What affects the cost of custom aluminium profile moulds

When embarking on a project involving custom aluminium extrusions, understanding the costs of mould production is vital.

The cost of custom aluminium profile moulds is primarily determined by the profile’s cross-sectional area, structural complexity, metre weight, and choice of material such as alloy or H13.

While this overview provides a foundational understanding, delving deeper into each factor reveals the intricate balance of design requirements and cost-efficiency. Continue reading to uncover how these elements interplay to impact your budget.

The choice of alloy impacts mould cost.True

Different alloys have varying costs and machining requirements.

Metre weight does not affect mould pricing.False

Heavier profiles require more material and complex moulds.

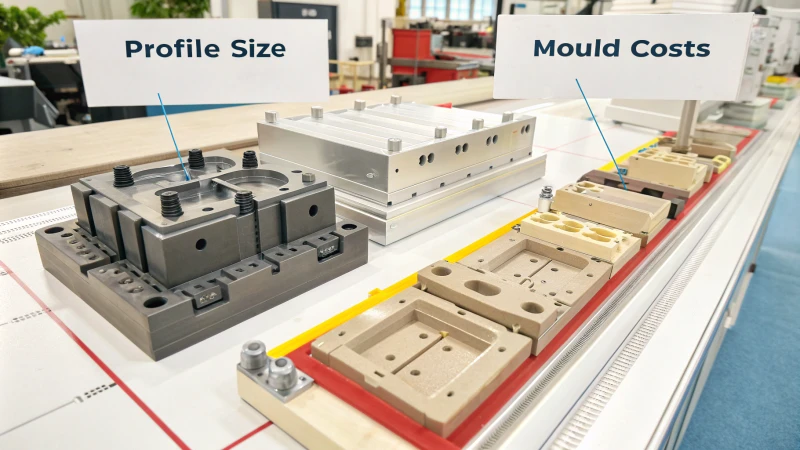

How Does Profile Size Influence Mould Costs?

Understanding how the size of a profile affects mould costs is crucial for optimizing manufacturing expenses. Let’s explore the factors involved.

Profile size impacts mould costs primarily due to the required cross-sectional area, structural complexity, and material type. Larger profiles often demand bigger, more expensive moulds.

Cross-Sectional Area and Mould Size

The cross-sectional area1 of an aluminium profile directly influences the mould size. Larger profiles require bigger moulds, leading to higher costs. For instance, a 100mm x 50mm profile necessitates a mould size of around 180mm-130mm.

Structural Complexity

Profiles with complex structures or hollow designs need specialized moulds, such as shunt moulds. These consist of multiple die sets, which elevate the overall cost. High precision requirements further complicate the design, demanding special pads.

| Structural Type | Mould Requirement | Cost Impact |

|---|---|---|

| Flat | Single set | Lower |

| Hollow | Shunt (multi-set) | Higher |

Metre Weight and Extruder Size

The metre weight2 of a product determines the necessary extruder size. Heavier products need larger extruders, increasing the pressure on the mould. This results in larger and thicker moulds, further escalating costs.

Material and Alloy Types

Using alloy moulds instead of standard H13 can significantly affect costs. Alloy moulds are more expensive but produce smoother surfaces and do not require de-nitriding. This is particularly advantageous for aesthetic applications like round pipes.

| Material Type | Surface Finish | De-nitriding Required | Cost |

|---|---|---|---|

| H13 | Standard | Yes | Lower |

| Alloy | Smooth and beautiful | No | Higher |

Understanding these factors aids in making informed decisions about profile design and material choices, ultimately impacting production expenses.

Consider exploring material types3 to optimize costs effectively.

Larger profiles require bigger moulds.True

Bigger moulds are needed for larger profiles, increasing costs.

Hollow designs use single set moulds.False

Hollow designs need shunt moulds, which are multi-set, raising costs.

Why Is Structural Complexity a Cost Factor?

Structural complexity can significantly affect the cost of manufacturing processes. Understanding how intricate designs influence expenses is crucial for optimizing budgets and maximizing efficiency.

Structural complexity increases costs due to the need for specialized tools, additional labor, and extended project timelines. These factors compound to elevate expenses, particularly in manufacturing and construction industries.

Understanding Structural Complexity

Structural complexity refers to the intricacy of a design or system, often requiring special attention in terms of resources and skills. In manufacturing, complex structures may involve unique moulds4 or custom components that drive up costs.

