Startform 200KG

Tilbud og estimering

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Hjem > Hul aluminiumsprofil Producent

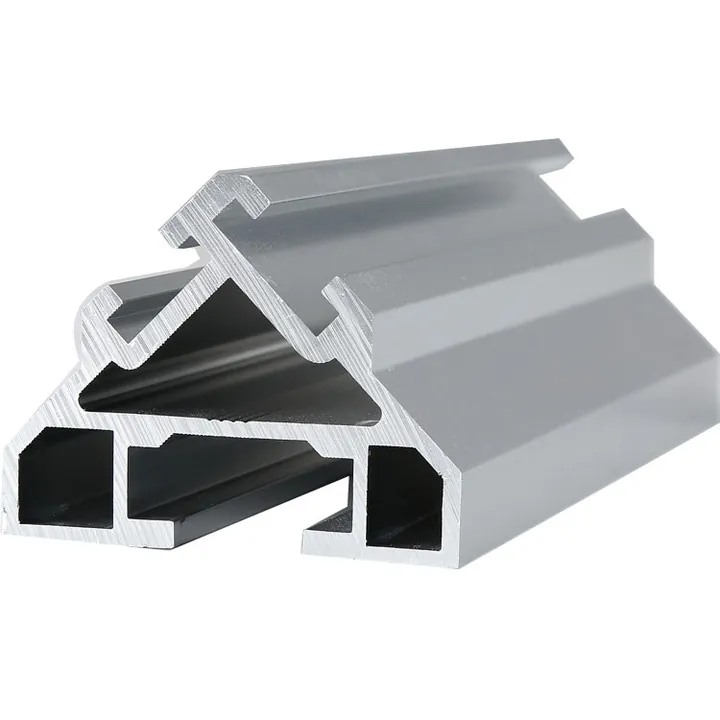

Our hollow aluminium profiles are engineered to your design needs-featuring customizable geometry, material selection, finishes, and ready for machining or assembly into functional components.

Produktion i stor skala:.Vores fabrik strækker sig over 1.000 mu (ca. 667.000 m²)med fuld in-house kapacitet fra aluminiumsmeltning og støbning af emner til ekstrudering, overfladebehandling og CNC-bearbejdning.

One-stop-løsning:.Med 43 ekstruderingslinjer (500-5500 tons) og en dedikeret skimmelpartner leverer vi hurtig produktion, tilpassede profiler og integrerede tjenester til forenkle din forsyningskæde.

Kvalitet, du kan stole på:.Streng kvalitetskontrol sikrer Ensartede dimensioner, styrke og finishDet reducerer din risiko og øger pålideligheden.

Hurtig levering og omkostningseffektivitet:.Egenproducerede billets, in-house forarbejdning og serieproduktion betyder hurtigere leveringstider og lavere samlede omkostninger.

Avancerede efterbehandlingsmuligheder:.Anodisering og både lodrette og vandrette pulverlakeringslinjer leverer holdbare overfladebehandlinger af høj kvalitet skræddersyet til dine produktbehov.

TRIN

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Oprettelse af en prototype for at vurdere dimensioner og sikre, at formens præcision stemmer overens med kravene.

Producerer aluminiumsprofilen med stor nøjagtighed i henhold til de givne specifikationer og anvender den ønskede finish.

Skræddersyet emballage til de ekstruderede profiler, der sikrer sikker og effektiv læsning til hurtig levering.

Hollow aluminium profiles combine lightweight design with structural integrity through strategically placed internal cavities. Their efficient one-piece extrusion simplifies assembly and enhances strength-to-weight performance.

Formed via split-die extrusion, these profiles deliver precision in geometry, wall thickness, and dimension-capable of being tailored to unique cross-section requirements.

Overfladebehandlinger som f.eks. anodisering, Pulverlakeringeller polering boost durability and visual appeal while safeguarding against corrosion.

Applicable across construction, industrial framing, automation, architectural, and transportation sectors, hollow profiles serve as versatile building blocks for modern engineering and design.

Made from sustainable aluminium, these profiles support eco-conscious manufacturing and benefit from low tooling costs, customizable options, and flexible production capabilities.

Startform 200KG