Brandmodstandsklasse for ekstruderet aluminium?

Fire safety often becomes a problem only after a project is already designed. Aluminum profiles are light and strong, but many buyers worry about fire risk. This concern can slow decisions and raise doubts.

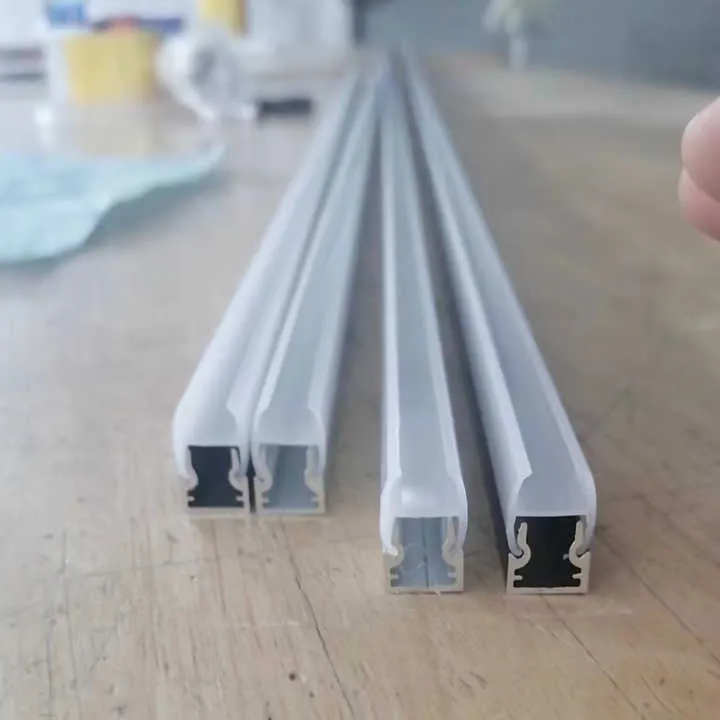

Aluminum extrusion itself does not burn, but its fire resistance rating depends on alloy, design, surface treatment, and system use. Aluminum melts at high temperature, so it must be evaluated as part of a complete fire-rated system.

Many buyers stop reading once they hear “aluminum melts.” That is a mistake. Fire performance is more complex, and understanding it can help make better design and sourcing choices.

What fire resistance ratings exist for aluminum structures?

Fire ratings are often confusing for aluminum buyers. Many people expect a simple number, but aluminum structures are not rated the same way as concrete or steel.

Aluminum structures usually do not have an intrinsic fire resistance rating. The rating applies to the full assembly, not the aluminum extrusion alone.

Aluminum behavior in fire

Aluminum is a non-combustible metal. It does not ignite or release toxic smoke. This is a strong advantage in fire scenarios. However, aluminum loses strength as temperature rises.

- Melting point is about 660C

- Strength drops sharply above 200C

- Shape stability depends on profile design

This means aluminum is safe from a burning point of view, but not from a load-bearing point of view in fire.

Fire resistance ratings explained

Fire resistance ratings are measured in time. Common values include 30, 60, 90, and 120 minutes. These numbers describe how long a structure can meet certain criteria during a standard fire test.

The test checks three main things:

- Bærende kapacitet

- Integrity against flame passage

- Insulation against heat transfer

Aluminum extrusions alone usually fail load-bearing criteria early. But when used inside systems, the result can change.

