Startform 200KG

Tilbud og estimering

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Hjem > Dampkammer faseændring køleplade Producent

Specialfremstillede aluminiums-dampkammerkøleplader designet til effektiv, lavprofil termisk styring i avanceret elektronik. Vi tilbyder fuld fleksibilitet i design og forarbejdning – fra kernekammerstruktur til finintegration og overfladebehandling – der opfylder præcise termiske og mekaniske krav.

Produktion i stor skala:.Vores fabrik strækker sig over 1.000 mu (ca. 667.000 m²)med fuld in-house kapacitet fra aluminiumsmeltning og støbning af emner til ekstrudering, overfladebehandling og CNC-bearbejdning.

One-stop-løsning:.Med 43 ekstruderingslinjer (500-5500 tons) og en dedikeret skimmelpartner leverer vi hurtig produktion, tilpassede profiler og integrerede tjenester til forenkle din forsyningskæde.

Kvalitet, du kan stole på:.Streng kvalitetskontrol sikrer Ensartede dimensioner, styrke og finishDet reducerer din risiko og øger pålideligheden.

Hurtig levering og omkostningseffektivitet:.Egenproducerede billets, in-house forarbejdning og serieproduktion betyder hurtigere leveringstider og lavere samlede omkostninger.

Avancerede efterbehandlingsmuligheder:.Anodisering og både lodrette og vandrette pulverlakeringslinjer leverer holdbare overfladebehandlinger af høj kvalitet skræddersyet til dine produktbehov.

TRIN

Begynd med en grundig evaluering af designets gennemførlighed, efterfulgt af et hurtigt, detaljeret overslag.

Oprettelse af en prototype for at vurdere dimensioner og sikre, at formens præcision stemmer overens med kravene.

Producerer aluminiumsprofilen med stor nøjagtighed i henhold til de givne specifikationer og anvender den ønskede finish.

Skræddersyet emballage til de ekstruderede profiler, der sikrer sikker og effektiv læsning til hurtig levering.

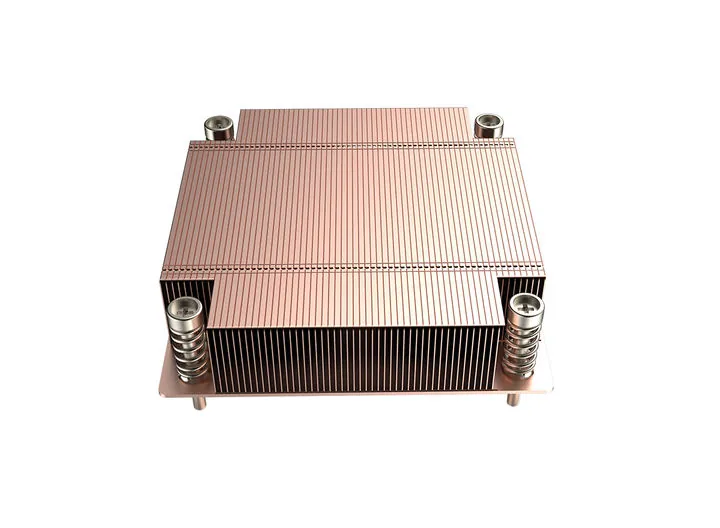

Dampkammer-faseændringskøleplader bruger et forseglet kammer, der udnytter overgangen fra væske til damp til hurtigt at overføre varme på tværs af basen, hvilket giver enestående varmeledningsevne og ensartet temperaturstyring.

Disse avancerede kølelegemer har en tynd, lavprofilstruktur ideel til applikationer med begrænset plads, da den er let, men alligevel robust og leverer høj ydeevne i elektronik med høj densitet, datacentermoduler, GPU-systemer og telekommunikationsudstyr.

Konstrueret af aluminiumslegering Med præcisionsstrækning og efterbehandlingsmuligheder – fræset finish, anodisering, pulverlakering i flere farver – balancerer de holdbarhed, korrosionsbestandighed og designkompatibilitet.

Vores produktion understøtter komplekse dyb bearbejdning funktioner, herunder bøjning, svejsning, stansning, afrulning og skæring, hvilket muliggør problemfri integration i slutbrugssamlinger.

Med skalerbar produktion, responsiv teknisk support og stor fleksibilitet i tilpasningen er vi den optimale leverandør af faseændringsmoduler til krævende B2B-applikationer.

Startform 200KG