of these substances can be quite corrosive, especially when exposed to metal frames over long periods.

Aluminum, however, is known for its resilience in these conditions. The metal’s oxide layer acts as a protective barrier against many chemicals, preventing degradation. For instance, aluminum extrusions are generally resistant to substances like nitrogen-based fertilizers, pesticides, and herbicides, all of which are commonly used in greenhouses.

That being said, some chemicals can still affect aluminum over time, particularly in high concentrations or under extreme conditions. Strong acids and alkalis, for example, may slowly break down the protective oxide layer. However, this is not typically a concern with the types of chemicals most commonly used in greenhouse operations. To further enhance aluminum’s chemical resistance, some manufacturers apply additional coatings or anodization treatments, which can make the material even more durable.

In comparison to other materials, aluminum performs exceptionally well. Steel, for example, tends to rust when exposed to moisture and chemicals, which can weaken the structure. In contrast, aluminum’s resistance ensures that it remains strong and functional for a much longer period, reducing the need for repairs or replacements.

Aluminum is resistant to most agricultural chemicals used in greenhouses.Tõsi

The natural oxide layer of aluminum helps protect it from degradation caused by common fertilizers and pesticides.

Agricultural chemicals will quickly corrode aluminum extrusions.Vale

Aluminum's oxide layer protects it from most agricultural chemicals, making it more resistant than other metals like steel.

Are extrusions suitable for large-scale greenhouses?

As the size of greenhouses grows, so do the demands on the materials used. Can aluminum extrusions handle the scale of large commercial greenhouses?

Aluminum extrusions are well-suited for large-scale greenhouses due to their strength, versatility, and the ability to be customized for specific structural needs.

When it comes to large-scale greenhouses, the material choice is crucial for both durability and cost-efficiency. Aluminum extrusions are a top choice for these large structures, providing the necessary strength without the weight and expense of other materials like steel.

Aluminum’s versatility allows it to be tailored for a variety of greenhouse designs. Large-scale operations require frames that can support not just the glazing but also other elements like irrigation systems, ventilation, and internal shelving. Aluminum extrusions can be custom-designed to meet these needs, offering strong support without unnecessary weight. This is particularly important in commercial operations, where every pound of material must contribute to the overall structure’s stability.

In addition to strength, aluminum extrusions offer ease of installation. The lightweight nature of aluminum reduces transportation costs and simplifies the assembly process, which is vital when constructing large greenhouses. Fewer workers are needed to handle and install the frames, which can significantly reduce labor costs during the build phase.

Moreover, aluminum’s resistance to corrosion means that even large-scale greenhouses exposed to harsh weather conditions can maintain their integrity for years. This is a critical factor for commercial growers who need to minimize maintenance costs and downtime. Aluminum’s long lifespan and minimal upkeep requirements make it a smart investment for any large-scale greenhouse project.

Aluminum extrusions are suitable for large-scale greenhouse structures.Tõsi

Aluminum’s strength, customization options, and ease of installation make it ideal for large greenhouse operations.

Aluminum is too weak for large greenhouse frames.Vale

Aluminum's strength-to-weight ratio makes it capable of supporting large greenhouse structures without compromising stability.

Kokkuvõte

In summary, aluminum extrusions offer several advantages for greenhouse structures. They are lightweight, strong, and resistant to corrosion, making them an excellent choice for both small and large greenhouses. Additionally, they can withstand agricultural chemicals and support different glazing materials to optimize light transmission, making them a top choice for sustainable, long-term greenhouse solutions.