Startform 200KG

Tilbud og estimering

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Hjem > Røresvejsning af aluminium Producent

We deliver tailored FSW aluminum components that align precisely with your structural and performance requirements in industrial assemblies.

Produktion i stor skala:.Vores fabrik strækker sig over 1.000 mu (ca. 667.000 m²)med fuld in-house kapacitet fra aluminiumsmeltning og støbning af emner til ekstrudering, overfladebehandling og CNC-bearbejdning.

One-stop-løsning:.Med 43 ekstruderingslinjer (500-5500 tons) og en dedikeret skimmelpartner leverer vi hurtig produktion, tilpassede profiler og integrerede tjenester til forenkle din forsyningskæde.

Kvalitet, du kan stole på:.Streng kvalitetskontrol sikrer Ensartede dimensioner, styrke og finishDet reducerer din risiko og øger pålideligheden.

Hurtig levering og omkostningseffektivitet:.Egenproducerede billets, in-house forarbejdning og serieproduktion betyder hurtigere leveringstider og lavere samlede omkostninger.

Avancerede efterbehandlingsmuligheder:.Anodisering og både lodrette og vandrette pulverlakeringslinjer leverer holdbare overfladebehandlinger af høj kvalitet skræddersyet til dine produktbehov.

TRIN

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Oprettelse af en prototype for at vurdere dimensioner og sikre, at formens præcision stemmer overens med kravene.

Producerer aluminiumsprofilen med stor nøjagtighed i henhold til de givne specifikationer og anvender den ønskede finish.

Skræddersyet emballage til de ekstruderede profiler, der sikrer sikker og effektiv læsning til hurtig levering.

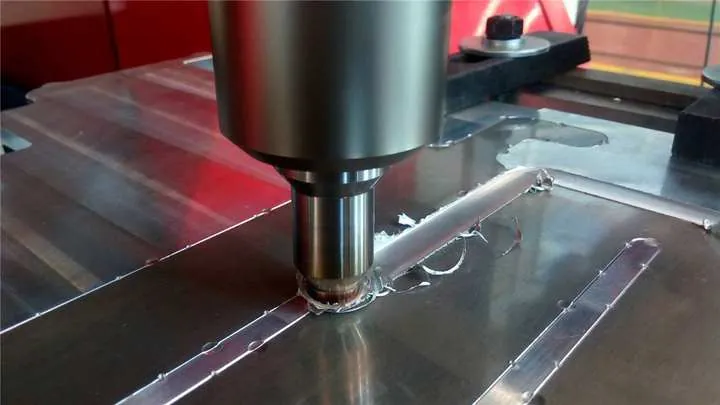

Stir-Welded Aluminum Components are precision-crafted parts that utilize friction stir welding to deliver durable, high-strength joints without melting-ideal for applications requiring structural reliability and performance consistency.

Constructed from high-grade aluminum alloys like 6063 and 7005, these components are subsequently refined through CNC machining to meet stringent dimensional and surface quality requirements.

By avoiding typical fusion-welding flaws and delivering enhanced joint integrity, this fabrication method ensures reliable performance under stress, vibration, and load cycling conditions.

The eco-conscious FSW process eliminates the need for filler materials and emits minimal emissions, while integrated machining and finishing streamline production for quality control and lead-time efficiency.

With full customization capabilities, advanced welding and machining integration, and secure packaging, our stir-welded aluminum components are ready for prompt deployment across global industrial applications.

Startform 200KG