What Are the Essential Basics of Aluminum Profiles?

Ever paused to think about the unsung heroes of the construction world? Aluminum profiles are everywhere, quietly supporting countless structures while often going unnoticed.

The essential basics of aluminum profiles include their lightweight nature, corrosion resistance, excellent strength-to-weight ratio, and versatility in applications. These properties make them a top choice in industries ranging from construction to automotive.

While these core attributes define the importance of aluminum profiles, there’s much more to uncover about how they are manufactured, their various types, and specific uses across different sectors. Dive deeper to explore these facets and enhance your understanding.

Aluminum profiles are heavier than steel.False

Aluminum profiles are lighter than steel, making them ideal for weight-sensitive applications.

How Are Aluminum Profiles Manufactured?

The manufacturing process of aluminum profiles is a fascinating blend of science and engineering, turning raw material into versatile structures.

Aluminum profiles are manufactured through extrusion, where heated aluminum billets are forced through a die to form specific shapes. This process is followed by cooling, straightening, and cutting to precise lengths. It allows for the creation of complex cross-sections while maintaining material strength and integrity.

The Aluminum Extrusion Process

The journey of aluminum profiles1 begins with aluminum billets. These cylindrical blocks of aluminum are heated to around 900°F (482°C) until they become malleable. The extrusion process involves forcing this softened aluminum through a steel die using a hydraulic press, which can exert thousands of tons of pressure. This results in the formation of a long piece with a consistent cross-sectional profile.

Types of Dies and Their Impact

- Solid Dies: These create simple shapes without any enclosed voids.

- Hollow Dies: Used for shapes that need internal cavities, such as tubes.

- Semi-Hollow Dies: Ideal for shapes that are mostly solid but have some hollow sections.

The choice of die impacts the complexity and type of profile produced. Each die must be designed with precision to ensure the profile meets specific application requirements.

Cooling and Straightening

After extrusion, the aluminum profile emerges at high temperatures and must be cooled quickly to retain its properties. This is often done using air or water baths. Once cooled, the profiles are straightened to correct any bends or twists that occurred during extrusion. This step ensures dimensional accuracy and prepares the profiles for cutting.

Precision Cutting and Finishing

Profiles are then cut into required lengths. The precision of these cuts is critical, especially when the profiles will be used in applications requiring tight tolerances. Post-extrusion, profiles may undergo further processes such as anodizing or powder coating to enhance corrosion resistance and improve aesthetic appeal.

Quality Control Measures

Every stage of manufacturing is subject to rigorous quality checks. These include dimensional inspections, surface finish evaluations, and mechanical testing to ensure each profile meets industry standards.

Understanding this manufacturing process highlights why aluminum profiles are so versatile and widely used across industries like aerospace, construction, and automotive.

Aluminum profiles are made by cold extrusion.False

Aluminum profiles are made by hot extrusion, not cold.

Hollow dies create aluminum profiles with internal cavities.True

Hollow dies are used to form shapes with enclosed voids, like tubes.

