How Is a Car Radiator Made?

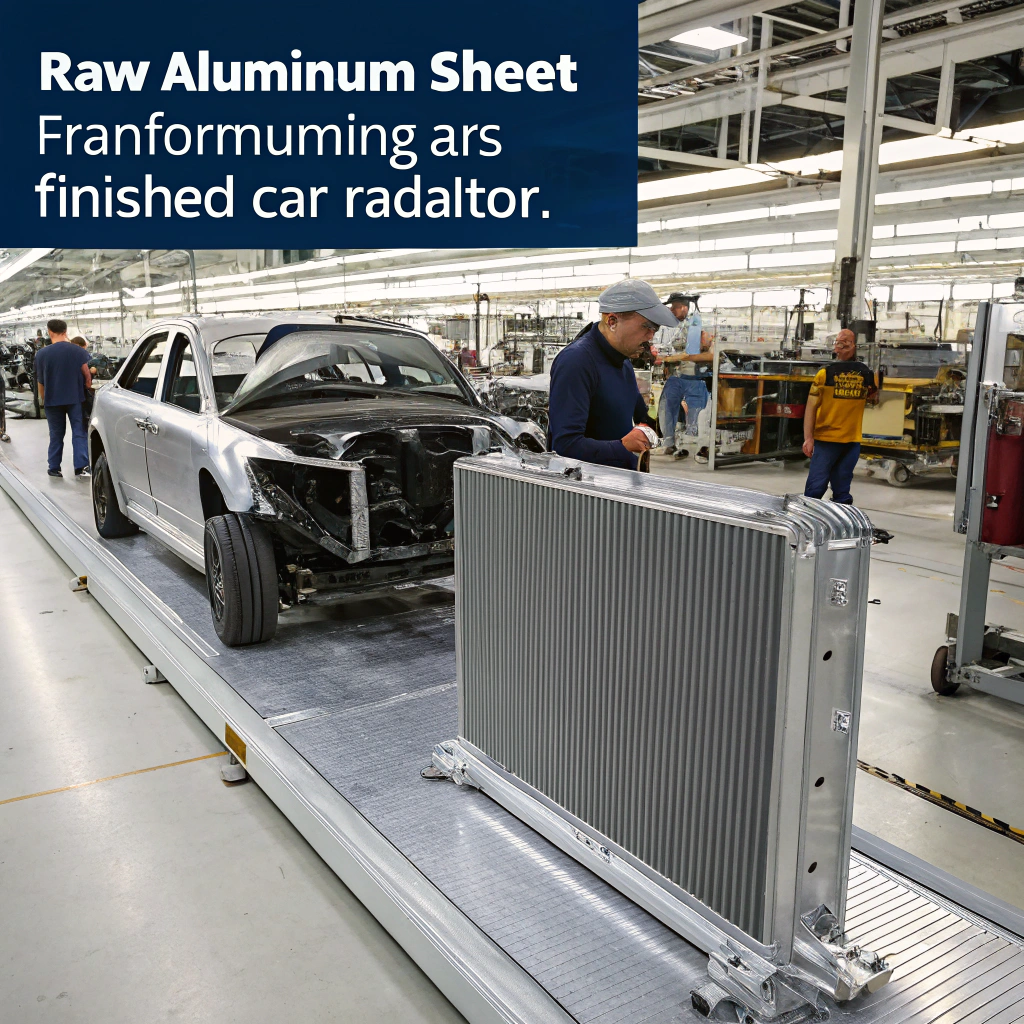

I once watched a raw aluminum sheet transform into a finished car radiator at a factory. It made me realize how much hidden engineering goes into something most drivers never think about.

A car radiator is built from aluminum, copper, and plastic using processes like stamping, brazing, crimping, and pressure testing. Every unit is engineered to withstand heat, pressure, and time.

What looks like a simple metal box is actually a complex, multi-stage manufacturing product. Let me walk you through what it’s made of, how it’s manufactured, and how it’s put together.

What Is a Car Radiator Made Of?

A few years ago, I dealt with a customer who insisted on copper radiators for all their industrial trucks. They had their reasons, but I realized then that not all radiators are created equal.

Most modern radiators are made of aluminum for the core and plastic for the tanks, while older or heavy-duty models may use copper or brass.

Common Radiator Materials

| Material | Área de aplicación | Pros | Contras |

|---|---|---|---|

| Aluminio | Fins, tubes, core frame | Lightweight, corrosion-resistant, cheap | Harder to repair |

| Copper/Brass | High-duty core and tanks | High conductivity, easy to repair | Heavier, more expensive |

| Plástico | Side tanks | Low cost, easy molding | Not heat-resistant over time |

| Steel Alloys | Specialty or custom units | Strong and durable | High cost, low thermal transfer |

Aluminum is now the dominant material due to its balance of cost, weight, and heat conductivity. Plastic tanks reduce cost but may be less durable under extreme heat.

