Hliníkové výlisky vhodné pro eloxování?

Poor anodizing results often come from one wrong choice. The alloy. Many buyers face uneven color, weak layers, and surface defects. These problems raise cost and delay projects.

Aluminum extrusion alloys suitable for anodizing are those with low impurity levels, stable chemistry, and controlled microstructure, such as 6xxx series alloys, which form uniform and durable oxide layers under anodic treatment.

Many engineers focus on process control only. That is not enough. Alloy choice decides most of the final look and performance. Understanding this first step helps avoid quality risks later.

What alloy series suit anodizing the best?

Problems appear fast when the wrong alloy is anodized. Color mismatch. Streaks. Poor corrosion resistance. These issues often start at alloy selection, not at the anodizing tank.

The 6xxx aluminum alloy series suits anodizing best because it balances magnesium and silicon content, allowing a uniform oxide layer with good color response and strong adhesion.

Aluminum alloys behave very differently during anodizing. The oxide layer grows from the base metal. If alloying elements disrupt this growth, defects appear. Based on production experience and field feedback, some alloy families perform better than others.

Why 6xxx series dominates anodizing applications

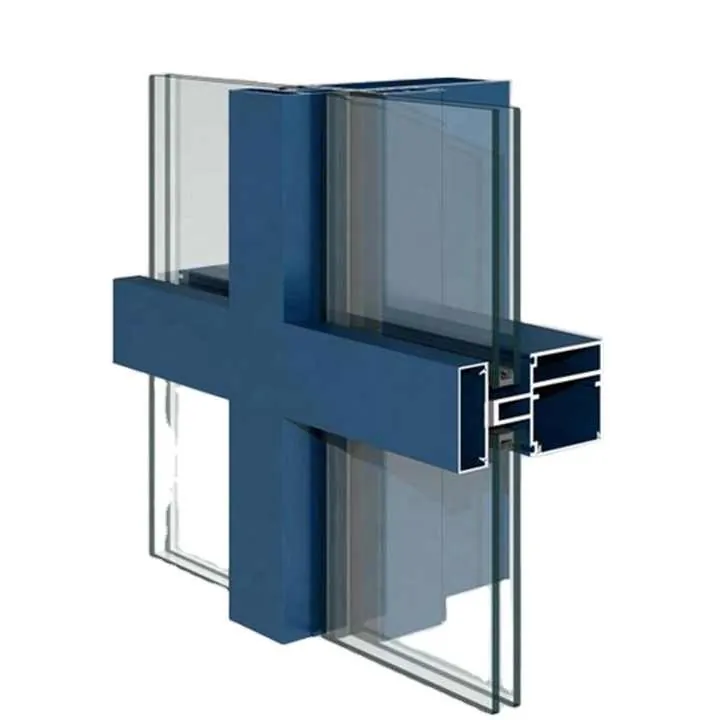

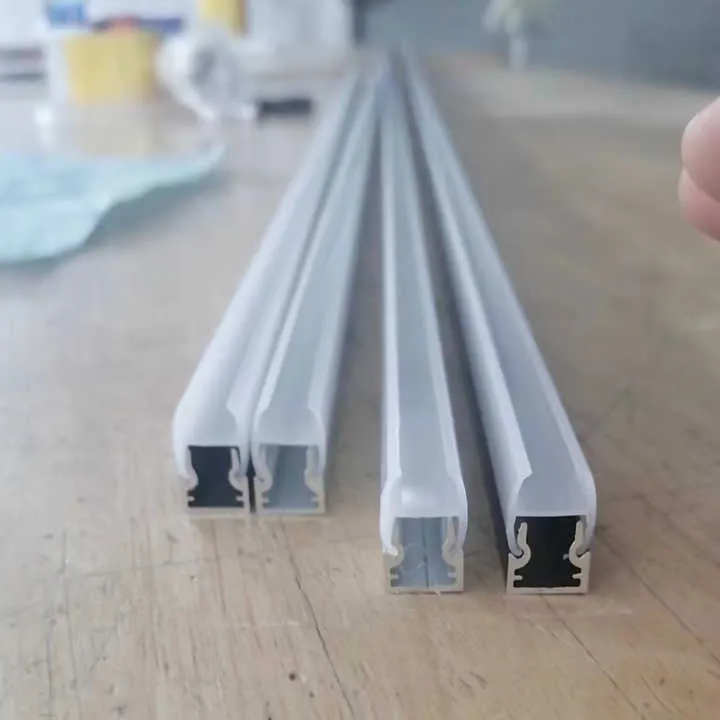

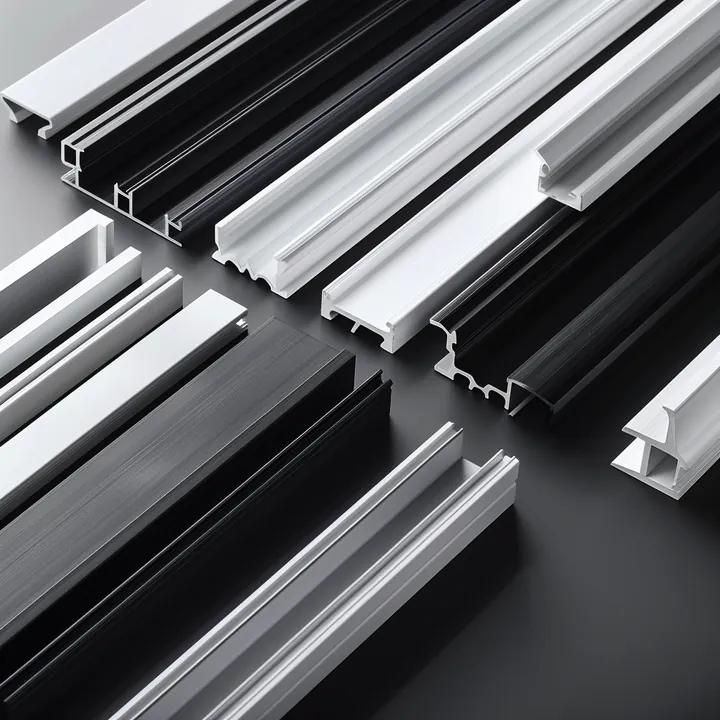

The 6xxx series includes 6063, 6061, and related grades. These alloys are widely used for architectural, industrial, and decorative extrusions. Their chemistry is stable and predictable.

Key reasons for their performance:

- Moderate magnesium content supports oxide growth

- Silicon improves extrusion flow without harming anodizing

- Low copper content reduces color variation

- Fine grain structure supports smooth surfaces

6063 is often called architectural alloy. This is not marketing language. It produces the most even anodized finish under mass production conditions. 6061 is stronger but still anodizes well when parameters are controlled.

Comparison of common anodizing alloys

| Slitina | Kvalita eloxování | Jednotnost barev | Typické použití |

|---|---|---|---|

| 6063 | Vynikající | Velmi vysoká | Facades, frames |

| 6061 | Dobrý | Vysoká | Structural parts |

| 6005A | Střední | Střední | Transport systems |

| 5052 | Střední | Střední | Sheet components |

