¿Cómo prevenir la corrosión del aluminio?

Aluminum is lightweight and strong, but corrosion can silently damage it. Ignoring it could ruin equipment, increase costs, and shorten product life.

You can prevent aluminum corrosion with smart material selection, protective coatings, and regular maintenance. These steps help your aluminum components last longer, especially in harsh conditions.

Many industries depend on aluminum. But not all understand how to protect it well. Let’s explore how you can prevent corrosion and protect your investments.

¿Qué causa la corrosión del aluminio?

Corrosion doesn’t always start with cracks or visible damage. In fact, some of the most dangerous aluminum corrosion begins underneath the surface.

Aluminum corrodes mainly due to exposure to moisture, oxygen, and certain chemicals, especially in salty or acidic environments.

When aluminum is exposed to air, it forms a thin oxide layer that normally protects it. But in environments with salt, pollution, or acid rain, this layer breaks down. This leads to pitting corrosion, which is small but deep and can destroy structural integrity.

Causas comunes de la corrosión del aluminio

| Causa | Descripción |

|---|---|

| Humedad | Water enables electrochemical reactions. |

| Salt (e.g., sea air) | Salt ions break down aluminum’s oxide layer. |

| Acidic pollutants | Industrial gases like SO2 can react with aluminum surfaces. |

| Dissimilar metals contact | Galvanic corrosion occurs when aluminum touches copper, steel, etc. |

Another major reason is improper handling during storage or production. Leaving aluminum uncoated or storing it in high-humidity areas can speed up corrosion. Also, mechanical damage can scratch away its oxide layer, exposing raw metal to the environment.

Aluminum corrodes easily even in dry indoor conditions.Falso

In dry indoor environments, aluminum generally forms a stable oxide layer that prevents further corrosion.

Salt and acid can damage aluminum by breaking its natural oxide protection.Verdadero

Chloride and acidic substances weaken the protective layer and cause localized corrosion like pitting.

Does anodizing stop aluminum corrosion?

Many manufacturers think aluminum is already corrosion-resistant. But in tough conditions, that natural layer is not enough.

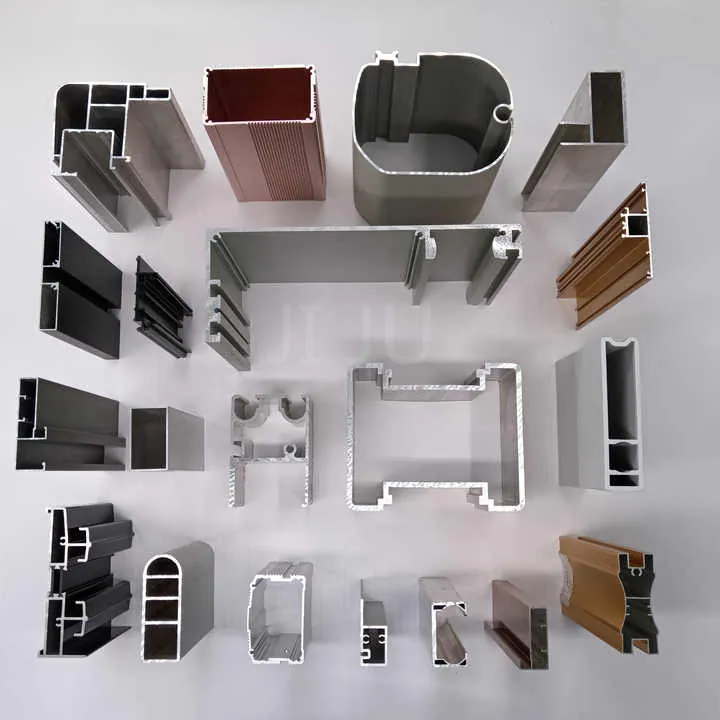

Anodizing significantly increases aluminum’s resistance to corrosion by thickening its natural oxide layer and sealing it against external damage.

Anodizing is an electrochemical process. It thickens the natural aluminum oxide on the surface. This oxide acts like armor. It’s not just a coating—it becomes part of the metal. This makes it much harder for water or chemicals to penetrate.

Anodizing is especially useful in environments with high humidity, sea salt, or chemical exposure. It doesn’t peel or flake like paint. You can also dye anodized aluminum for aesthetic or coding purposes.

Key Benefits of Anodizing

| Ventaja | Cómo ayuda |

|---|---|

| Harder surface | More scratch-resistant than untreated aluminum. |

| Better corrosion defense | Thicker oxide layer blocks moisture and chemicals. |

| Color y aspecto | Can be dyed without affecting corrosion resistance. |

| Environmentally safe | No toxic chemicals or heavy metals involved. |

However, anodizing is not magic. If it’s scratched or poorly sealed, corrosion can still occur. So it’s important to follow quality control during the process. Always choose a trusted supplier with ISO-standard anodizing lines.

Anodizing only changes the color of aluminum but doesn't affect corrosion resistance.Falso

Anodizing increases corrosion resistance by building a thicker oxide layer on the aluminum surface.