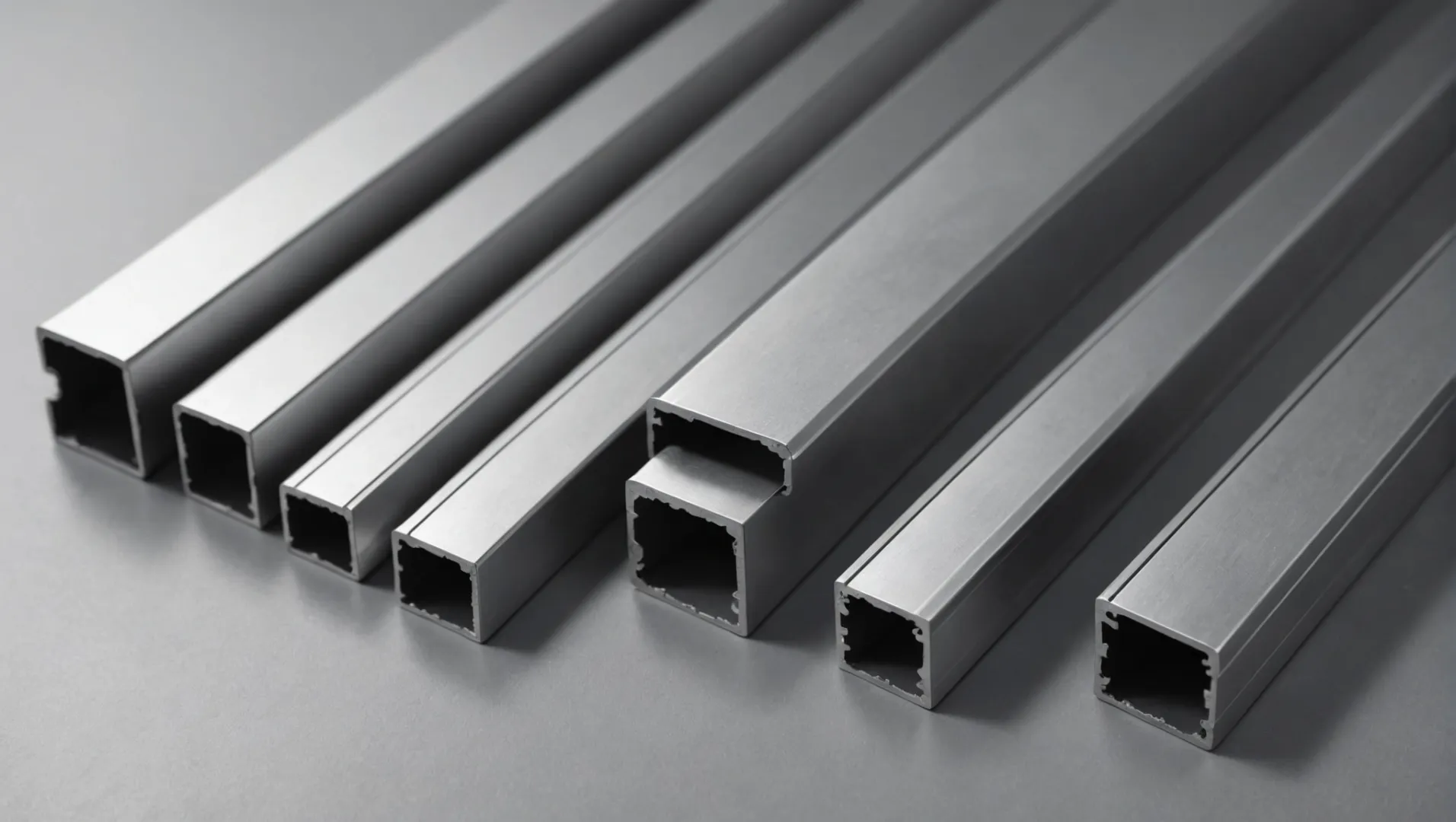

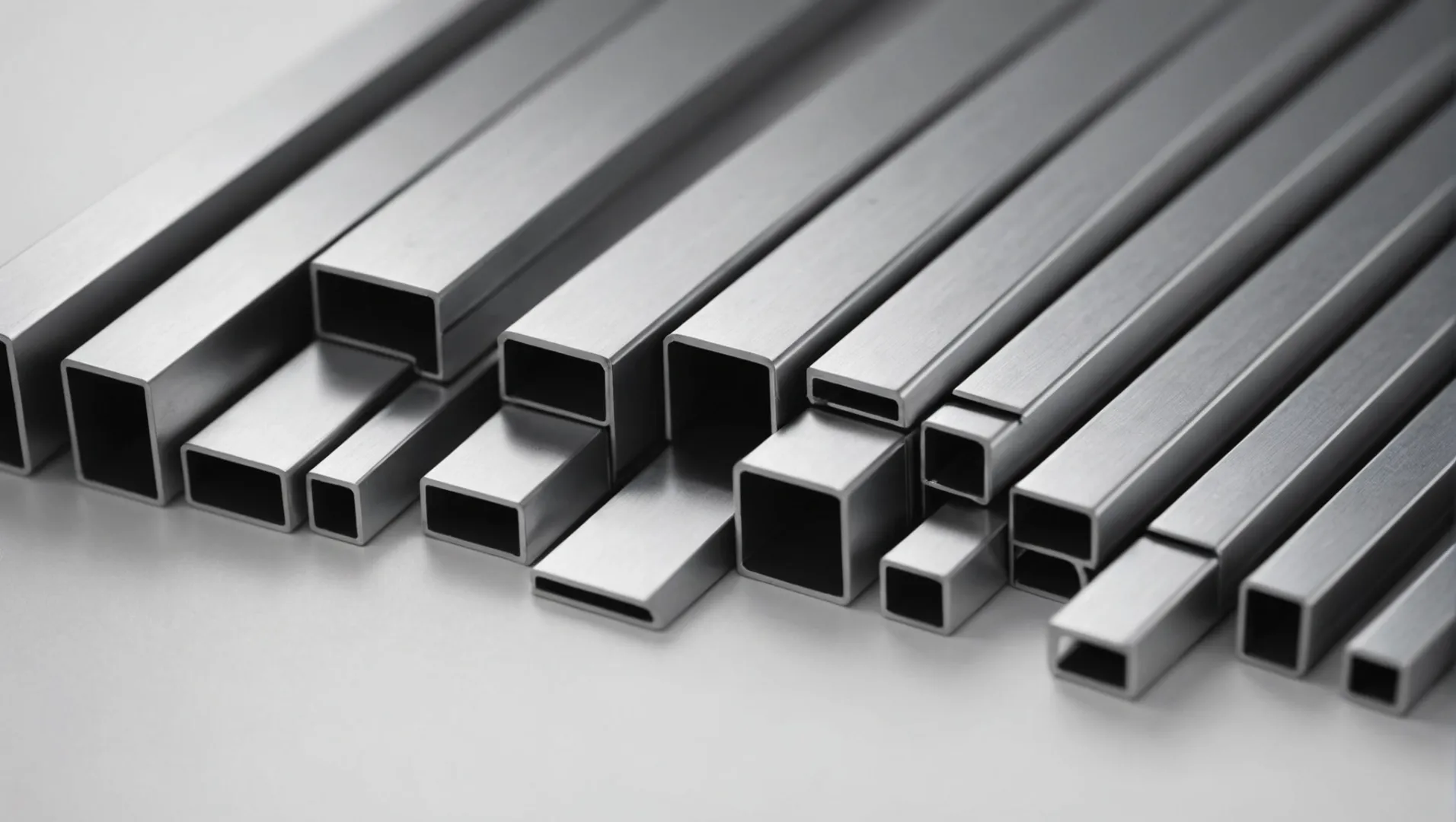

What Are the Different Types of Aluminum Profiles?

Discovering the diverse types of aluminum profiles helps in selecting the right one for your project.

Aluminum profiles come in various types, including standard profiles like angles and channels, custom-designed profiles tailored to specific applications, and structural profiles used in load-bearing applications. Each type serves unique purposes across industries.

Understanding Aluminum Profiles: An Overview

Aluminum profiles are extruded shapes of aluminum that are widely used in numerous applications due to their durability and lightweight properties. They come in a variety of shapes and sizes, offering designers and engineers the flexibility to meet specific needs. The types of aluminum profiles can be broadly categorized into several distinct groups, each serving different functions in industrial and commercial applications.

Standard Aluminum Profiles

Standard profiles are perhaps the most commonly encountered type. They include a variety of shapes such as:

- Angles: Used primarily for support structures and brackets.