| 7075 | Špatný | Nízká | Vysoce pevné díly |

The table shows a clear pattern. As alloy strength rises, anodizing quality often drops. This is due to added elements like copper and zinc.

Why other series struggle

2xxx and 7xxx series alloys contain copper and zinc. These elements do not oxidize evenly. During anodizing, they form dark spots or weak zones. This leads to poor appearance and reduced corrosion resistance.

5xxx alloys contain more magnesium. They can anodize, but color control is harder. In thick films, they may show gray or cloudy tones.

From a supplier view, the safest recommendation for anodizing remains 6063 or controlled 6061.

6xxx series aluminum alloys produce the most stable and uniform anodized surfaces among common extrusion grades.Pravda

Their balanced magnesium and silicon content supports even oxide layer growth and consistent color response.

7xxx series aluminum alloys are ideal for decorative anodizing due to their high zinc content.False

High zinc and copper levels disrupt oxide formation and cause color and surface defects during anodizing.

How does alloy purity influence oxide layer quality?

Many buyers assume anodizing is a coating. It is not. It is a controlled oxidation of the base metal. This means purity matters at every micron.

Higher alloy purity leads to a denser, more uniform oxide layer because fewer impurity particles interrupt oxide growth and electrical current flow during anodizing.

Purity does not mean pure aluminum only. It means controlled limits on unwanted elements. Iron, copper, and zinc are the most common troublemakers.

Role of impurity elements

During anodizing, current flows through the aluminum surface. Oxide grows upward and inward. Impurities block this flow. When blocked, oxide thickness becomes uneven.

Common impurity effects:

- Iron creates dark streaks

- Copper causes black spots

- Zinc lowers corrosion resistance

- Lead creates pinholes

Even small amounts matter. A change of 0.05 percent copper can alter final color.

Microstructure consistency

Purity also affects grain structure. Clean alloys form fine and even grains during extrusion. These grains respond evenly to anodizing current.

Poor purity leads to:

- Mixed grain sizes

- Segregation bands

- Uneven etching

- Patchy color zones

This is why two profiles with the same alloy name may anodize differently if sourced from different mills.

