CNC Machining Sweden: Manufacturers & Industry Guide

Part 1: Market Size and Growth

CNC machining in Sweden has become a critical part of its advanced industrial base. The country is known for engineering excellence, precision, and innovation, which naturally extend into machining technologies. Sweden’s strong automotive, aerospace, and medical equipment sectors rely heavily on CNC parts and high-end machining solutions.

The market size is difficult to define precisely, but Swedish CNC companies are well integrated into global supply chains. From producing components for Volvo and Scania trucks to precision parts for aircraft and surgical tools, applications cover a broad spectrum. The Swedish focus on sustainability and digital transformation also influences how CNC machining develops in the country.

Industrial clusters, government policies, and investment in R&D have all shaped the sector. Sweden encourages high-tech manufacturing through incentives for automation and Industry 4.0 integration. This has made local companies pioneers in flexible production, robotics, and smart machining systems.

Part 2: Leading Companies

Sandvik Coromant

Contact Now

Sandvik Coromant, founded in 1942 and based in Sandviken, is one of the world’s leading suppliers of cutting tools and machining solutions. While it is best known globally for tooling, it also plays a vital role in developing CNC machining processes.

Its products support industries like aerospace, automotive, and energy. Sandvik provides complete machining solutions, combining hardware, digital tools, and training. The company is known for its innovation and leadership in sustainable machining practices. It holds ISO certifications and has won international awards for research and development.

SKF Precision Machining

Contact Now

SKF, based in Gothenburg and founded in 1907, is globally recognized for bearings, but it also has advanced CNC machining operations. SKF Precision Machining focuses on producing high-accuracy components for bearings, seals, and mechatronics.

SKF’s CNC capabilities support the automotive, wind energy, and industrial machinery sectors. Its production integrates automation and robotics to ensure consistent quality. SKF’s machining operations are certified to international standards and showcase advanced digital monitoring systems. The company is widely respected for its technical expertise and sustainability focus.

AQ Group

Contact Now

AQ Group, founded in 1994 in Västerås, is a multinational engineering company with strong CNC machining operations. It provides precision machining services for industries including automotive, railway, and defense.

AQ Group specializes in CNC turning, milling, and assembly of complex components. Its facilities operate with strict quality systems and lean manufacturing principles. The company is known for flexibility and customer-specific solutions. AQ Group has earned ISO/TS certifications and recognition for its export contributions.

| Company | Founded | Core Products | Industries | Certifications |

|---|---|---|---|---|

| Sandvik Coromant | 1942, Sandviken | Cutting tools, machining solutions | Aerospace, Automotive, Energy | ISO, R&D awards |

| SKF Precision Machining | 1907, Gothenburg | Bearings, seals, CNC components | Automotive, Energy, Industrial | ISO standards |

| AQ Group | 1994, Västerås | CNC turning, milling, assemblies | Automotive, Railway, Defense | ISO/TS certifications |

Part 3: Trade Shows and Industry Events

Elmia Subcontractor

Elmia Subcontractor is Sweden’s leading trade show for subcontracting industries, held annually in Jönköping. It gathers suppliers and buyers across Europe, with CNC machining companies strongly represented.

The event highlights precision engineering, digital solutions, and sustainable manufacturing practices. It is a meeting place for decision-makers and engineers seeking partnerships in high-value industries. Live demos and networking opportunities make it a major platform for Swedish CNC companies.

Tekniska Mässan (Swedish Industry Fair)

Tekniska Mässan in Stockholm is a broad industry exhibition focusing on automation, production technologies, and machining. CNC companies use this event to display new equipment, services, and smart factory solutions.

The event attracts manufacturers, technology providers, and engineers from the Nordic region. Highlights include robotics integration, CAD/CAM solutions, and advanced CNC systems. It has become a space where Swedish and international companies connect for collaboration and innovation.

| Event | Date | Location | Highlights |

|---|---|---|---|

| Elmia Subcontractor | November (annual) | Jönköping | Precision engineering, networking, demos |

| Tekniska Mässan | Biennial | Stockholm | Robotics, CNC innovations, CAD/CAM solutions |

Part 4: Impact of Global Trade Policies

Global trade policies affect Sweden’s CNC machining industry in several ways. As part of the European Union, Sweden enjoys access to a large single market with streamlined export rules. This gives Swedish CNC companies an edge in exporting to automotive and aerospace clients.

However, international supply chain disruptions and global competition put pressure on Swedish manufacturers. Companies must navigate rising material costs and stricter environmental regulations. Sweden’s strong environmental standards also drive innovation in cleaner machining technologies.

At the same time, reshoring trends in Europe create opportunities for Swedish firms. Clients increasingly prefer suppliers closer to home for better resilience. Swedish CNC companies can benefit by offering high-quality, sustainable, and flexible production capabilities. This balance of risk and opportunity shapes the country’s CNC machining future.

Part 5: Conclusion

Sweden’s CNC machining industry is advanced, export-oriented, and innovation-driven. It serves demanding industries like aerospace, automotive, and medical equipment, while also pioneering sustainable and digital solutions. With strong industrial clusters and leading global companies, Sweden remains at the forefront of CNC machining in Europe.

Still, challenges exist. Global competition, supply chain volatility, and regulatory pressure require constant adaptation. Companies must continue to innovate in automation, sustainability, and digital integration. The future of Sweden’s CNC machining lies in its ability to combine precision with innovation and resilience.

Recommended Reading:

CNC Machining Indonesia

CNC Machining Turkey

CNC Machining Netherlands

CNC Machining Saudi Arabia

CNC Machining Switzerland

CNC Machining Taiwan

CNC Machining Iran

CNC Machining Poland

What Options Exist for Connecting Aluminum Window Frame Extrusions?

Aluminum Boat Trim Manufacturer

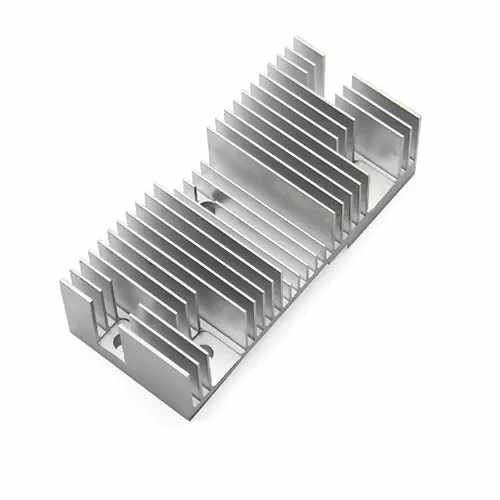

Machined Heatsink for Custom Thermal Solutions

Customized OME Aluminium Profile Extruded With The Anodized Black Champage Silver White And Blasted Treatment