- Channels: Often found in framing applications and construction projects.

- Tubes and Rods: Utilized in frameworks and mechanical components.

These profiles are easily accessible and versatile, making them a favorite choice in general engineering and construction tasks.

Custom-Designed Aluminum Profiles

Custom profiles are tailored to meet specific design criteria. They offer several advantages:

- Unique Designs: Allowing for specialized shapes that meet particular requirements.

- Increased Efficiency: Can reduce the need for additional components, simplifying assembly processes.

Custom profiles are often used in innovative industries such as aerospace and automotive, where precision engineering2 is crucial.

Structural Aluminum Profiles

Structural profiles are designed for load-bearing applications. They include:

- I-Beams: Commonly used in construction for their strength.

- T-Slots: Provide flexibility for adjustable frame construction.

These profiles are engineered to withstand significant stress and are integral to many architectural and industrial designs.

Architectural Aluminum Profiles

Architectural profiles are used extensively in building design. They often include:

- Window Frames: Offering both strength and aesthetic appeal.

- Curtain Walls: Essential for modern building facades.

Their application extends beyond mere functionality, contributing to both the structural integrity and visual design of buildings.

Summary Table of Aluminum Profile Types:

| Type | Common Uses |

|---|---|

| Standard Profiles | General construction, mechanical parts |

| Custom Profiles | Specialized industry requirements |

| Structural Profiles | Load-bearing structures |

| Architectural | Building aesthetics and structures |

Exploring these diverse types of aluminum profiles reveals their adaptability across a wide range of applications, proving their indispensability in modern engineering.

Standard profiles include angles and channels.True

Angles and channels are commonly used standard aluminum profiles.

Architectural profiles are not used in building design.False

Architectural profiles are extensively used in building design.

Why Choose Aluminum Profiles Over Other Materials?

Aluminum profiles offer unmatched benefits, making them a preferred choice across industries. But why exactly are they favored over other materials?

Aluminum profiles are chosen over other materials due to their lightweight nature, superior corrosion resistance, excellent strength-to-weight ratio, and remarkable versatility. These characteristics make them ideal for diverse applications, from construction to transportation.

Superior Corrosion Resistance

One of the standout features of aluminum profiles is their natural corrosion resistance. Unlike steel3, which requires additional coatings to prevent rust, aluminum forms a protective oxide layer naturally. This layer protects the metal from further oxidation and corrosion, making it particularly beneficial in environments exposed to moisture or saltwater.

Exceptional Strength-to-Weight Ratio

Aluminum boasts an impressive strength-to-weight ratio, which means it offers significant structural strength without the burden of weight. This property is crucial in aerospace4 and automotive industries where reducing weight enhances fuel efficiency without compromising safety.

| Material | Strength-to-Weight Ratio |

|---|---|

| Aluminum | High |

| Steel | Moderate |

| Copper | Low |

Versatility in Applications

The versatility of aluminum profiles cannot be overstated. They can be extruded into a multitude of shapes and sizes, making them adaptable for various design requirements. Whether in the form of intricate architectural designs or simple industrial frameworks, aluminum profiles can meet diverse needs with ease.

Eco-Friendly Attributes

Aluminum is 100% recyclable without loss of quality. This makes it an environmentally friendly choice, aligning with global efforts towards sustainability. Recycling aluminum requires only 5% of the energy used in primary production, significantly reducing its environmental footprint.

Cost-Effectiveness

While the initial cost of aluminum may be higher than materials like steel, its longevity and reduced maintenance needs often result in lower lifecycle costs. For instance, construction projects5 using aluminum profiles benefit from decreased replacement and repair expenses over time.

In summary, aluminum profiles outshine other materials due to their unmatched combination of strength, durability, and adaptability. As industries continue to evolve, the demand for materials that offer both performance and sustainability is likely to keep aluminum at the forefront.

