Porovnání mezí kluzu hliníkových výlisků?

Many buyers compare aluminum profiles only by size and price. Later, frames bend or deform. This creates safety risk and rework cost. The real issue often hides in yield strength.

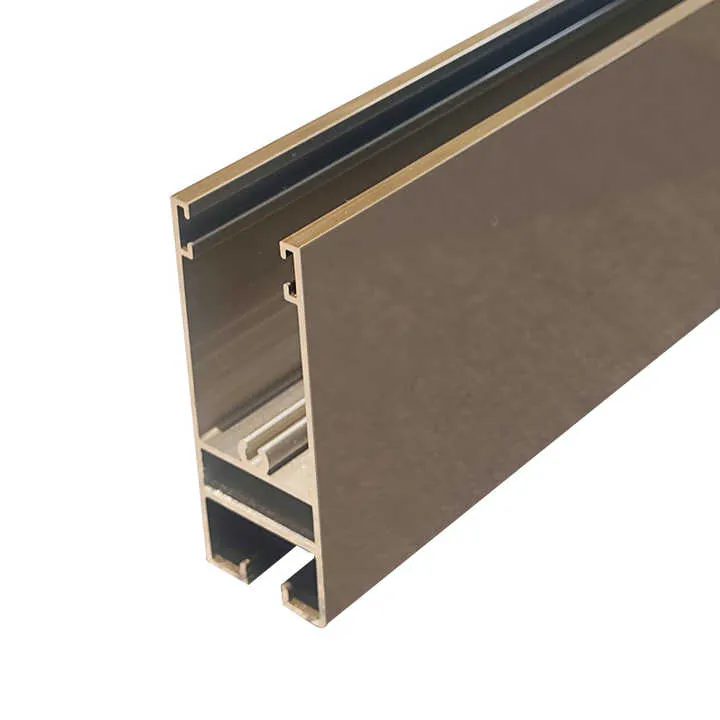

Aluminum extrusion yield strength varies widely based on alloy, heat treatment, process control, and testing standard. Understanding these differences is critical for correct material selection.

Yield strength is the point where aluminum stops returning to its original shape. Once passed, damage is permanent. This article breaks yield strength into clear parts so decisions stay practical and safe.

Which aluminum alloys offer the highest yield strength?

Many catalogs list alloy numbers without context. This leads buyers to assume all aluminum behaves the same. That assumption causes frame failure under real load.

High strength aluminum alloys like 6061-T6 and 6082-T6 offer much higher yield strength than decorative or architectural grades such as 6063-T5.

Yield strength depends on alloy chemistry. Elements like magnesium and silicon play a major role.

Common extrusion alloys and yield strength range

Below is a simplified comparison often used during early design review.

| Slitina a tvrdost | Typical yield strength MPa | Typical application |

|---|---|---|

| 6063-T5 | 110-140 | Architektonické, lehké rámy |

| 6063-T6 | 160-190 | Medium duty frames |

| 6061-T6 | 240-275 | Rámy pro vysoké zatížení |

| 6082-T6 | 250-300 | Structural and load bearing |

These values vary by supplier and process. They are reference ranges, not guarantees.

Why higher yield strength matters

Higher yield strength allows smaller profiles to carry the same load. This reduces weight and sometimes cost. It also increases safety margin before permanent deformation.

Alloy selection mistake seen often

Some buyers select 6063 for heavy frames because of good surface finish. Later, the frame bends under load. Surface quality does not equal mechanical strength.

Strength is not the only factor

High yield strength alloys can be harder to extrude. They may cost more and limit complex shapes. The right choice balances strength, shape, and budget.

Praktické pokyny

For load bearing industrial frames, 6061-T6 or 6082-T6 is usually the safer baseline. Lower strength alloys fit non structural or decorative use.

6061-T6 aluminum generally offers higher yield strength than 6063-T5.Pravda

6061-T6 contains alloying elements and heat treatment that produce much higher yield strength than 6063-T5.

All aluminum extrusion alloys provide similar yield strength when profile size increases.False

Increasing size does not change the material yield strength, which is controlled by alloy and temper.

How does heat treatment influence yield results?

Some buyers see T5 and T6 as minor labels. In reality, heat treatment can double yield strength. Ignoring this step leads to underperforming frames.

