CNC Machining Nepal: Manufacturers & Industry Guide

Part 1: Market Size and Growth

Over the past few years, I have been watching how Nepal’s light manufacturing industry is changing. More local workshops are now exploring ways to bring CNC machining technology into their production. Even though the industry is still small, I see clear potential for growth. CNC machining allows local firms to make metal and plastic components with higher precision and lower waste, which supports industrial modernization.

Nepal’s CNC machining market remains in its early stage. Demand mainly comes from small equipment manufacturers, automotive repair shops, and construction-related metal fabrication. Some firms use CNC routers for signage and architectural metalwork, while others start adopting CNC lathes for mechanical components. The combination of domestic repair demand and light manufacturing gives a base for gradual growth.

Government programs that promote entrepreneurship and small industry development have helped some firms buy entry-level CNC machines. However, challenges like limited capital, skill gaps, and import dependency for materials still slow progress. Yet I believe that with regional cooperation and targeted training, Nepal’s machining industry can find its place in the South Asian manufacturing map.

Part 2: Leading Companies

Several Nepali companies are experimenting with or actively using CNC technology in their services. Here are a few that represent different capabilities across the country.

Himal Signage

Contact Now

Himal Signage is one of the best-known metal cutting and signage solution providers in Nepal. Founded in the 2010s, it focuses on CNC cutting, laser engraving, and metal sheet fabrication. The company uses CNC routers to cut aluminum, steel, and acrylic materials for signs, panels, and decorative installations.

Their clients come from advertising, construction, and commercial decoration sectors. Himal Signage’s key strength is flexibility and design accuracy, allowing customized cuts for complex architectural patterns. Although it focuses mainly on signage, the company’s technical knowledge in CNC routing is transferable to precision fabrication. It operates mainly in Kathmandu and serves clients nationwide.

Nepal Construction Mart

Contact Now

Nepal Construction Mart provides metal machining, repair, and fabrication services for construction and mechanical projects. While its primary focus is on heavy-duty fabrication, it also integrates CNC milling and turning for customized parts and repair work. This combination of conventional and CNC processes improves consistency and part interchangeability.

The company serves construction firms, small industrial plants, and machine repair workshops. It offers welding, machining, turning, and component assembly services. Their advantage lies in their ability to handle on-site machining and maintenance, which saves clients time and logistics cost. Even though the company does not advertise international certifications, its versatility and practical expertise make it a valuable part of Nepal’s industrial ecosystem.

Nepal Laser Craft Industry

Contact Now

Nepal Laser Craft Industry specializes in laser cutting, metal machining, welding, and finishing. Founded around the mid-2010s, it bridges the gap between creative design and mechanical precision. The company combines CNC cutting with laser engraving and surface processing for both artistic and industrial clients.

Its main industries include manufacturing, construction, decorative metalwork, and custom fabrication. A key innovation is the integration of cutting, heat treatment, and polishing under one roof. This approach helps customers reduce outsourcing steps and control quality better. Although still young, the company represents how Nepali firms are slowly merging creative and industrial machining skills to serve broader markets.

Comparison Table

| Company | Founded | Core Products / Services | Industries Served | Certifications / Honors |

|---|---|---|---|---|

| Himal Signage | 2010s | CNC cutting, routing, engraving | Advertising, architecture, construction | — |

| Nepal Construction Mart | 2010s | CNC machining, welding, metal repair | Construction, machinery repair | — |

| Nepal Laser Craft Industry | Mid-2010s | Laser cutting, machining, heat treatment | Manufacturing, decorative metal | — |

Part 3: Trade Shows and Industry Events

Trade shows in Nepal are relatively small, but they play an important role in connecting suppliers, buyers, and technology distributors. They give local engineers a chance to explore machine tools, automation software, and industrial materials.

Nepal Engineering and Industrial Expo

This event, often held in Kathmandu or Pokhara, gathers local machinery suppliers, metal fabricators, and CNC equipment resellers. Exhibitors show machining samples, metal components, and machine demonstrations. Visitors include entrepreneurs, engineers, and students learning mechanical technologies. It helps small firms discover new suppliers and understand regional manufacturing trends.

The show often runs for three to five days and includes seminars about industrial automation, safety, and quality control. For me, what stands out is the enthusiasm of young engineers who present locally designed prototypes and small CNC conversions of traditional lathes.

South Asia Manufacturing & Machine Tool Expo

Although it is held outside Nepal—in India, Bangladesh, or Thailand—many Nepali entrepreneurs attend this expo. It features CNC machine tools, cutting systems, and smart manufacturing solutions. Nepali firms often visit to learn about toolpath optimization, CAM software, and lean machining methods.

The exposure from such international events allows local entrepreneurs to import smaller CNC machines suitable for the Nepali market. It also encourages collaboration between Nepali workshops and Indian or Chinese suppliers of spare parts and cutting tools.

