CNC Machining Zambia: Manufacturers & Industry Guide

Part 1: Market Size and Growth

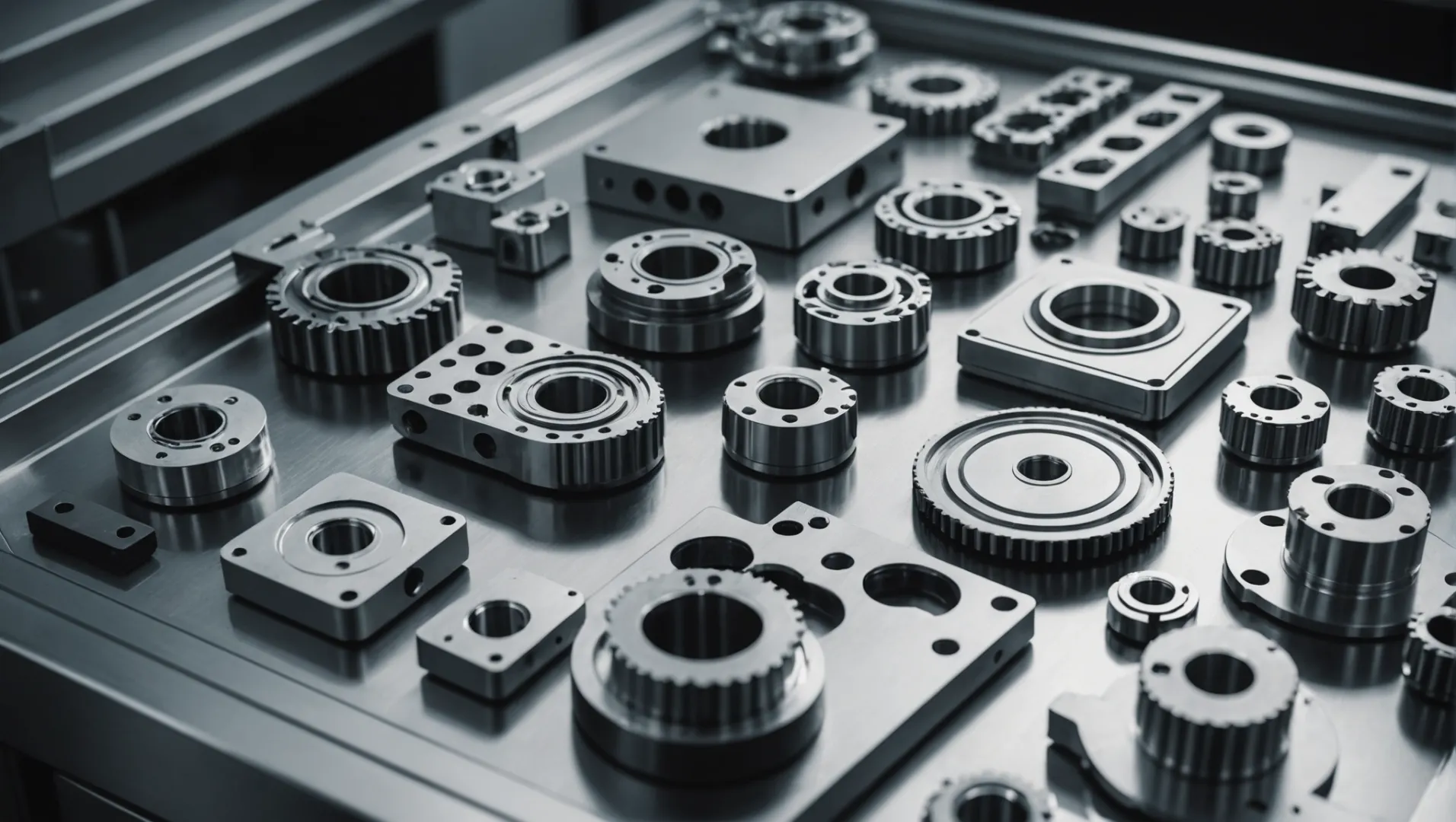

Zambia’s industrial base is still developing, but its potential for precision machining is growing rapidly. The country’s economy revolves around mining, agriculture, and infrastructure, all of which require precision-made components, repairs, and metal fabrication. CNC machining is now becoming a cornerstone for workshops aiming to improve efficiency, accuracy, and reliability.

Demand for CNC machining in Zambia has emerged mainly from heavy equipment users in mining and construction. These sectors often face high costs and long waiting times when importing mechanical parts. By producing components locally-such as flanges, shafts, valve bodies, and machine parts-CNC workshops can dramatically reduce downtime. The introduction of computer-controlled manufacturing in cities like Lusaka, Kitwe, and Ndola shows a shift toward modernized production and repair services.