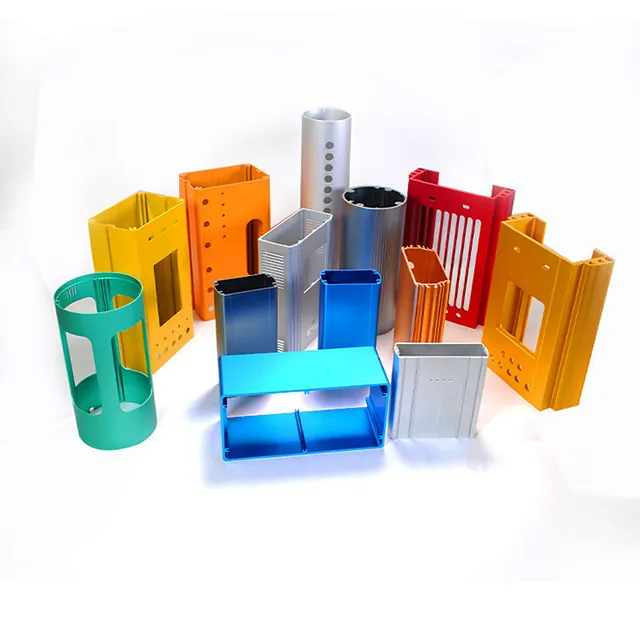

Typical aluminum applications and ratings

| Anvendelsesområde | Fire rating approach | Typical rating |

|---|---|---|

| Curtain wall frames | System tested with glass and seals | 30 to 60 min |

| Vinduesrammer | Often non-rated or limited rating | 0 to 30 min |

| Industrielle profiler | Depends on enclosure | System based |

| Skinner til montering af solceller | Usually non-rated | Not required |

In many projects, aluminum is allowed because it is not the main load-bearing element during fire.

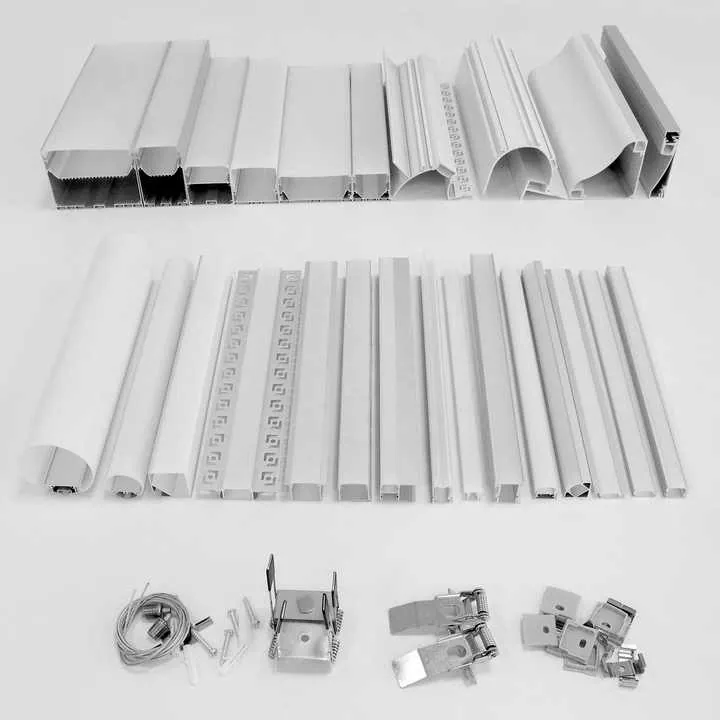

Design strategies to improve fire performance

Design has a big effect on fire results. Thick walls, closed sections, and thermal breaks can delay heat transfer.

Common methods include:

- Increasing wall thickness

- Adding fire-resistant boards

- Using intumescent coatings

- Designing aluminum as secondary structure

These methods do not change the aluminum itself. They change how the system reacts in fire.

Aluminum extrusions are non-combustible and do not contribute fuel to a fire.Sandt

Aluminum does not burn or ignite under normal fire conditions and is classified as non-combustible.

Aluminum profiles always have a 60-minute fire resistance rating by default.Falsk

Fire ratings apply to tested assemblies, not to aluminum extrusions by themselves.

How does surface treatment affect fire performance?

Surface treatment is often chosen for looks or corrosion resistance. Fire behavior is rarely discussed, but it matters in some cases.

Surface treatment does not change aluminum melting point, but it can affect smoke, flame spread, and surface reaction.

Common aluminum surface treatments

The most common treatments include:

- Anodisering

- Pulverlakering

- PVDF-belægning

- Elektroforese

- Mekanisk efterbehandling

Each treatment adds a thin layer to the aluminum surface.

Fire behavior of coatings

Coatings are organic or inorganic. This difference is critical in fire.

Organic coatings, like powder coating and PVDF, can:

- Burn or decompose

- Produce smoke

- Affect flame spread classification

Inorganic coatings, like anodizing, do not burn.

Flame spread and smoke development

Many fire codes focus on two indexes:

- Flame spread index

- Smoke development index

Surface coatings can raise both values.

| Overfladebehandling | Combustibility | Smoke risk | Fire impact |

|---|---|---|---|

| Anodisering | Ikke-brændbar | Meget lav | Minimal |

| Pulverlakering | Combustible | Medium | Moderat |

| PVDF-belægning | Combustible | Middel til høj | Højere |

| Elektroforese | Lav | Lav | Begrænset |

This is why some public projects restrict coated aluminum in escape routes.

