CNC-bearbejdning Zimbabwe: Producent- og industriguide

Del 1: Markedets størrelse og vækst

Zimbabwe’s manufacturing and engineering sector has been undergoing a slow but determined transformation. Despite decades of economic turbulence, CNC-bearbejdning is becoming increasingly important as the country’s industries aim to modernize and rebuild local production capacity. In Harare, Bulawayo, and other industrial centers, small workshops are transitioning from manual machining to computer-controlled systems to improve precision and reduce waste.

The growing sectors driving demand for CNC machining include mining, agriculture, automotive repair, and construction. Zimbabwe’s large mining industry, which produces gold, platinum, and chrome, depends heavily on reliable repair and maintenance services. Machining workshops provide spare parts for pumps, shafts, crushers, and transport systems. With import costs rising, local manufacturing and precision machining are now more valuable than ever.

Although the market is still small, it shows potential for growth. The government’s focus on “local content” and import substitution policies encourages investment in local mechanical production. Workshops capable of offering CNC machining can secure contracts from both state-owned enterprises and private industrial clients seeking faster turnaround and better control over quality.

Challenges persist, however. Access to modern machinery and cutting tools is limited by high import costs, inconsistent power supply, and limited training. Yet, the combination of resourceful engineering talent and growing demand for quality parts has laid a foundation for Zimbabwe’s next phase of industrial development.

Del 2: Ledende virksomheder

Below are representative examples of CNC machining and precision engineering firms operating in Zimbabwe. These companies demonstrate how the sector is diversifying and adopting advanced technologies despite economic constraints.

Precision Grinders Engineers (Harare)

Kontakt nu

Precision Grinders Engineers is one of Zimbabwe’s most established engineering firms. It provides CNC machining, fabrication, and mechanical repairs from its large Harare facility.

Founded decades ago, the company supports industries including mining, agriculture, and manufacturing. It operates CNC lathes and milling centers alongside conventional machines. Precision Grinders Engineers is known for its focus on precision, reliability, and local innovation. Their technicians design and produce components such as drive shafts, pulleys, gears, and custom tooling for industrial clients. The company’s long-standing presence and reputation for excellence make it a cornerstone of Zimbabwe’s mechanical engineering sector.

BSI Steel Engineering Division

Kontakt nu

BSI Steel’s Zimbabwe branch, while primarily a steel supplier, operates an engineering division with CNC cutting and fabrication capabilities.

They provide sheet metal cutting, drilling, bending, and machining services for customers requiring metal structures and industrial components. Their CNC plasma and laser cutting lines are used for manufacturing machinery frames, construction elements, and custom assemblies. The company combines imported steel with in-house fabrication to serve mining, manufacturing, and construction industries.

Fitment Centre Engineering (Bulawayo)

Kontakt nu

Fitment Centre Engineering is a Bulawayo-based machine and auto-engineering workshop offering CNC turning and general machining services.

They serve clients in transport, agricultural machinery, and equipment repair. The workshop provides crankshaft reconditioning, hydraulic component machining, and precision turning of custom parts. Their competitive edge lies in speed and adaptability-many of their customers require fast repair and part replacement for field machinery. By integrating CNC machines into their operations, Fitment Centre has improved accuracy and repeatability while reducing lead times.

Hydramatics Engineering

Kontakt nu

Hydramatics Engineering specializes in hydraulic system repair, precision machining, and cylinder refurbishment.

Their workshop, located in Harare’s industrial area, offers turning, honing, milling, and component fabrication. Hydramatics supports mining, agricultural, and construction clients that rely on hydraulic cylinders and pumps. Their CNC upgrades allow tighter tolerances and higher durability in replacement parts. Their combination of hydraulic expertise and precision machining makes them a vital partner for many industries.

Bulawayo Metalworks

Kontakt nu

Bulawayo Metalworks is a general engineering firm that focuses on CNC milling, fabrication, and repair of industrial and agricultural equipment.

They handle gear cutting, keyway milling, and small batch production of custom parts. The workshop also provides mobile services for on-site machining. Bulawayo Metalworks stands out for its flexibility and strong client relationships, serving customers in mining, logistics, and processing industries across southern Zimbabwe.

| Virksomhed | Grundlagt | Kerneydelser | Industrier, der betjenes | Styrker |

|---|---|---|---|---|

| Precision Grinders Engineers | 1940s | CNC machining, fabrication, repair | Mining, agriculture, industrial | Long experience, precision reputation |

| BSI Steel Engineering Division | 2000s | CNC cutting, drilling, fabrication | Construction, manufacturing | Integrated supply chain, modern equipment |

| Fitment Centre Engineering | 2010s | CNC turning, repair, reconditioning | Transport, machinery repair | Fast service, local adaptability |

| Hydramatics Engineering | 2000s | Hydraulic repair, honing, machining | Mining, construction | Precision in hydraulic parts |

| Bulawayo Metalworks | 2010s | CNC milling, gear cutting, fabrication | Mining, agriculture | Mobility, client customization |

Del 3: Messer og brancheevents

Zimbabwe International Trade Fair (ZITF)

The Zimbabwe International Trade Fair, held annually in Bulawayo, is the country’s premier industrial exhibition.

It showcases manufacturing, engineering, mining, and agricultural technology. CNC machining companies and suppliers attend to promote precision services, display sample parts, and meet clients across southern Africa. ZITF is also an opportunity for local workshops to learn about new tools, materials, and digital production trends.

Mine Entra Exhibition

Mine Entra is Zimbabwe’s key mining, engineering, and transport exhibition held annually in Bulawayo.