Summary of Events

| Event | Date | Location | Highlights |

|---|---|---|---|

| Nepal Engineering and Industrial Expo | Annual / Varies | Kathmandu or Pokhara | Local CNC demos, fabrication displays, workshops |

| South Asia Manufacturing & Machine Tool Expo | Annual | India / Bangladesh / Thailand | Smart machining, automation, CAM demonstrations |

Part 4: Impact of Global Trade Policies

Nepal’s CNC machining sector is heavily influenced by trade policies and cross-border logistics. Because Nepal is landlocked, imports of machines, cutting tools, and materials mostly come through India. This dependency means tariffs, customs delays, and exchange rate fluctuations can affect operating costs and delivery schedules.

Free trade frameworks like SAFTA (South Asian Free Trade Area) have created some benefits for small manufacturers, reducing duties on raw materials and machine imports. However, bureaucratic delays still make it hard for small workshops to maintain consistent supply of tooling and parts. I’ve seen firms stockpile inserts and lubricants to avoid interruptions caused by transport congestion.

Another risk comes from limited access to foreign exchange, which makes it harder for firms to buy advanced machines from Japan, Germany, or China. Many rely on refurbished units imported through India. This affects accuracy and reliability, but it also shows how resourceful Nepali workshops can be. They often modify and maintain old equipment to extend its life.

Looking forward, trade partnerships with India and China could make CNC equipment more affordable. Localized service networks, training, and shared machine hubs could also reduce entry barriers for small firms. If properly managed, Nepal’s machining sector could tap into regional supply chains and gain more export potential.

Part 5: Conclusion

From what I’ve seen, CNC machining in Nepal is still young but full of promise. It reflects a generation of entrepreneurs who are blending creativity, mechanical skill, and business sense to fill a gap in precision fabrication. The opportunity lies in catering to small-batch, high-mix, quick-turn projects where flexibility matters more than volume.

To grow, Nepali firms need to focus on quality consistency, training programs, and tool management. Partnerships with regional suppliers can improve access to better materials and software. Over time, building a skilled labor base and stronger logistics network will help the country climb the manufacturing value chain.

Challenges will continue—especially financing, training, and machine maintenance—but the spirit of innovation is visible. As the ecosystem matures, CNC machining could become a strategic industry, supporting everything from local repair shops to export-grade component manufacturing. Nepal may not rival industrial giants soon, but its determination to adopt precision technology shows that progress, even small steps, is well underway.

Recommended Reading:

CNC Machining Macedonia

CNC Machining Latvia

CNC Machining Estonia

CNC Machining Lebanon

CNC Machining Jordan

CNC Machining Paraguay

CNC Machining Uruguay

CNC Machining Sri Lanka

6061 Aluminum Alloy – Decoding Properties and Uses?

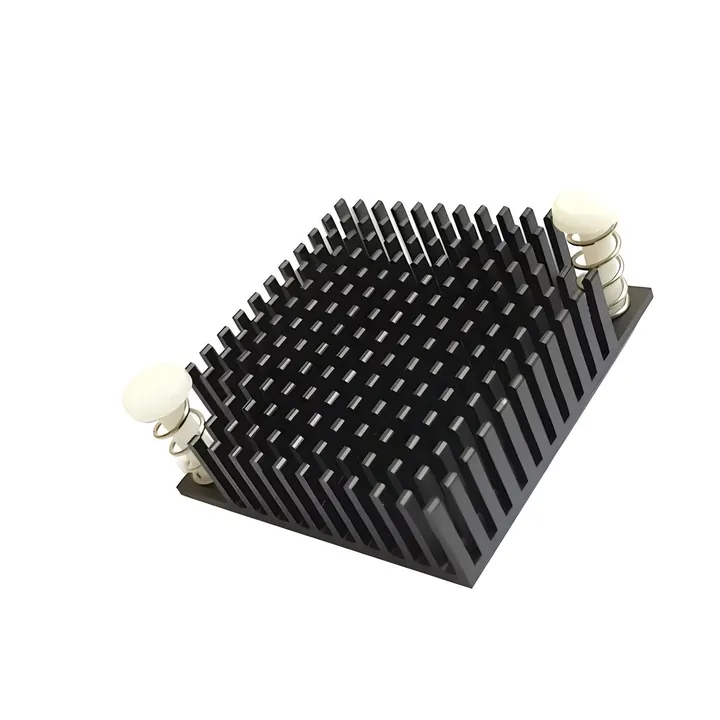

Extruded Heat Sink Supplier

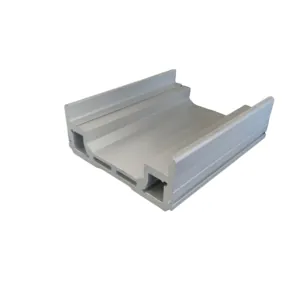

Aluminum Extrusion Custom Electric Vehicle Battery Enclosure Aluminum Profile

Anodized Aluminum Profile Kitchen Cabinet Frame