However, the local CNC ecosystem faces challenges. Import duties on machines and tooling remain high, and skilled operators are limited. Power interruptions, lack of advanced metrology tools, and limited access to cutting inserts also slow adoption. Despite this, workshops are learning to blend manual machining expertise with digital precision. The combination of skilled technicians and new technology forms the foundation of Zambia’s precision engineering future.

Part 2: Leading Companies

Below are examples of Zambia’s most representative CNC and metalworking companies. Each one contributes to the country’s growing capacity for precision manufacturing and repair.

African Engineering Services Ltd

Contact Now

African Engineering Services (AES) is one of Zambia’s largest mechanical workshops. Its facilities in Kitwe and Solwezi provide CNC turning, milling, rod grinding, and cylinder honing.

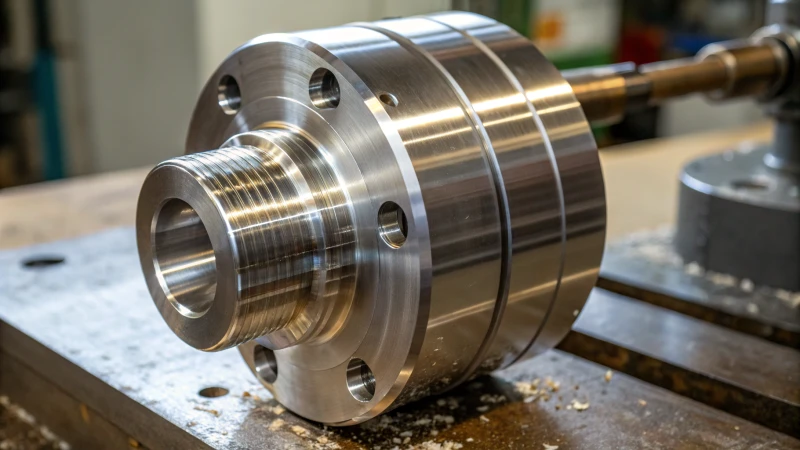

AES supports major mining clients and energy plants by fabricating and restoring components such as shafts, clevises, and barrels. The workshop is capable of machining parts up to several meters in length, demonstrating its capability for heavy industry. The company’s advantage lies in combining traditional mechanical repair with CNC precision, allowing it to meet both repair and new-part production demands.

CP Engineering Limited

Contact Now

CP Engineering is a respected name in Zambia’s Copperbelt industrial region. It provides gear manufacturing, bolt machining, and general precision fabrication.

Their workshop uses both CNC and conventional lathes and mills to produce couplings, sprockets, sleeves, and studs. Their team handles multiple materials, including stainless steel, aluminum, and mild steel. CP Engineering’s reputation for reliability has made it a consistent supplier for mining, manufacturing, and structural projects. Their knowledge of tooling and quality control is one of their greatest strengths.

Mechanical Spares & Services (MSS)

Contact Now

MSS operates one of the region’s better-equipped machine shops. It provides CNC milling, turning, grinding, and mechanical repair services.

Located in Kitwe’s heavy industrial area, MSS serves both maintenance and fabrication needs. The company focuses on quick delivery, custom work, and precision repair. Its shop supports mining, cement production, and transport maintenance firms. MSS has invested in operator training and measurement tools to ensure dimensional accuracy. The balance of traditional craftsmanship and CNC automation gives it strong operational flexibility.

Saloba Ltd

Contact Now

Saloba Ltd is a Kitwe-based fabrication and machining company with both CNC and manual machining capabilities.

The firm manufactures shafts, sleeves, and custom mechanical parts for local clients. They also handle welding, bending, and assembly, providing complete metalwork solutions. Saloba’s advantage is adaptability-its workshop accepts one-off custom projects as well as small production runs. Their focus on local service and fast turnaround makes them a trusted partner for Zambian industries.

Non-Ferrous Metal Works (Z) Ltd

Contact Now

Non-Ferrous Metal Works is a Ndola-based foundry and machine shop that provides casting and CNC finishing services.