Anodizing makes the aluminum surface harder and more durable.Verdadero

The anodized oxide layer is harder than bare aluminum and resists scratches and corrosion.

How to maintain aluminum in humid environments?

Humidity is a quiet enemy of metals. Aluminum may resist rust, but high moisture levels still challenge its surface.

To maintain aluminum in humid environments, keep it clean, dry, and coated with a protective layer like anodizing, powder coating, or regular waxing.

Humidity encourages water molecules to settle on surfaces. This can break down aluminum’s oxide layer over time. Add salt or pollution, and corrosion speeds up. If you live near the ocean or work in industrial zones, maintenance becomes essential.

Tips to Protect Aluminum in Humid Climates

- Keep it clean: Use fresh water and mild detergent. Dirt traps moisture.

- Dry it often: After cleaning or rain, wipe aluminum dry with soft cloths.

- Inspección periódica: Look for white spots or surface bubbles. These are early corrosion signs.

- Aplicar revestimientos protectores: Wax, oil films, or nano-coatings can create a water-resistant barrier.

- Use drainage-friendly designs: Avoid water pooling. Design holes and channels for water to escape.

Comparison of Maintenance Options

| Método | Pros | Contras |

|---|---|---|

| Wax/oil film | Easy to apply, water-repellent | Needs reapplication every few months |

| Recubrimiento en polvo | Strong barrier, aesthetic options | Can chip or peel if damaged |

| Nano-coatings | Invisible protection, long-lasting | More expensive |

| Limpieza regular | Removes salt/dust | Trabajo intensivo |

Humidity also promotes galvanic corrosion when aluminum touches other metals like copper or brass. Always isolate aluminum from other metals using plastic washers, rubber gaskets, or anodized fasteners.

Aluminum in humid areas should be left uncoated to maintain natural oxidation.Falso

Coatings help block moisture and extend aluminum’s life in humid environments.

Cleaning and drying aluminum regularly helps prevent corrosion in humid areas.Verdadero

Removing salt and moisture reduces the chance of corrosion developing on the surface.

Can protective coatings extend aluminum lifespan?

A thin layer of paint or sealant might seem small. But for aluminum, it could be the difference between years of use or premature failure.

Yes, protective coatings can extend aluminum’s lifespan by blocking moisture, chemicals, and scratches that would otherwise cause corrosion.

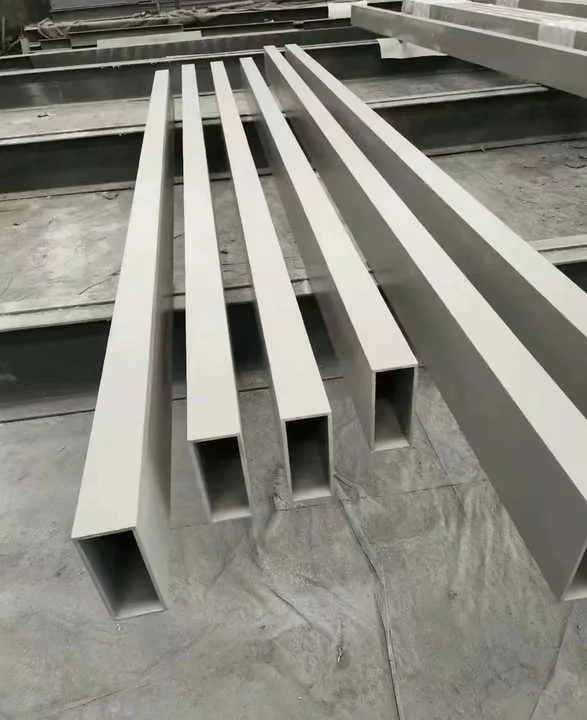

Protective coatings add a physical barrier. These can be paint, powder coat, anodized layer, or clear sealants. Each coating works differently, but all prevent direct contact between aluminum and the environment.

Common Coating Options

| Tipo de revestimiento | Caso práctico | Lifespan Estimate |

|---|---|---|

| Recubrimiento en polvo | Architectural parts, machinery | 15-20 años |

| Anodizado | Outdoor furniture, solar frames | 10-15 años |

| Clear lacquer | Interior decorative use | 3-5 años |

| Epoxy paint | Industrial, marine environments | 8-12 años |

Coating choice depends on application. For outdoor installations, powder coating or anodizing is best. For internal use, even a clear sealant can work.

Key is surface preparation. Without clean and dry aluminum, coatings won’t bond well. Also, damaged coatings must be repaired quickly. A small scratch can allow moisture inside, leading to hidden corrosion.

Protective coatings only improve aluminum's appearance and have no effect on durability.Falso

Coatings act as barriers that prevent corrosion, extending aluminum’s service life.

Powder coating can help aluminum components last more than a decade outdoors.Verdadero

When applied correctly, powder coating resists UV, moisture, and scratches for over 10 years.

Conclusión

Aluminum corrosion is manageable with the right tools and awareness. Use anodizing, regular maintenance, and protective coatings to ensure your aluminum products stay strong for years.