Startform 200KG

Tilbud og estimering

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

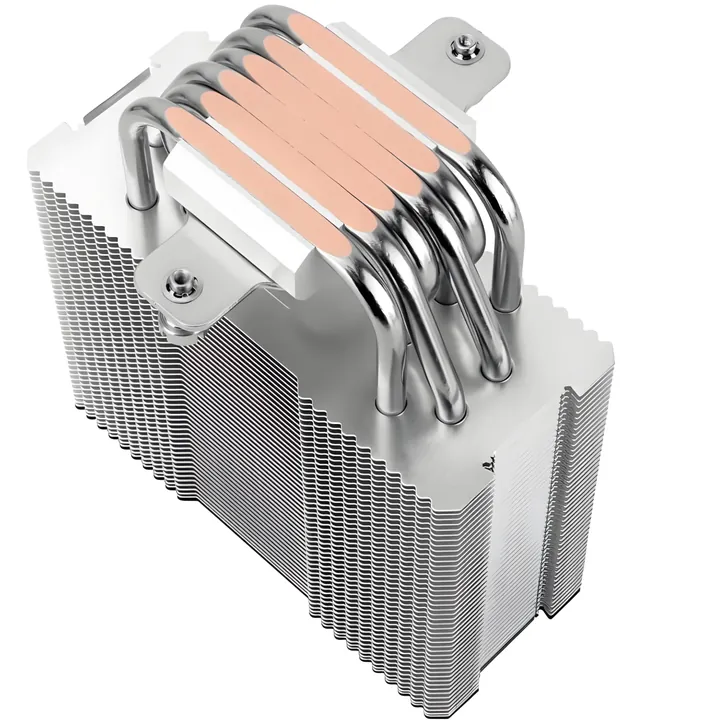

Hjem > Ekstruderet køleplade med dampkammer Producent

Vores ekstruderede køleplader med dampkammer er konstrueret til at kombinere hurtig tofaset varmespredning med effektiv finnebaseret konvektion. De kan tilpasses fuldt ud med hensyn til materiale, form, limningsmetode og overfladefinish og er optimeret til termisk styring af mellemstor effekt.

Produktion i stor skala:.Vores fabrik strækker sig over 1.000 mu (ca. 667.000 m²)med fuld in-house kapacitet fra aluminiumsmeltning og støbning af emner til ekstrudering, overfladebehandling og CNC-bearbejdning.

One-stop-løsning:.Med 43 ekstruderingslinjer (500-5500 tons) og en dedikeret skimmelpartner leverer vi hurtig produktion, tilpassede profiler og integrerede tjenester til forenkle din forsyningskæde.

Kvalitet, du kan stole på:.Streng kvalitetskontrol sikrer Ensartede dimensioner, styrke og finishDet reducerer din risiko og øger pålideligheden.

Hurtig levering og omkostningseffektivitet:.Egenproducerede billets, in-house forarbejdning og serieproduktion betyder hurtigere leveringstider og lavere samlede omkostninger.

Avancerede efterbehandlingsmuligheder:.Anodisering og både lodrette og vandrette pulverlakeringslinjer leverer holdbare overfladebehandlinger af høj kvalitet skræddersyet til dine produktbehov.

TRIN

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Oprettelse af en prototype for at vurdere dimensioner og sikre, at formens præcision stemmer overens med kravene.

Producerer aluminiumsprofilen med stor nøjagtighed i henhold til de givne specifikationer og anvender den ønskede finish.

Skræddersyet emballage til de ekstruderede profiler, der sikrer sikker og effektiv læsning til hurtig levering.

Ekstruderede køleplader med dampkammer er en innovativ termisk løsning, der integrerer fordelene ved tofaset dampkammerkøling med traditionel aluminiumsekstrudering. Dette design giver mulighed for effektiv varmespredning og -afledning i en slank, modulær struktur.

De er ideelle til kompakte elektroniske systemer såsom kommunikationsenheder, LED-drivere, indlejrede moduler og miniaturiserede strømkomponenter, hvor pladsbesparelse og pålidelig køling er afgørende.

Aluminiumsekstruderingsprocessen muliggør en alsidig finnegeometri for at øge overfladearealet, mens dampkammerbasen hurtigt spreder lokaliseret varme til finnerne. Tilsammen resulterer det i lavere komponenttemperaturer og forbedret systempålidelighed.

Vores ekstruderede vaske med dampkammer fås i flere konfigurationer og overflader med Støtte til CNC-bearbejdning, limning og termisk design leveres for at sikre nem integration i din produktlinje.

Uanset om det drejer sig om industrielle systemer med høj densitet eller næste generations forbrugerelektronik, leverer vores kølelegemeløsninger stabil, lydløs og omkostningseffektiv termisk ydeevne.

Startform 200KG