The company manufactures parts from bronze, brass, and aluminum, then machines them into finished components. Their integrated workflow-casting followed by CNC machining-reduces dependence on imported parts and improves production control. They supply the mining, manufacturing, and energy sectors with spare parts, couplings, and precision fittings.

| Company | Founded | Core Services | Industries Served | Strengths |

|---|---|---|---|---|

| African Engineering Services | 2000s | CNC machining, rod grinding, refurbishment | Mining, energy, industrial | Large-part machining, integrated services |

| CP Engineering | 1990s | Machining, gear & bolt production | Mining, construction | Skilled workforce, tooling knowledge |

| Mechanical Spares & Services | 2010s | CNC turning, milling, grinding | Mining, maintenance | Quick turnaround, hybrid capability |

| Saloba Ltd | 2010s | Custom machining & fabrication | Construction, industry | Flexible service, precision output |

| Non-Ferrous Metal Works | 1980s | Casting & CNC machining | Mining, manufacturing | Vertical integration from casting to finish |

Part 3: Trade Shows and Industry Events

Zambia International Trade Fair

The Zambia International Trade Fair is the country’s largest industrial event. It gathers local manufacturers, suppliers, and international partners. CNC workshops and machinery distributors use it to showcase capabilities, find clients, and network with mining and engineering companies.

The fair also serves as an educational platform where young engineers and technicians can explore modern manufacturing technologies, automation systems, and CNC machinery applications.

Copperbelt Mining & Industrial Expo

This event focuses on Zambia’s Copperbelt region-the country’s industrial heart.

Exhibitors include heavy machinery companies, tool suppliers, and engineering firms. For CNC workshops, it offers exposure to new cutting tools, measurement instruments, and digital manufacturing systems. It also helps connect Zambian firms with regional partners from South Africa and other neighboring countries.

| Event | Frequency | Location | Highlights |

|---|---|---|---|

| Zambia International Trade Fair | Annual | Lusaka | Manufacturing, engineering, partnerships |

| Copperbelt Mining & Industrial Expo | Annual | Kitwe / Ndola | Mining tech, machine tools, CNC innovation |

Part 4: Impact of Global Trade Policies

Zambia’s CNC machining industry depends on imported machine tools, electronic controls, and consumables such as cutting inserts, bearings, and lubricants. Import duties and complex customs procedures often make these inputs expensive and difficult to obtain.

Workshops frequently rely on regional suppliers from South Africa or overseas shipments through Dar es Salaam or Durban ports. High logistics costs add pressure to maintain profitability. This environment has pushed many local shops to become resourceful and repair-oriented, extending machine life and reusing components whenever possible.

Global trade trends-like shifting supply chains and regional trade agreements-can both help and hinder Zambia’s machining growth. If trade agreements within southern Africa improve, tooling and equipment could become cheaper and more accessible. On the other hand, fluctuations in global metal prices and shipping costs affect small manufacturers’ cash flow and investment ability.

Energy stability remains a concern. CNC machines require reliable electricity for consistent performance. Many workshops invest in backup generators to ensure productivity. Improvements in Zambia’s power grid could greatly enhance manufacturing reliability.

Another major factor is skills development. Local institutions, including technical colleges, are starting to offer CNC programming and CAD/CAM design courses. This effort aims to close the skills gap and prepare the next generation of machinists and mechanical engineers. With continued support, Zambia can build a self-sustaining ecosystem of skilled professionals and industrial competence.

International collaboration also plays a role. Regional partners provide training, equipment donations, and supplier networks. If Zambia continues improving its trade environment and encourages investment in industrial education, CNC machining could become a catalyst for diversification and export growth.

Part 5: Conclusion

CNC machining in Zambia is entering a new phase of growth. Though still small, the sector is increasingly important for the country’s industrial resilience. Companies such as African Engineering Services, CP Engineering, Mechanical Spares & Services, Saloba Ltd, and Non-Ferrous Metal Works are leading the transformation by introducing digital precision and quality control into traditional metalworking.

The path forward will depend on sustained investment, better access to imported tooling, and training for local operators. Workshops that embrace CNC automation, quality standards, and faster turnaround times will gain a competitive edge both locally and regionally.

As Zambia strengthens its manufacturing base, CNC machining will become central to reducing import dependency, supporting mining infrastructure, and fostering industrial independence. In the next decade, with improved infrastructure and policy support, Zambia could emerge as a regional hub for precision engineering-combining craftsmanship with computer precision to build a stronger, more self-reliant industrial future.

Recommended Reading:

- CNC Machining Nicaragua: Manufacturers & Industry Guide

- CNC Machining Kyrgyzstan: Manufacturers & Industry Guide

- CNC Machining Zimbabwe: Manufacturers & Industry Guide

- CNC Machining Georgia: Manufacturers & Industry Guide

- CNC Machining Malta: Manufacturers & Industry Guide

- CNC Machining Cape Verde: Manufacturers & Industry Guide

- CNC Machining Suriname: Manufacturers & Industry Guide

- CNC Machining Myanmar: Manufacturers & Industry Guide

What Are the Advantages of Extruded Aluminum Heat Sinks?

LED Heat Sink

6061 Aluminum Extrusion Round Tube For Industry

Customized Extruded Aluminum Enclosure Profile