Heat transfer and coating thickness

Coatings are thin. Typical thickness is:

- Anodizing: 10 to 25 microns

- Powder coating: 60 to 120 microns

These layers do not provide insulation. Heat passes through quickly. Fire resistance time does not increase.

Choosing surface treatment for fire-sensitive projects

For projects like:

- Metro stations

- Lufthavne

- Hospitaler

- High-rise stairwells

Anodized aluminum is often preferred. It meets non-combustible requirements more easily.

Anodizing does not add combustible material to aluminum surfaces.Sandt

Anodizing creates an oxide layer that is inorganic and non-combustible.

Powder coating improves aluminum fire resistance time.Falsk

Powder coating does not increase fire resistance time and may add combustible material.

Can anodized aluminum resist high temperatures?

Anodized aluminum is often seen as more fire safe. This is partly true, but it needs clear explanation.

Anodized aluminum resists surface damage at high temperature, but it still loses strength as the base aluminum heats up.

Hvad anodisering virkelig gør

Anodizing converts the aluminum surface into aluminum oxide. This layer is:

- Hård

- Stabil

- Ikke-brændbar

Aluminum oxide has a much higher melting point than aluminum metal.

Temperature resistance comparison

| Material layer | Approximate stability |

|---|---|

| Aluminum metal | Loses strength above 200C |

| Anodized oxide layer | Stable above 1000C |

| Pulverlakering | Degrades around 200-300C |

This means the surface remains intact longer, but the structure underneath still weakens.

Visual appearance in fire exposure

Anodized aluminum often:

- Changes color

- Shows surface dulling

- Keeps coating integrity

Powder-coated aluminum often:

- Bubbles

- Peels

- Produces smoke

This difference matters for post-fire inspection and safety evaluation.

Structural limits remain

Even with anodizing:

- Load capacity drops fast

- Deflection increases

- Connections may fail

Anodizing is not a fireproof solution. It is a safer surface option.

Practical use cases

Anodized aluminum is commonly used in:

- Fire escape handrails

- Facade sub-frames

- Interior public spaces

- Transportknudepunkter

It meets non-combustible surface rules but still relies on system design for fire rating.

Anodized aluminum maintains surface stability at very high temperatures.Sandt

The anodized oxide layer is stable at temperatures much higher than aluminum metal.

Anodizing allows aluminum to keep full structural strength in fire.Falsk

Anodizing does not prevent aluminum from losing strength as temperature rises.

Which regulations define fire rating requirements?

Fire rating rules depend on region and building type. Aluminum buyers must understand which standards apply before quoting or designing.

Fire rating requirements come from building codes and test standards, not from aluminum material specifications alone.

Main international fire standards

Different markets use different systems.

- Europe: EN standards

- United States: ASTM and NFPA

- Middle East: Civil defense codes

- Japan: Building Standard Law

Aluminum extrusions must fit into these frameworks.

European classification system

In Europe, reaction to fire is classified from A1 to F.

- A1: Non-combustible

- A2: Limited contribution

- B to F: Increasing fire risk

Bare aluminum and anodized aluminum usually meet A1 or A2. Coated aluminum may fall into lower classes unless tested.

Fire resistance versus reaction to fire

These are different concepts.

Reaction to fire:

- How material contributes to fire

- Flame spread

- Smoke

Fire resistance:

- How long an assembly resists fire

- Measured in minutes

Aluminum often passes reaction to fire but fails fire resistance alone.

Common regulatory expectations

| Building type | Typical requirement |

|---|---|

| Boliger | Limited fire resistance |

| Kommerciel | 30 to 60 min systems |

| High-rise | Strict system testing |

| Industriel | Case specific |

This is why aluminum is widely used but rarely alone in fire-rated elements.

Buyer responsibility in compliance

Manufacturers supply profiles. Designers define systems. Contractors install assemblies.

Buyers should:

- Ask for fire test reports

- Confirm surface treatment class

- Match product use to code

This avoids risk at inspection stage.

Fire resistance requirements are defined by building codes and tested assemblies.Sandt

Codes and standards define how systems must perform in fire, not individual materials alone.

All aluminum extrusions automatically meet global fire rating rules.Falsk

Compliance depends on application, surface treatment, and tested system design.

Konklusion

Aluminum extrusions are safe, non-combustible, and widely accepted in construction. Fire resistance ratings depend on system design, surface treatment, and regulation. Understanding these limits helps buyers choose aluminum with confidence.