Does a laser marking machine need to use aluminum profiles?

Many people struggle to decide if they need aluminum profiles when setting up a laser marking station. The wrong decision can lead to unstable results and reduced productivity.

Yes, aluminum profiles are often used to build frames and support structures for laser marking machines because they provide strength, precision, and modularity.

If you’re unsure whether your laser system requires aluminum profiles or how they affect your process, read on—we’ll break it down step-by-step.

What are aluminum profiles in laser marking systems?

Many laser users think "laser" means just light and precision. But without proper structural support, even the best laser can fail to deliver.

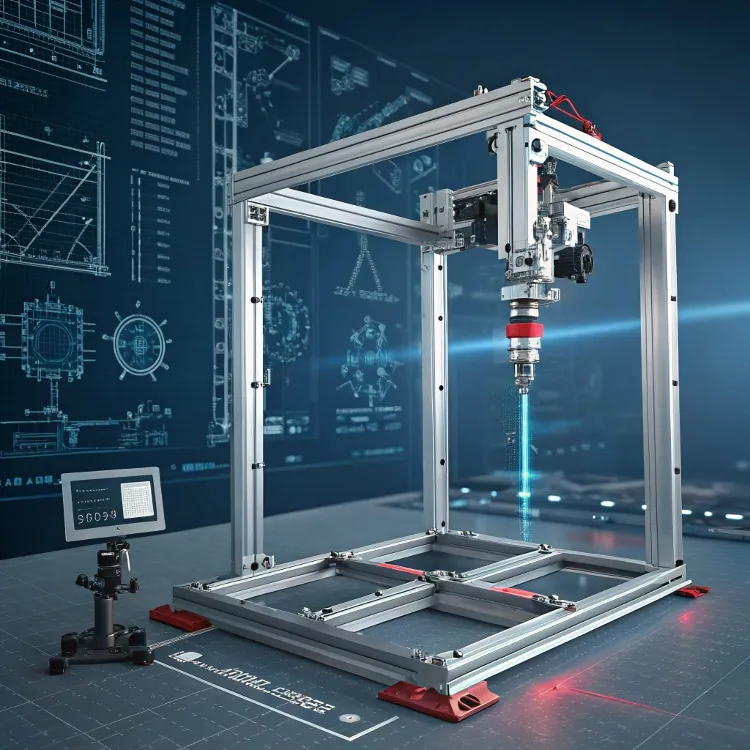

In laser marking systems, aluminum profiles are modular structures used to build machine frames, guide rails, and support fixtures.

Aluminum profiles in these machines work like the skeleton in the human body. They hold everything together. Most marking systems have a rigid base and adjustable arms or mounts. Aluminum profiles are popular because they’re strong, lightweight, and easy to cut and assemble.

Why manufacturers prefer aluminum profiles:

| Feature | Benefit |

|---|---|

| Lightweight | Easier to transport and modify |

| Corrosion-resistant | Long-lasting in factory settings |

| Modular | Allows flexible system design |

| Strong | Maintains laser head alignment |

These profiles usually come in standard T-slot designs, which allow attachments like sensors, fixtures, or protective enclosures. I remember working with a client who used a steel frame before switching to aluminum—it took two days to adjust the laser head previously. After switching, they did it in ten minutes.

Aluminum profiles in laser systems serve purely decorative purposes.False

They serve a structural and functional role, not just aesthetics.

Aluminum profiles are used to build the physical frame and support structure of laser marking machines.True

They provide the stability and flexibility needed for accurate laser marking.

Can laser markers work on irregular aluminum shapes?

Sometimes buyers think laser marking only works on flat surfaces. But real parts are rarely flat or perfect.

Yes, laser markers can mark irregular aluminum shapes using adjustable fixtures and dynamic focus control.

Not all aluminum shapes are square or flat. Some customers need to mark curved pipes, extrusions with fins, or even twisted brackets. Most advanced laser systems today can handle these shapes—but only with the right setup.