Copper radiators are lighter than aluminum ones.Falso

Copper radiators are heavier due to the density of the metal.

Plastic is commonly used for radiator tanks.Verdadero

Modern radiators often use injection-molded plastic for the side tanks.

How to Manufacture Radiators?

When I toured a supplier’s facility in Zhejiang, I was surprised by the level of automation: cutting, forming, brazing—all lined up like clockwork.

Radiators are manufactured through metal stamping, tube and fin formation, core stacking, furnace brazing, tank assembly, and final testing.

Manufacturing Flow Explained

1. Material Cutting

Aluminum sheets are sliced into strips for tubes and fins.

2. Fin and Tube Forming

Machines stamp out fins and form tubes through rollers or presses.

3. Core Assembly

The tubes and fins are layered in alternating rows to create a dense thermal exchange surface.

4. Furnace Brazing

This stacked “core” is brazed in a nitrogen-filled furnace at 600°C to bond all components into one solid unit.

5. Tank Production

Plastic tanks are molded via injection molding; copper tanks are soldered or formed manually.

6. Crimping and Sealing

Tanks are attached to each end of the core using crimping equipment with gaskets to ensure leak-tight sealing.

7. Surface Coating

The assembled radiator is sprayed or dipped in anti-corrosion solutions if needed.

8. Leak & Pressure Testing

Each radiator undergoes a final test with air or fluid to detect micro-leaks.

Production Steps Table

| Escenario | Key Activity |

|---|---|

| Sheet Preparation | Cut aluminum to specific widths |

| Component Forming | Stamp fins and roll tubes |

| Core Stacking | Build alternating fin-tube structure |

| Brazing | Bond pieces in high-heat furnace |

| Montaje | Attach tanks and seal ends |

| Testing | Confirm pressure resistance |

Brazing is used to permanently fuse the core structure.Verdadero

Brazing creates a solid, sealed heat exchange structure.

Plastic tanks are glued to the aluminum core.Falso

Plastic tanks are mechanically crimped and sealed, not glued.

How Are Radiators Assembled?

When I watched the workers on the final assembly line, I noticed one thing: precision. Even 1mm misalignment could cause leaks or failure in the field.

Radiators are assembled by joining the brazed core with tanks using crimping machines, sealing gaskets, and testing for leaks under pressure.

Key Assembly Stages

Step 1: Core Inspection

The brazed core is cooled, inspected, and deburred for safety.

Step 2: Tank Alignment

Plastic or metal tanks are placed onto the headers on each side of the core.

Step 3: Crimping

The tanks are mechanically pressed onto the core, locking in the gaskets and forming a sealed structure.

Step 4: Testing

Radiators are connected to pressure devices that inject air or water to ensure they withstand at least 1.5x their operating pressure.

Step 5: Labeling and Packing

Units that pass all tests are tagged with barcodes, packed with protective covers, and boxed for shipping.

Tools and Machines Used

| Herramienta | Función |

|---|---|

| Crimping machine | Mechanically locks tanks to core |

| Leak tester | Checks for internal or seam leaks |

| Furnace (prior) | Performs brazing during core formation |

Assembly is where everything comes together. If done correctly, the radiator will last years under stress, heat, and vibration.

Crimping is used to attach plastic tanks to aluminum cores.Verdadero

Crimping secures the tank to the core with a tight mechanical lock.

Radiator cores are glued together with epoxy.Falso

Cores are brazed in high-temperature furnaces, not glued.

What Is the Process of a Car Radiator?

When customers ask about production time, I always explain it’s not just one machine—it’s a pipeline of operations that must flow in sync.

The full process includes cutting, forming, stacking, brazing, tank installation, pressure testing, and final packaging.

Summary of Radiator Production Process

| Etapa del proceso | Descripción |

|---|---|

| Material Prep | Aluminum sheets and plastic granules prepped |

| Fin/Tube Forming | Fins are stamped; tubes rolled or extruded |

| Core Assembly | Layering tubes and fins |

| Brazing Furnace | Heat joins all core components |

| Tank Manufacturing | Injection mold or metal form |

| Crimping Assembly | Tanks locked onto the brazed core |

| Pressure Testing | Unit is tested for leaks and durability |

| Embalaje final | Labeling, boxing, and logistics prep |

This is how a high-performance car radiator is born—from raw coil to precision cooling part—ready to manage engine heat even on the hottest days.

Radiators are assembled after all parts are brazed or formed.Verdadero

Only after brazing and forming are complete does the assembly process begin.

Radiators skip pressure testing to speed up production.Falso

Every radiator must pass pressure testing before being approved for shipping.

Conclusión

Car radiators are made through a multi-step, precision-driven process that transforms raw aluminum and plastic into reliable, high-performance cooling systems. Every stage—from forming to testing—ensures durability and efficiency on the road.