Practical purity guidelines for buyers

| Prvek | Recommended Max for Anodizing |

|---|---|

| Iron | <= 0.25 percent |

| Měď | <= 0.05 percent |

| Zinek | <= 0.10 percent |

| Lead | As low as possible |

These limits are stricter than standard alloy specs. They reflect real anodizing performance, not just chemical compliance.

From real production lines, tighter purity control reduces rejection rates. It also shortens anodizing cycle adjustments.

Lower impurity levels improve anodized layer density and visual consistency.Pravda

Fewer impurity particles allow even electrical flow and stable oxide growth.

Impurities only affect surface color and do not influence anodized layer thickness.False

Impurities disrupt current flow and directly affect oxide thickness and strength.

Can high-strength alloys be anodized effectively?

High strength often comes with hidden costs. Anodizing is one of them. Many engineers ask if strength and appearance can coexist.

High strength aluminum alloys can be anodized, but the results are often limited in color uniformity, layer integrity, and corrosion resistance compared to medium strength alloys.

Strength in aluminum usually comes from copper, zinc, or both. These elements interfere with anodizing chemistry.

Typical challenges with high strength alloys

High strength alloys like 2024 and 7075 show common problems:

- Dark or uneven color

- Burning at edges

- Reduced oxide adhesion

- Higher rejection rates

These issues do not always appear in small samples. They often show up in mass production.

When anodizing high strength alloys makes sense

There are cases where anodizing is still required:

- Letecké a kosmické komponenty

- Military equipment

- Functional corrosion protection

- Electrical insulation needs

In these cases, expectations must be adjusted. Clear anodizing performs better than colored anodizing. Thin films perform better than thick films.

Process adjustments that help

To improve results:

- Use lower current density

- Apply longer ramp-up times

- Choose sulfuric acid anodizing only

- Avoid organic dyes

Even with adjustments, results remain inferior to 6xxx series finishes.

Strength versus anodizing tradeoff

| Typ slitiny | Úroveň síly | Anodizing Appearance |

|---|---|---|

| 6063 | Střední | Vynikající |

| 6061 | Medium High | Dobrý |

| 2024 | Vysoká | Špatný |

| 7075 | Velmi vysoká | Very poor |

This tradeoff must be discussed early in design. Many redesigns happen too late because this issue is ignored.

High strength aluminum alloys can be anodized but often show inferior surface quality.Pravda

Copper and zinc content disrupt oxide formation and color consistency.

High strength aluminum alloys anodize better than 6xxx series alloys due to their dense structure.False

Their alloying elements interfere with anodizing despite higher mechanical strength.

Which surface treatments must precede anodizing?

Anodizing does not forgive mistakes. Surface preparation sets the base for everything that follows.

Surface treatments such as degreasing, alkaline etching, and desmutting must precede anodizing to ensure clean, reactive aluminum surfaces for uniform oxide growth.

Skipping or rushing preparation leads to permanent defects. Once anodized, flaws cannot be fixed.

Odmašťování

Extrusions carry oils from extrusion and handling. These oils block anodizing current.

Degreasing removes:

- Lubricants

- Fingerprints

- Packaging residue

Both alkaline and solvent degreasing can be used. Control time carefully to avoid staining.

Alkaline etching

Etching removes surface oxides and minor scratches. It also evens out extrusion marks.

Effects of proper etching:

- Uniform matte surface

- Reduced die lines

- Better color absorption

Over-etching causes dimensional loss and orange peel texture.

Desmutace

After etching, alloying residues remain. These are called smut. Desmutting removes them.

This step is critical for:

- Copper removal

- Iron particle removal

- Zinc residue removal

Nitric acid based desmutting is common.

Surface preparation flow

| Krok | Účel | Risk if Skipped |

|---|---|---|

| Odmašťování | Remove oils | Patchy oxide |

| Leptání | Surface leveling | Uneven color |

| Desmutace | Remove residues | Dark spots |

| Oplachování | Prevent carryover | Chemical stains |

Each step builds on the previous one. Poor control early creates visible defects later.

From long term production data, most anodizing complaints trace back to preparation, not anodizing tanks.

Proper surface preparation is essential for achieving uniform anodized finishes.Pravda

Each preparation step ensures clean and reactive aluminum surfaces for stable oxide growth.

Anodizing quality depends only on the anodizing bath and not on surface preparation.False

Surface contamination and residues directly cause anodizing defects if not removed.

Závěr

Choosing the right alloy and controlling purity and preparation decide anodizing success. Medium strength, clean 6xxx alloys with proper surface treatment deliver stable, repeatable results across large scale extrusion projects.