Cost Implications in Manufacturing

When a design features intricate details, it demands specialized machinery5 and expertise. For instance, a hollow aluminium profile requires a shunt mould, which consists of two die sets. This setup increases both material and labor costs.

| Structural Element | Cost Impact |

|---|---|

| Hollow Profiles | Higher due to dual moulds |

| Alloy Moulds | Elevated because of material costs |

The Role of Labor and Time

Complex designs often necessitate skilled labor, which can be more expensive. Additionally, longer production times are needed to meet high precision standards. The increased time requirements6 also contribute significantly to overall costs.

Example from the Aluminium Industry

In the aluminium profile sector, products with larger cross-sectional areas or higher metre weights need larger extruders. This results in increased pressure requirements7 for the moulds, further inflating costs. For instance, opening a special pad on a mould is dictated by the die set size, impacting both price and production timelines.

These factors illustrate how structural complexity can affect multiple aspects of cost management, including materials, labor, and time. Manufacturers must carefully evaluate these elements when planning projects.

Complex designs require specialized machinery.True

Intricate designs often need unique tools, raising manufacturing costs.

Simple designs have higher labor costs than complex ones.False

Complex designs typically require more skilled labor, increasing costs.

What Role Does Metre Weight Play in Pricing?

Metre weight significantly impacts pricing in industries like manufacturing and logistics. Understanding this metric can help businesses optimize costs and develop competitive pricing strategies.

Metre weight affects pricing by determining the material quantity needed and influencing production costs. It’s crucial in industries where weight impacts transportation, material cost, and manufacturing efficiency.

Understanding Metre Weight

Metre weight refers to the weight of a product per metre, crucial in determining the cost of raw materials and manufacturing efficiency8. For instance, in aluminium extrusion, heavier metre weights require larger extruders, increasing production costs.

| Product | Metre Weight (kg/m) | Cost Impact |

|---|---|---|

| Product A | 2.5 | Medium |

| Product B | 4.0 | High |

Material Cost Implications

The greater the metre weight, the more raw material is required, directly impacting pricing. Businesses must carefully calculate9 these costs to remain competitive while ensuring profitability.

Transportation Considerations

Heavier items often incur higher shipping costs, affecting overall product pricing. Companies should explore efficient logistics strategies to mitigate these expenses.

- Example: A company shipping aluminium profiles must consider the metre weight to optimize packaging and freight costs.

Industry-Specific Applications

In sectors like construction, understanding metre weight helps in assessing structural integrity and cost efficiency. This metric is essential for ensuring materials meet design specifications10.

| Sector | Importance of Metre Weight |

|---|---|

| Construction | High – Affects structural calculations |

| Manufacturing | Medium – Influences production process |

Understanding the role of metre weight in pricing is crucial for businesses aiming to optimize costs and improve competitiveness in their respective markets. By examining the effects of metre weight, companies can make informed decisions regarding material procurement, production processes, and logistics strategies. This understanding leads to better pricing models and enhanced market positioning.

Metre weight impacts raw material costs significantly.True

Heavier metre weights require more raw materials, increasing costs.

Lighter metre weight increases shipping costs.False

Heavier items incur higher shipping costs, not lighter ones.

Are Alloy Moulds More Expensive Than Standard Ones?

Navigating the choice between alloy and standard moulds can be crucial for manufacturers. Are alloy moulds really worth the extra cost? Let’s delve into the factors influencing their pricing.

Alloy moulds tend to be more expensive than standard ones due to their durability, precision, and high-quality output. They often offer better longevity and require less maintenance, justifying their higher initial cost.

Understanding the Cost Dynamics

When assessing whether alloy moulds are more expensive than standard ones, it is essential to consider several factors. The initial cost of alloy moulds is typically higher due to the materials used and the complex manufacturing processes involved.

| Factor | Alloy Moulds | Standard Moulds |

|---|---|---|

| Durability | High | Moderate |

| Precision | Excellent | Good |

| Maintenance | Low | Moderate |

Material and Manufacturing Costs

Alloy moulds often incorporate materials like high-grade steel or aluminum alloys, which inherently cost more. These materials offer superior durability and resistance to wear and tear. In contrast, standard moulds may utilize less robust materials, leading to more frequent replacements and maintenance.

The complexity of manufacturing an alloy mould also contributes to its higher price tag. Processes such as heat treatment and surface hardening are more intensive, enhancing the mould’s performance in high-pressure applications11.

Long-term Benefits

Despite the higher upfront investment, alloy moulds can prove economical in the long run. Their enhanced durability means they need fewer replacements, reducing downtime and increasing productivity. Businesses often find that this reliability and quality offset the initial expenditure.

Consider a scenario where a manufacturer needs a mould for a complex hollow structure. An alloy mould might be recommended due to its ability to handle high stress without deforming, which might not be possible with a standard mould.

