Aluminum extrusion environmental durability rating?

Environmental damage often appears slowly, then suddenly becomes expensive. Aluminum extrusions look stable at first, but climate, pollution, and moisture keep working every day. Many buyers realize durability problems only after installation.

The environmental durability rating of aluminum extrusions depends on testing methods, climate exposure, surface protection, and compliance with durability standards. Aluminum lasts long, but only when the right choices are made.

Once aluminum profiles leave the factory, the environment becomes the real test. Understanding durability ratings helps avoid hidden long-term risk.

What durability tests assess environmental exposure?

Environmental durability is not based on guesswork. It is measured through standardized tests that simulate long-term exposure.

Durability tests evaluate how aluminum extrusions resist corrosion, moisture, UV light, and temperature change over time.

Corrosion resistance testing

Corrosion is the main threat to aluminum in most environments. Tests expose samples to aggressive conditions.

Common corrosion tests include:

- Test med salttåge

- Acetic acid salt spray

- Cyclic corrosion testing

Salt spray testing is widely used to compare coatings and surface treatments. It does not predict exact service life, but it shows relative resistance.

Humidity and moisture testing

High humidity accelerates corrosion and coating failure.

Humidity tests check:

- Blistering

- Afskalning

- Loss of adhesion

Samples stay in hot, moist chambers for hundreds or thousands of hours.

UV and weathering tests

Outdoor aluminum faces sunlight every day. UV radiation breaks down coatings.

Weathering tests simulate:

- UV-eksponering

- Rain cycles

- Heat variation

These tests are critical for architectural and outdoor industrial profiles.

Temperature cycling tests

Temperature change causes expansion and contraction.

Thermal cycling tests reveal:

- Revner

- Coating separation

- Fælles stress

This matters in regions with hot days and cold nights.

Common durability tests overview

| Test type | Formål |

|---|---|

| Saltspray | Modstandsdygtighed over for korrosion |

| Humidity test | Moisture durability |

| UV weathering | Color and coating stability |

| Termisk cykling | Stress resistance |

Environmental durability of aluminum extrusions is evaluated through standardized laboratory tests.Sandt

Tests simulate corrosion, moisture, UV exposure, and temperature changes.

Visual inspection alone is enough to rate aluminum environmental durability.Falsk

Durability ratings rely on controlled testing, not appearance alone.

How do climate conditions affect extrusion lifespan?

Aluminum performs differently depending on where it is used. Climate is one of the strongest factors affecting lifespan.

Climate conditions such as humidity, temperature, pollution, and salt exposure directly influence how long aluminum extrusions last.

Marine and coastal environments

Coastal areas contain salt in the air. Salt accelerates corrosion.

In these regions:

- Bare aluminum corrodes faster

- Protective coatings are essential

- Regular cleaning improves lifespan

Without protection, surface pitting can appear early.

Industrial and urban environments

Cities and industrial zones expose aluminum to pollutants.

These include:

- Sulfur compounds

- Acid rain

- Dust particles

Pollution weakens protective oxide layers and coatings.

Hot and dry climates

High temperature alone does not damage aluminum quickly.

Men..:

- UV exposure affects coatings

- Sand abrasion damages surfaces

- Large temperature swings stress joints

Durability depends on surface protection quality.

Cold and freeze-thaw regions

Cold climates bring different risks.

Freeze-thaw cycles cause:

- Water expansion in gaps

- Coating cracking

- Tætningsfejl

Aluminum itself stays stable, but coatings and fasteners suffer.

Climate impact comparison

| Climate type | Main risk | Durability impact |

|---|---|---|

| Kystnære | Salt corrosion | Høj |

| Industriel | Kemisk eksponering | Middel til høj |

| Desert | UV and abrasion | Medium |

| Koldt | Termisk stress | Medium |

Climate conditions play a major role in aluminum extrusion lifespan.Sandt

Humidity, salt, pollution, and temperature affect corrosion and coating durability.

Aluminum extrusions perform the same in all climates.Falsk

Different climates create different environmental stresses.

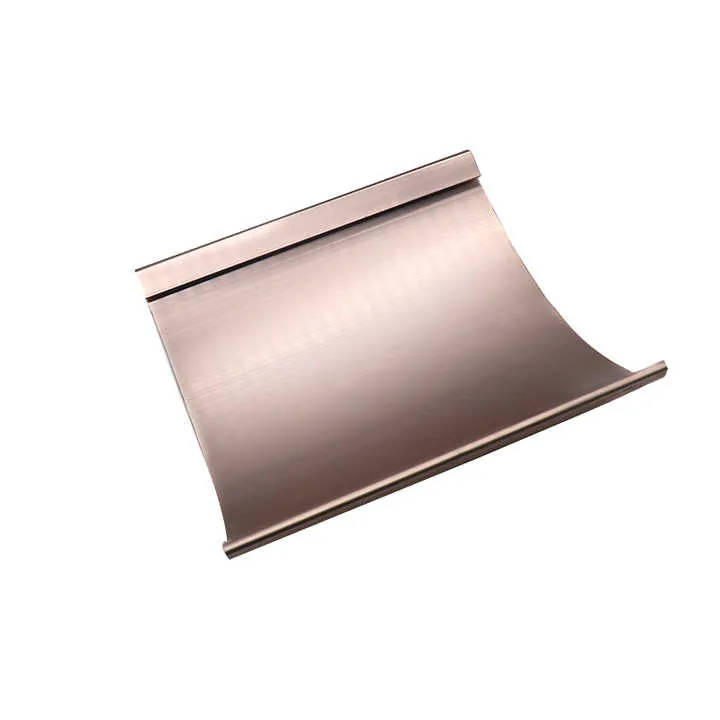

Can coatings extend environmental durability?

