Hvordan polerer man aluminium?

Aluminum doesn’t shine on its own. It takes tools, polish, and a bit of effort to bring out its mirror-like surface.

To polish aluminum, you need to clean, sand, buff with compound, and then protect the surface. With the right steps, even dull or scratched aluminum can gleam.

Most people get stuck on where to start or what products to use. I’ll show you every step, including tools, techniques, and how to keep the shine lasting longer.

What Tools Are Needed to Polish Aluminum?

Polishing aluminum by hand is possible, but for large surfaces or deep oxidation, machines save time and give better results.

You’ll need a polishing tool (rotary or orbital), buffing pads (wool or foam), compounds, sandpaper, and safety gear like gloves and respirators.

Here’s a list of tools I always use:

| Værktøj | Formål |

|---|---|

| Rotary polisher | High-speed buffing for fast cutting |

| Dual-action polisher | Smooths out swirls and holograms |

| Wool pads | Aggressive cutting and oxidation removal |

| Foam pads | Final polishing and detailing |

| Sandpaper (400-2000 grit) | Scratch removal and surface prep |

| Metal polish cream | Adds final mirror finish |

| Microfiber towels | Clean-up and compound removal |

| Safety gear | Dust mask, goggles, gloves |

I’ve learned the hard way that cheap tools don’t last. I use a decent rotary polisher for cutting, followed by an orbital with foam pads to finish.

Using a dual-action polisher after rotary buffing helps remove swirl marks.Sandt

DA polishers create less heat and help finish the surface without holograms.

You can polish large aluminum panels quickly by hand only.Falsk

Machine tools significantly reduce time and improve finish quality.

What Polishes Work Best on Aluminum?

Polishing aluminum is like sanding wood-you move from coarse to fine until the shine comes through.

Use cutting compounds like Tripoli or gray bars to start, then switch to finer rouge or metal polishes for shine. Finish with a sealant to protect the result.

I’ve tested many products. Some work fast but leave haze, others polish well but take longer. Here’s a breakdown:

| Polish Type | Brugssag |

|---|---|

| Gray cutting compound | Removes oxidation and scratches |

| Tripoli | General-purpose aluminum cutting |

| White rouge | Finishing polish, mirror results |

| Diamond paste | Ultra-fine, great for small parts |

| All-purpose aluminum polish (like Mothers, Blue Magic) | Quick shine and oxidation removal |

| Cream polish (like Flitz) | Leaves protective layer |

My go-to combo:

- Tripoli with a wool pad

- White rouge with a foam pad

- Cream polish by hand

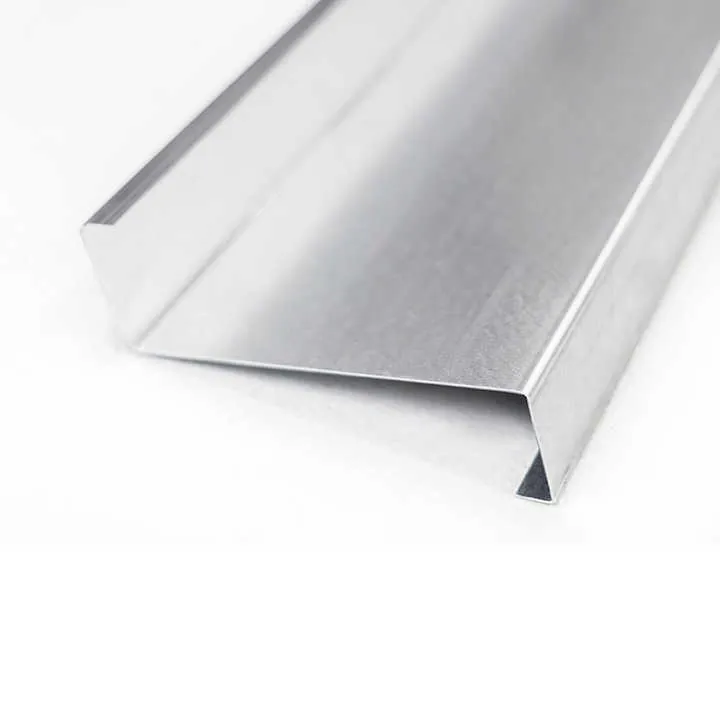

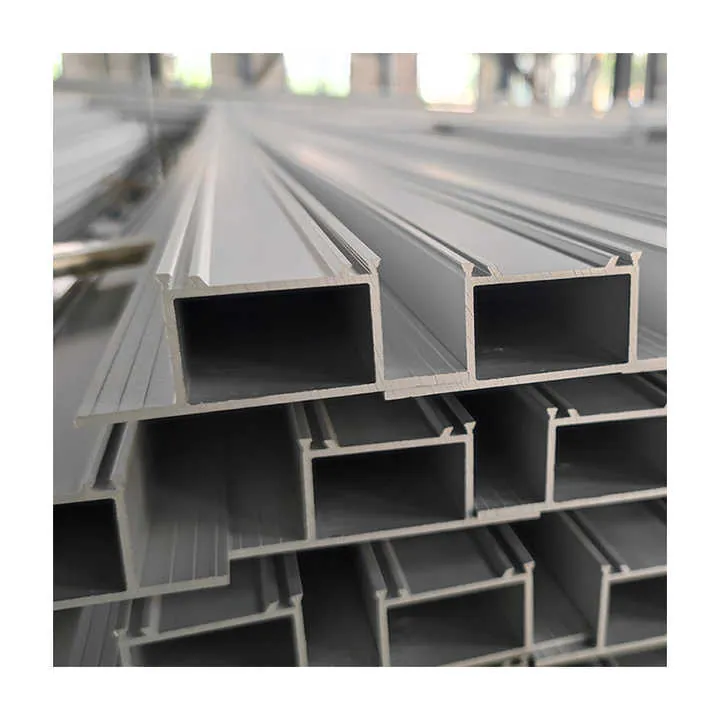

This gives deep shine on raw aluminum, wheels, or extruded profiles.

Tripoli and white rouge are commonly used for polishing aluminum to a mirror finish.Sandt

Tripoli cuts, and white rouge refines for shine.

You only need one polish type to complete aluminum polishing.Falsk

Multiple stages are needed for cutting, refining, and finishing.

How to Remove Scratches When Polishing Aluminum?

Even small scratches ruin the shine. Removing them is about sanding, cutting, and polishing in steps.

Start with sandpaper or coarse compound to remove surface scratches. Then use finer polishing stages until the metal becomes smooth and reflective.

Step-by-Step Scratch Removal:

- Clean the aluminum – Remove dirt, grease, or oils.

- Wet sand the surface – Start with 600 grit, move up to 2000.

- Use cutting compound – Tripoli or gray compound with wool pad.

- Polish with white rouge – Use foam pad for clarity.

- Hand buff with cream polish – Final step before sealing.

For deep gouges, you’ll need to start with 400 grit or even a file. But go slowly-you want to remove just enough to flatten the surface.

Use this grit chart as a guide:

| Sandpaper Grit | Brugssag |

|---|---|

| 400-600 | Deep scratches |

| 800-1000 | Mild surface prep |

| 1500-2000 | Pre-polish finish |

| 3000 | Ultra-fine polishing |

When polishing aluminum extrusions or parts with corners, I wrap sandpaper around a small block to keep pressure even.

Sanding aluminum before polishing helps remove scratches and levels the surface.Sandt

A smooth, even surface is essential for a consistent shine.

You should avoid sanding aluminum if it has scratches.Falsk

Sanding is necessary to remove surface defects before polishing.

How to Protect Aluminum After Polishing?

Bare aluminum starts to dull almost immediately. Exposure to air causes oxidation, especially in humid areas.

To keep aluminum polished, seal it with wax, ceramic coating, or a dedicated aluminum sealant. These create a barrier that slows oxidation.

My Top Protection Choices:

| Produkttype | Fordele | Ulemper |

|---|---|---|

| Carnauba wax | Easy to apply, short-term barrier | Wears off quickly |

| Ceramic coating | Long-lasting, weather-resistant | Prep is important |

| Aluminum sealant | Designed for raw metal | Needs reapplication |

| Clear coat spray | Durable, glossy finish | Can yellow over time |

I personally use a ceramic coating on high-use items like toolboxes, vehicle trim, and architectural aluminum profiles. For indoor decorative pieces, wax or polish with protectant is enough.

Here’s what I recommend based on use:

| Anvendelse | Beskyttelse |

|---|---|

| Auto parts | Ceramic or sealant |

| Tools / fixtures | Wax or polish |

| Outdoor panels | Clear coat or sealant |

| Interior décor | Cream polish |

Reapply as needed. Even sealed aluminum can show dullness after months if exposed to rain, sun, or salt.

Ceramic coatings offer long-term protection for polished aluminum.Sandt

They bond to the surface and resist moisture and oxidation.

Aluminum does not need any protection after polishing.Falsk

Without protection, polished aluminum oxidizes quickly and loses shine.

Konklusion

Polishing aluminum isn’t magic. It’s a process-clean, sand, cut, refine, and protect. The right tools and products make a big difference, and sealing the surface prevents oxidation from undoing your hard work.

From experience, the biggest mistake is skipping steps or trying to rush the finish. Take your time, work through each stage, and your aluminum will look better than new.

Jeg føler, at når jeg beslutter mig](https://sinoextrud.com/wp-content/uploads/auto_1756203839_1.webp 1024w, https://sinoextrud.com/wp-content/uploads/auto_1756203839_1-768x768.webp 768w, data:image/webp;base64,UklGRm4AAABXRUJQVlA4IGIAAAAQAgCdASoMAAwAAQAaJZwCw7ELT8mHaVAAAP71B+5k9/8OIH4ljai97rwcFQdPt63h/dFxP826lG4t8v06aMcrTG3tJJQwoTgUvWYyxDaPWA9hETv9WrDiFuqjrDA77AAAAA== 12w, https://sinoextrud.com/wp-content/uploads/auto_1756203839_1-600x600.webp 600w)