Industry Use Cases

Industries that demand high precision, such as automotive or aerospace, often lean towards alloy moulds. The automotive industry12, for instance, requires components that can withstand extreme conditions without compromising on safety or functionality.

For companies prioritizing quality over cost, investing in alloy moulds is often seen as a strategic decision. They deliver products with superior surface finishes and dimensional accuracy, making them ideal for applications where aesthetics and precision are paramount.

In conclusion, while alloy moulds are generally more expensive upfront, their potential for reduced maintenance costs and higher-quality output make them a viable option for many manufacturers seeking long-term gains.

Alloy moulds cost more due to complex manufacturing.True

Alloy moulds require intensive processes like heat treatment, raising costs.

Standard moulds need less maintenance than alloy ones.False

Alloy moulds have lower maintenance needs due to superior durability.

How Can You Optimize Mould Design for Cost Efficiency?

Mould design plays a crucial role in manufacturing, directly impacting production costs. Discover practical strategies to optimize mould design for cost efficiency, maintaining quality without breaking the bank.

Optimizing mould design for cost efficiency involves minimizing material usage, simplifying designs, choosing appropriate materials, and enhancing the production process. Focus on these elements to reduce costs while ensuring quality.

Simplifying Design Structures

Simplifying mould designs can significantly reduce manufacturing costs. By minimizing the number of complex features, you decrease machining time and material waste. A streamlined design also lowers the risk of defects, enhancing quality control. Consider incorporating modular components or utilizing advanced software to simulate design efficiency13.

Material Selection and Optimization

Selecting the right material for your mould is pivotal. High-performance materials may seem expensive upfront but can reduce long-term costs through durability and reduced maintenance. Investigate alternatives such as hybrid materials that offer strength and flexibility. A table comparing material properties might help in selecting suitable options:

| Material Type | Cost | Durability | Maintenance Needs |

|---|---|---|---|

| H13 Steel | Medium | High | Low |

| Alloy Steels | High | Very High | Very Low |

| Hybrid Composites | Variable | Moderate | Medium |

Advanced Manufacturing Techniques

Employing techniques like additive manufacturing or CNC machining can enhance precision while saving material costs. These technologies allow for intricate designs without excessive waste. Implementing these techniques14 can lead to significant cost reductions.

Process Efficiency Improvements

Enhancing the efficiency of your production process can lead to cost savings. Implementing lean manufacturing principles, reducing downtime, and optimizing machine utilization are essential strategies. Consider using sensors or IoT devices to monitor production efficiency15 in real-time, enabling proactive adjustments.

Collaborative Design Approach

Engaging with suppliers early in the design phase can yield insights into material availability and cost-effective alternatives. A collaborative approach ensures designs meet both functional and economic requirements, potentially uncovering innovative cost-saving measures16.

Simplifying mould designs reduces manufacturing costs.True

Streamlined designs decrease machining time and material waste.

High-performance materials increase long-term costs.False

They reduce long-term costs through durability and less maintenance.

Conclusion

The cost of custom aluminium profile moulds is influenced by cross-sectional area, structural complexity, metre weight, and material choice, impacting overall manufacturing expenses.

-

This link provides a deeper understanding of how cross-sectional area affects mould design and costs. ↩

-

This link elaborates on the relationship between metre weight and extruder requirements, influencing cost. ↩

-

This resource offers insights into choosing between H13 and alloy moulds for optimal cost efficiency. ↩

-

This link will provide detailed insights into unique moulds, helping readers understand how they contribute to cost increases. ↩

-

Clicking this link helps readers grasp how specialized machinery influences costs and efficiency in production. ↩

-

Explore this link to learn about the impact of extended production times on overall project costs. ↩

-

This link provides information on pressure requirements in aluminium extrusion, essential for understanding cost factors. ↩

-

Discover how metre weight influences manufacturing processes and efficiency in various industries. ↩

-

Learn effective methods to accurately calculate material costs using metre weight measurements. ↩

-

Explore why metre weight is crucial in construction design and its impact on material selection. ↩

-

Understanding high-pressure applications reveals where alloy moulds excel, offering insights into their superior performance. ↩

-

Exploring automotive preferences highlights the critical role of durability and precision in choosing alloy moulds. ↩

-

Exploring CAD software benefits can reveal ways to enhance design efficiency, reducing costs and improving precision. ↩

-

Understanding additive manufacturing advantages can showcase how this method reduces waste and cost in complex designs. ↩

-

Discovering how IoT enhances process efficiency helps in implementing cost-effective monitoring solutions. ↩

-

Collaborative strategies can highlight cost-saving measures by leveraging supplier expertise early in the design process. ↩