Surface protection is often the difference between short life and long service. Many buyers focus on alloy and forget coatings.

Coatings significantly extend the environmental durability of aluminum extrusions by protecting the surface from corrosion and weathering.

Purpose of aluminum coatings

Coatings act as barriers.

They:

- Block moisture

- Reduce chemical contact

- Slow oxidation

- Improve UV resistance

The right coating matches the environment.

Anodizing for durability

Anodizing thickens the natural oxide layer.

Fordelene omfatter:

- Høj korrosionsbestandighed

- No peeling

- Long-term stability

Thicker anodizing performs better outdoors, especially in polluted areas.

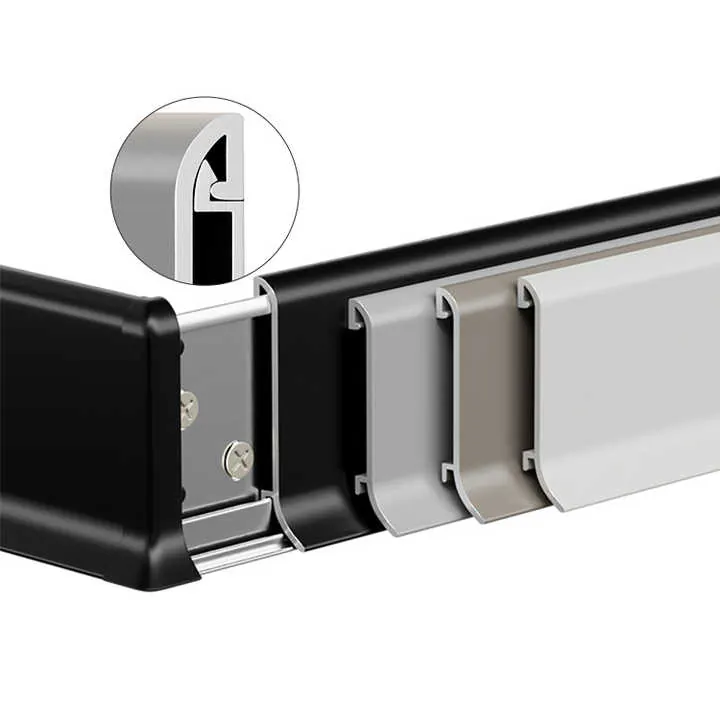

Powder coating protection

Powder coating adds a polymer layer.

Fordele:

- Strong color retention

- Good weather resistance

- Fleksibilitet i designet

Its durability depends on coating thickness and pretreatment quality.

PVDF coating for harsh environments

PVDF coatings are used for extreme exposure.

De tilbyder:

- Excellent UV resistance

- Strong chemical stability

- Lang levetid

They are common in high-end architectural projects.

Coating durability comparison

| Belægningstype | Udendørs holdbarhed | Behov for vedligeholdelse |

|---|---|---|

| Anodisering | Høj | Lav |

| Pulverlakering | Middel til høj | Medium |

| PVDF | Meget høj | Lav |

Maintenance still matters

Even coated aluminum needs care.

Simple actions help:

- Periodisk rengøring

- Avoid abrasive contact

- Inspect drainage areas

Coatings slow damage, but they do not stop time.

Proper coatings can greatly extend aluminum extrusion environmental durability.Sandt

Coatings protect aluminum from moisture, chemicals, and UV exposure.

Coatings make aluminum extrusions maintenance-free forever.Falsk

Coatings reduce damage but still require basic maintenance.

Which standards rate outdoor material durability?

Durability claims must be backed by standards. Without standards, ratings lose meaning.

Outdoor durability ratings are defined by international standards that specify testing methods and performance levels.

Common international standards

Different regions rely on different systems.

Widely used standards include:

- ISO-standarder

- ASTM-standarder

- EN-standarder

- AAMA specifications

These standards define how tests are run and how results are reported.

ISO durability standards

ISO standards focus on global consistency.

They cover:

- Corrosion testing

- Belægningens tykkelse

- Overfladebehandlingens kvalitet

ISO standards are widely accepted in international trade.

ASTM and AAMA standards

ASTM standards are common in North America.

They define:

- Salt spray duration

- Weathering exposure

- Performance benchmarks

AAMA standards focus on architectural aluminum and coatings.

EN standards in Europe

EN standards classify:

- Overfladebehandlingens kvalitet

- Environmental resistance

- Expected performance levels

They are often required for construction projects.

Standards selection by application

| Anvendelse | Typical standard |

|---|---|

| Arkitektur | EN, AAMA |

| Industriel | ISO, ASTM |

| Infrastruktur | ISO, EN |

| Export projects | ISO |

Importance of compliance

Standards help buyers:

- Sammenlign leverandører

- Verify durability claims

- Reduce project risk

Without standard compliance, durability ratings are unreliable.

Environmental durability ratings rely on recognized international standards.Sandt

Standards define testing methods and performance criteria.

There is one universal durability standard used worldwide.Falsk

Different regions use different standards depending on application.

Konklusion

Aluminum extrusion environmental durability depends on testing, climate, coatings, and standards. With proper evaluation and protection, aluminum profiles deliver long service life even in harsh outdoor environments.