Heat treatment controls the internal structure of aluminum and has a direct and significant impact on yield strength.

Extruded aluminum leaves the press hot. What happens next defines its final strength.

Basic heat treatment steps

Heat treatment usually includes solution heating, quenching, and aging. Each step locks alloying elements into a stronger structure.

T5 vs T6 explained simply

T5 means cooled from extrusion temperature and artificially aged. T6 means solution heat treated and then aged. T6 usually produces higher yield strength.

Yield strength improvement example

6063 in T5 condition may reach around 120 MPa. The same alloy in T6 condition can reach near 180 MPa. That difference can decide success or failure.

Why some profiles cannot reach T6

Thick or complex profiles cool unevenly. This limits proper heat treatment. Large sections may not achieve full T6 strength across the whole profile.

Aging time matters

Under aging produces low yield strength. Over aging reduces strength again. Process control is critical. Poor aging control causes batch inconsistency.

Real production risk

I have seen mixed T5 and T6 profiles delivered in the same project. The frames looked identical but behaved very differently under load.

Buyer action point

Always confirm temper and request mechanical test reports. Do not assume heat treatment based on appearance.

Heat treatment can significantly increase the yield strength of aluminum extrusions.Pravda

Proper solution heat treatment and aging refine the structure and raise yield strength.

T5 and T6 tempers provide the same yield strength for aluminum extrusions.False

T6 temper usually delivers much higher yield strength than T5.

Can extruded profiles maintain consistent yield strength?

Consistency matters as much as peak strength. One weak profile can compromise an entire frame system.

Consistent yield strength is achievable, but only with strict control of billet quality, extrusion process, and heat treatment.

Yield variation often comes from upstream factors buyers never see.

Billet quality impact

Different billet suppliers produce different chemistry tolerance. Small changes affect final yield strength. Reliable mills control billet sourcing tightly.

Rychlost a teplota vytlačování

High speed reduces cost but may lower strength. Uneven temperature causes local soft zones inside the profile.

Kolísání tloušťky stěny

Thin and thick areas cool at different rates. This creates uneven aging response. Uniform wall design improves consistency.

Length wise variation

Front and tail of extrusion runs may show different properties. Proper cutting and testing reduce risk.

Quality control practices that matter

Consistent producers test each batch. They track yield strength trends. Poor producers rely only on design values.

What buyers should request

Ask for batch test reports and temper verification. For critical frames, request third party testing.

Field lesson learned

In one factory project, inconsistent yield strength caused random deformation during installation. Replacing profiles cost more than the original savings.

Consistent yield strength requires control of billet quality and extrusion parameters.Pravda

Yield consistency depends on material chemistry, extrusion temperature, and heat treatment control.

Yield strength variation has no impact on frame safety if average values meet requirements.False

Local weak zones can fail even if average yield strength appears acceptable.

What standards define yield strength benchmarks?

Numbers without standards are meaningless. Yield strength must be defined and tested using accepted rules.

International standards specify how yield strength is measured, reported, and compared for aluminum extrusions.

Standards protect buyers from inflated claims.

Common standards used globally

| Standardní | Region | Účel |

|---|---|---|

| ASTM B221 | Severní Amerika | Extruded aluminum mechanical properties |

| EN 755 | Evropa | Aluminum extrusion requirements |

| GB T 5237 | Čína | Aluminum profile specification |

| ISO 6362 | Globální | Wrought aluminum properties |

Each standard defines test method, sample location, and acceptance criteria.

Yield definition matters

Some standards use 0.2 percent offset yield strength. Others may report proof stress. Mixing these creates confusion.

Why benchmark comparison fails

Comparing ASTM values with EN values without conversion leads to wrong conclusions. Always confirm test method.

Certification is not optional

Mill certificates prove compliance. Without them, yield numbers are only claims.

Practical buyer checklist

Confirm standard, temper, test method, and batch number. This avoids disputes and quality risk.

Yield strength must be defined using recognized testing standards.Pravda

Standards ensure consistent measurement and fair comparison.

Yield strength values can be freely compared across standards without clarification.False

Different standards and test methods can produce different reported values.

Závěr

Yield strength comparison only works when alloy, heat treatment, consistency, and standards are understood together. Clear definitions and verified data protect frames from silent failure and long term risk.