Hliníkový výlisek vhodný pro letecké komponenty?

Aluminum parts in aircraft face extreme demands: weight limits, strength needs, and safety regulations. Choosing the wrong material risks failure.

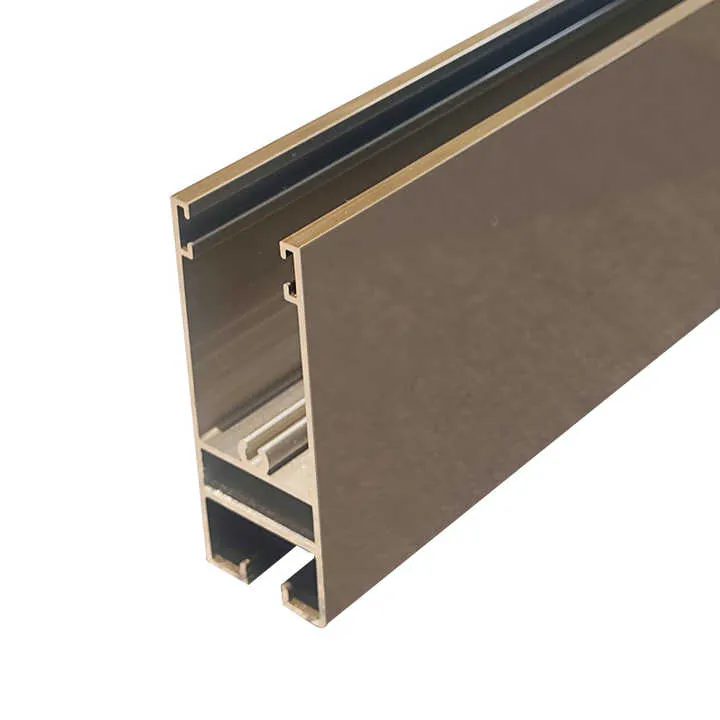

Aluminum extrusions are used in aerospace because they combine light weight, strength, corrosion resistance, and design flexibility in a cost-effective form.

This article explores why aluminum extrusion is trusted in aerospace, what certifications are required, how it performs in vibration, and whether profiles are customized for aircraft types.

Why is aluminum extrusion used in aerospace parts?

Aircraft need components that are light, strong, and consistent. Extruded aluminum meets all three demands in one package.

Aluminum extrusions offer high strength-to-weight ratio, formability, and fatigue resistance—ideal for structural aircraft parts.

Aluminum is naturally corrosion-resistant and easy to machine or coat. When extruded, it can be shaped into precise cross-sections that reduce welding and simplify assembly.

Advantages of aluminum extrusions in aerospace

| Funkce | Benefit in Aerospace Use |

|---|---|

| Low density | Reduces aircraft weight and improves fuel efficiency |

| Strong alloys (6061, 7075) | High strength for structural integrity |

| Odolnost proti korozi | Withstands moisture, salt, and chemicals |

| Vlastní návrh profilu | Tailors parts to specific load or space constraints |

| Recyclable material | Supports sustainability goals |

Extrusions also allow hidden reinforcements, hollow structures, and multi-function profiles—all without extra joints or welds.

Aluminum extrusions help reduce aircraft weight while maintaining structural strength.Pravda

The high strength-to-weight ratio of extruded aluminum makes it suitable for many load-bearing and structural applications in aerospace.

What certifications are required for aerospace extrusions?

Aluminum used in planes can’t just be “good enough.” It must meet strict global standards.

Aerospace aluminum extrusions must meet certifications like AS9100, AMS material specs, and pass tests for strength, traceability, and consistency.

Common aerospace standards

| Certification or Spec | Účel |

|---|---|

| AS9100 | Aerospace-specific quality management |

| AMS (e.g. AMS-QQ-A-200) | Defines material and temper requirements |

| NADCAP | Audit for heat treating or coating |

| ISO 9001 | Base quality system standard |

Producers must control each stage—melting, extrusion, heat treatment, inspection—and keep detailed records. Without this, parts can’t be used in certified aircraft.

Most aerospace extrusions come with full documentation: mill certs, chemical analysis, mechanical test results, and full traceability.

AS9100 is a quality management standard required for aerospace extrusion suppliers.Pravda

AS9100 builds on ISO 9001 with additional requirements for product safety, risk management, and traceability in the aerospace industry.

How do extrusions perform in vibration testing?

Airplanes vibrate constantly—engines, wind, pressure shifts. Structural components must survive these stresses without cracking or loosening.

Extruded aluminum profiles are tested for fatigue and vibration. With proper alloy and temper, they pass aerospace vibration tests reliably.

Aluminum’s natural damping, along with high fatigue strength of 6000- and 7000-series alloys, makes it ideal for vibrating environments.

Performance factors

- No seams or welds: Continuous grain reduces crack risk

- Uniform geometry: Avoids stress concentrations

- Custom alloy + heat treat: Matches fatigue demands

Profiles often undergo cyclic fatigue testing, simulating years of flight. If the profile geometry is optimized, extrusions outperform many welded assemblies.

Well-designed extruded aluminum components can pass vibration and fatigue testing for aerospace use.Pravda

Extrusions made from proper alloys like 6061-T6 or 7075-T6 and tested under cyclic loads can meet the fatigue and vibration requirements in aerospace.

Are aerospace profiles customized per aircraft type?

There’s no universal aluminum part for all planes. Each aircraft has unique loads, shapes, and regulations.

Yes—most aerospace aluminum extrusions are fully customized to match aircraft-specific structures, loads, and space constraints.

Unlike standard construction extrusions, aerospace parts often require:

- Proprietary profile shapes

- Special alloys and heat treatments

- Tight tolerances and zero-defect requirements

Typical custom aerospace extrusions

| Komponenta | Role |

|---|---|

| Seat tracks | Secure seats with crash load design |

| Wing stiffeners | Carry aerodynamic loads |

| Fuselage rails | Align and support interior systems |

| Cargo floor beams | Resist heavy static and dynamic loads |

Suppliers keep profile catalogs with hundreds of custom parts, each matched to specific airframe programs.

Most aluminum extrusion profiles used in aerospace are custom-made for specific aircraft models.Pravda

Aircraft components have strict size, load, and certification needs that require custom profile designs rather than off-the-shelf options.

Závěr

Aluminum extrusion supports aerospace by delivering strong, lightweight, and customizable profiles that meet extreme design and regulatory needs. With proper certification and testing, these extrusions stand up to vibration, fatigue, and structural stress. Nearly every aerospace extrusion is custom-designed—because in aviation, precision and safety can’t be compromised.