Key setup features for irregular marking:

1. Adjustable Fixtures

Laser systems often include clamps and mounts that hold irregular parts steady. Custom aluminum fixtures, built from T-slot profiles, are popular because they can be shaped to fit any curve.

2. Z-axis and Autofocus

Modern systems have moving heads that adjust focus automatically. This keeps the laser beam sharp even on sloped or curved surfaces.

3. Software Compensation

Some systems allow marking on 3D surfaces by adjusting the beam path. It’s not just about hardware—it’s about how you program the job.

| Feature | Role in Irregular Marking |

|---|---|

| Autofocus Lens | Maintains sharp marking on uneven surfaces |

| Rotary Axis | Helps mark on round or cylindrical parts |

| Custom Fixtures | Holds odd-shaped pieces securely |

I worked with a lighting company marking curved lamp housings. Their old setup caused blurry marks. Once we added a rotary axis and a custom fixture from aluminum profiles, the results were perfect.

Laser markers cannot handle curved or non-flat aluminum shapes.False

With proper tools like autofocus and adjustable mounts, they can mark curved surfaces accurately.

Laser markers can work on irregular aluminum shapes with the help of custom fixtures and focus controls.True

These adjustments allow precise marking even on complex geometries.

Do all laser machines require metal fixtures for marking?

Some users think plastic or wood fixtures are “good enough” to hold their parts. That’s risky.

Not all laser machines require metal fixtures, but metal is preferred for stability, durability, and heat resistance.

Fixtures are what hold the workpiece in place. Depending on the material and heat generated, the wrong fixture could burn, deform, or shift during marking. Metal fixtures—especially aluminum—are safe, durable, and easy to shape.

Comparing fixture materials:

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, non-magnetic, precise | Slightly more expensive |

| Steel | Very rigid | Heavy, prone to rust |

| Plastic | Cheap, easy to cut | Not heat resistant, less stable |

| Wood | Easy to shape | Burns, inconsistent holding force |

In our experience, metal fixtures are ideal for high-precision marking. For one client marking automotive parts, switching from plastic to aluminum fixtures reduced marking errors by 85%.

Some low-power lasers or DIY setups may get away with non-metal fixtures. But for B2B applications, especially when marking aluminum parts, I always recommend going with metal.

Plastic fixtures are the best option for all industrial laser marking applications.False

Plastic lacks the heat resistance and stability required for high-precision marking.

Metal fixtures, especially aluminum ones, are preferred in laser marking for their strength and heat resistance.True

They provide better alignment and repeatability.

How does using profiles impact marking speed and accuracy?

Many assume that software and laser quality alone determine marking performance. But mechanical stability is just as critical.

Using aluminum profiles improves both speed and accuracy by providing rigid, vibration-free support during marking operations.

Every part of the laser machine affects precision. The smoother and more stable the frame, the less vibration or movement occurs when the laser head moves. Aluminum profiles provide this base.

Effects of stability on performance:

A. Speed

When frames vibrate, operators must slow the marking process to avoid mistakes. A strong profile frame lets you run faster without sacrificing quality.

B. Accuracy

Profiles reduce wobble. A precise frame means repeatable marks every time—even in batch production.

C. Calibration

Aluminum profiles hold adjustments better than wood or plastic. You won’t need to recalibrate every time you run a job.

Here’s what one customer told us:

“After replacing our frame with 40×80 aluminum profiles, we increased marking speed by 20% and cut calibration time in half.”

| Factor | Without Aluminum Profile | With Aluminum Profile |

|---|---|---|

| Marking Speed | Slow (due to vibration) | Fast and stable |

| Accuracy | Inconsistent | Precise and repeatable |

| Downtime | High (recalibration needed) | Low (stable setup) |

Using aluminum profiles reduces vibration and allows for faster, more accurate laser marking.True

Stable structures mean less movement and better control of the laser beam.

Profiles have no impact on the speed or accuracy of laser marking.False

Mechanical stability directly affects performance, especially in high-speed or precision jobs.

Conclusion

Aluminum profiles play a vital role in laser marking systems. They offer support, flexibility, and precision that directly improve marking quality, speed, and system durability.