For CNC machining firms, it provides access to major mining corporations and service contractors. Exhibitors include machine tool suppliers, maintenance companies, and industrial solution providers. The event fosters partnerships that help workshops expand capacity and upgrade equipment.

| Begivenhed | Frekvens | Beliggenhed | Højdepunkter |

|---|---|---|---|

| Zimbabwe International Trade Fair (ZITF) | Årligt | Bulawayo | Manufacturing, precision tools, partnerships |

| Mine Entra | Årligt | Bulawayo | Mining tech, CNC services, machinery repair |

Del 4: Indvirkning af globale handelspolitikker

Zimbabwe’s CNC machining industry is heavily influenced by import policy, exchange rate fluctuations, and global supply chains.

Most CNC machines, cutting tools, and spare parts are imported from South Africa, China, and Europe. High shipping costs and customs procedures make procurement slow and expensive. Currency instability also affects spare part pricing and maintenance budgets, pushing workshops to rely on refurbished machines or locally fabricated tooling.

However, trade relationships with neighboring countries in the Southern African Development Community (SADC) create opportunities. Duty reductions and easier border procedures within SADC allow workshops to source materials and equipment more efficiently. Regional suppliers provide cutting inserts, lubricants, and machine components that keep Zimbabwe’s CNC shops operational.

Infrastructure challenges-such as power reliability and fuel availability-still hinder full-scale modernization. CNC machines are sensitive to power fluctuations, so many workshops invest in backup power systems. Improvements in energy supply could significantly enhance the efficiency and competitiveness of local machining firms.

To encourage industrialization, the government has introduced initiatives to attract investment in local manufacturing, repair industries, and technical training. If supported by tax incentives and easier access to imported technology, Zimbabwe’s CNC machining capacity could grow rapidly.

In addition, collaboration between private workshops and vocational institutions is expanding. Technical schools in Harare and Bulawayo have started integrating CNC programming and machine tool maintenance courses. Building a skilled workforce is essential for sustaining growth in the machining sector.

Del 5: Konklusion

CNC machining in Zimbabwe reflects a story of resilience and innovation. Despite limited resources, local workshops have adapted to economic challenges and continued serving the country’s essential industries. Companies like Precision Grinders Engineers, Hydramatics Engineeringog BSI Steel Engineering Division demonstrate how modern machining can thrive alongside traditional craftsmanship.

The future of CNC machining in Zimbabwe will depend on investment in technology, skills, and infrastructure. Access to affordable tooling, reliable electricity, and consistent trade policy will determine how quickly the industry can scale. Workshops that adopt automation, digital design, and quality control standards will find themselves well positioned to serve both domestic and regional clients.

In the coming decade, as industrial policies evolve and technology becomes more accessible, Zimbabwe’s CNC machining sector may transition from local service work to regional export manufacturing. The combination of engineering heritage, skilled labor, and growing demand makes this transformation not just possible, but increasingly inevitable.

With precision at its heart, CNC machining will continue to support Zimbabwe’s mining, agriculture, and construction sectors-building a foundation for a modern, self-reliant industrial economy.

Anbefalet læsning:.

- CNC Machining Georgia: Manufacturers & Industry Guide

- CNC Machining Malta: Manufacturers & Industry Guide

- CNC Machining Cape Verde: Manufacturers & Industry Guide

- CNC Machining Suriname: Manufacturers & Industry Guide

- CNC Machining Myanmar: Manufacturers & Industry Guide

- CNC Machining Mali: Manufacturers & Industry Guide

- CNC Machining Equatorial Guinea: Manufacturers & Industry Guide

- CNC Machining Guinea-Bissau: Manufacturers & Industry Guide

Varmebehandling af aluminiumslegering?

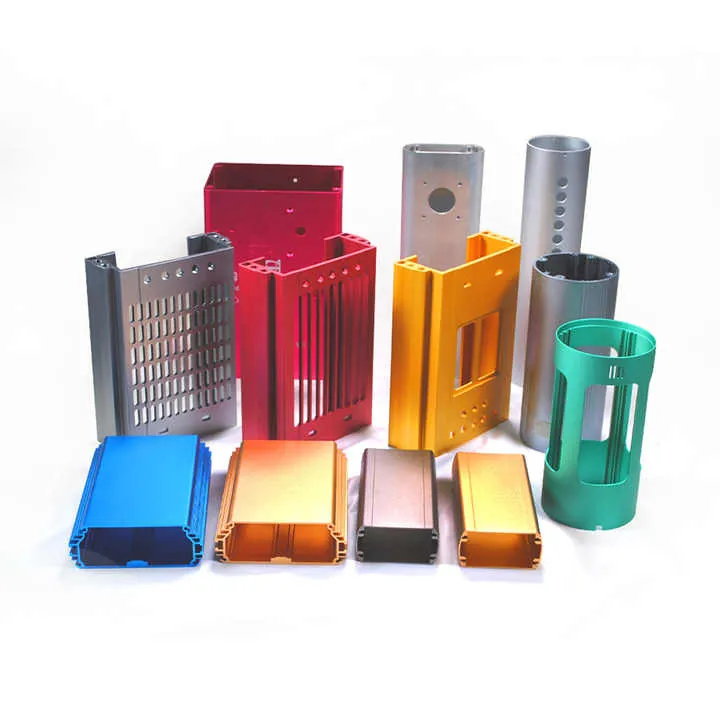

Lameller af ekstruderet aluminium

Bilpedal i aluminium Anodiseret sølv

Ekstruderede aluminiumsprofiler priser konkurrencedygtige 99% ren aluminiumsbarre gardinvæg aluminiumsprofil ekstrudering producenter