Aluminum profiles have a high strength-to-weight ratio.True

Aluminum offers significant strength without added weight, crucial for efficiency.

Steel naturally resists corrosion better than aluminum.False

Aluminum forms a natural oxide layer that resists corrosion, unlike steel.

How Do Aluminum Profiles Benefit Construction Projects?

Discover how aluminum profiles revolutionize modern construction with their unmatched benefits.

Aluminum profiles enhance construction projects by offering strength, lightweight properties, corrosion resistance, and design flexibility. These attributes allow for more innovative designs, reduced structural weight, and lower maintenance costs, making aluminum a preferred choice for architects and builders.

Strength and Lightweight Properties

One of the primary advantages6 of using aluminum profiles in construction is their exceptional strength-to-weight ratio. This characteristic is crucial for creating robust structures without the burden of excessive weight, enabling the design of larger spans and unique architectural forms that might be impossible with heavier materials.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that resists corrosion, making it ideal for projects exposed to harsh environmental conditions. Unlike steel, which requires additional coatings to prevent rust, aluminum maintains its integrity with minimal upkeep, reducing long-term maintenance costs significantly.

Design Flexibility

With the ability to be extruded into a wide variety of shapes and sizes, aluminum profiles offer unparalleled design flexibility. This versatility allows architects to implement intricate designs and custom solutions tailored to specific project needs. For instance, curtain walls and window frames benefit from this adaptability, enhancing both aesthetics and functionality.

Energy Efficiency

Incorporating aluminum profiles into construction can lead to improved energy efficiency. Their excellent thermal insulation properties contribute to better building energy performance, helping achieve stringent energy codes and green building certifications. This is particularly beneficial in the context of sustainable architecture, where reducing energy consumption is paramount.

Cost-Effectiveness

Although the initial cost of aluminum might be higher than some traditional materials, its durability and low maintenance requirements often lead to greater overall cost-effectiveness. The reduction in material weight also lowers transportation and installation costs, adding further economic benefits to construction projects.

Enhanced Aesthetics

The sleek appearance of aluminum profiles enhances the aesthetic appeal of modern buildings. Their ability to be anodized or powder-coated in various finishes allows for a wide range of visual effects, from high-gloss metallic sheens to matte textures. This adaptability means that aluminum can complement any architectural style while offering a modern touch.

Aluminum profiles are heavier than steel.False

Aluminum profiles are lighter, offering a better strength-to-weight ratio.

Aluminum profiles require frequent maintenance.False

Aluminum resists corrosion naturally, reducing maintenance needs.

Conclusion

Understanding aluminum profiles’ basics empowers informed decisions in projects. Explore further to master their applications and unlock potential in design and manufacturing. Ready to dive deeper into this versatile material?

-

Explore how die design impacts the profile’s shape and complexity.: They are normally constructed from H-13 die steel and heat-treated to withstand the pressure and heat of hot aluminum as it is pushed through the die. While it … ↩

-

Explore how custom designs can enhance efficiency and reduce costs.: In the world of custom aluminum products, designing a custom profile means shorter lead times due to less fabrication and finishing work that … ↩

-

Understand how aluminum’s natural oxide layer prevents rust unlike steel.: TIL aluminum is so corrosion resistant because where iron and steel rust, Al combines with oxygen to form a material even harder than aluminum … ↩

-

Discover why lightweight materials are critical for aerospace efficiency.: Lighter and/or stronger materials allow greater range and speed and may also contribute to reducing operational costs. ↩

-

Learn how aluminum’s properties enhance construction projects.: Benefits of aluminum include those such as durability, flexibility, thermal performance, and a reduced environmental impact. ↩

-

Explore detailed comparisons of aluminum’s strength-to-weight ratio benefits.: The main benefit of aluminum is a higher ratio of strength density compared to common steel alloys. Replacing steel with aluminum can give a weight reduction. ↩