Startform 200KG

Tilbud og estimering

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Hjem > 7075 aluminiumsrør Producent

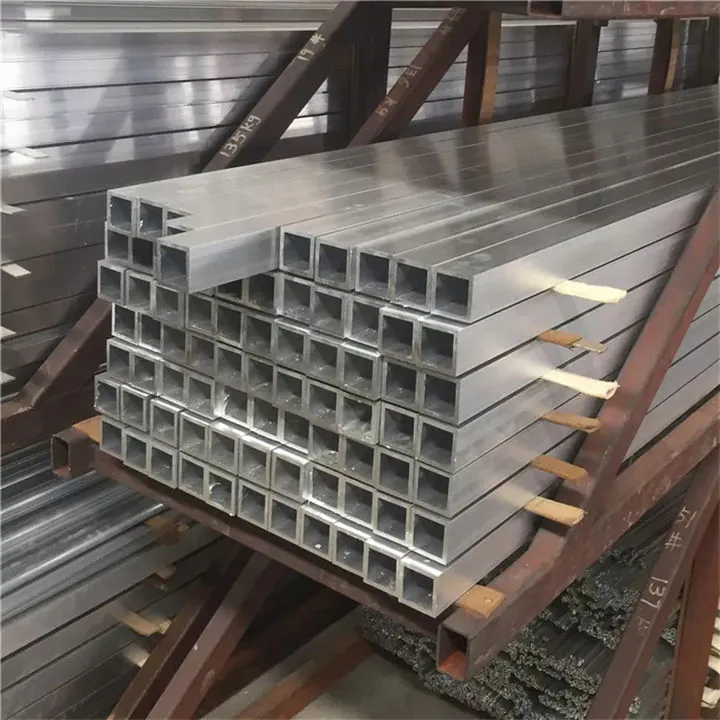

Our 7075 aluminum tubes are tailored to your project requirements, offering choice in form, temper, dimensions, and finish to best match performance and fabrication demands.

Produktion i stor skala:.Vores fabrik strækker sig over 1.000 mu (ca. 667.000 m²)med fuld in-house kapacitet fra aluminiumsmeltning og støbning af emner til ekstrudering, overfladebehandling og CNC-bearbejdning.

One-stop-løsning:.Med 43 ekstruderingslinjer (500-5500 tons) og en dedikeret skimmelpartner leverer vi hurtig produktion, tilpassede profiler og integrerede tjenester til forenkle din forsyningskæde.

Kvalitet, du kan stole på:.Streng kvalitetskontrol sikrer Ensartede dimensioner, styrke og finishDet reducerer din risiko og øger pålideligheden.

Hurtig levering og omkostningseffektivitet:.Egenproducerede billets, in-house forarbejdning og serieproduktion betyder hurtigere leveringstider og lavere samlede omkostninger.

Avancerede efterbehandlingsmuligheder:.Anodisering og både lodrette og vandrette pulverlakeringslinjer leverer holdbare overfladebehandlinger af høj kvalitet skræddersyet til dine produktbehov.

TRIN

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Oprettelse af en prototype for at vurdere dimensioner og sikre, at formens præcision stemmer overens med kravene.

Producerer aluminiumsprofilen med stor nøjagtighed i henhold til de givne specifikationer og anvender den ønskede finish.

Skræddersyet emballage til de ekstruderede profiler, der sikrer sikker og effektiv læsning til hurtig levering.

7075 aluminum tubes are engineered for applications demanding both high strength and low mass. With tensile strength comparable to steel and excellent fatigue resistance, they are ideal for aerospace, motorsports, and structural uses.

Available in multiple tempers-T6 and T651 for maximum strength, T73 or T7351 for enhanced stress corrosion resistance-these tubes can be extruded, drawn, seamless, or forged to suit your fabrication workflow.

Versatile surface finish options like anodisering, Pulverlakering, polishing or chemical passivation enable both functional enhancement and aesthetic customization.

From prototyping to mass production, our 7075 tubing service delivers precise dimensions, tight quality control, and secondary processing capabilities-such as CNC machining or laser cutting-for tailored integration into your product.

Compliant with key industry standards like ASTM and EN, our tubes combine performance, reliability, and manufacturability to meet the most demanding engineering requirements.

Startform 200KG