CNC Machining Georgia: Manufacturers & Industry Guide

Part 1: Market Size and Growth

When I first studied Georgia’s manufacturing landscape, I found that CNC machining plays a major role in the state’s precision manufacturing ecosystem. Georgia combines a strategic location, world-class logistics, and a strong technical workforce, making it one of the most competitive states in the southeastern United States.

The state’s CNC machining industry supports a wide range of sectors including aerospace, automotive, defense, agriculture, and energy. With strong infrastructure such as the Port of Savannah, regional airports, and major interstates, Georgia offers unmatched access for domestic and global supply chains. Demand for precision parts is rising as companies pursue faster prototyping, tighter tolerances, and higher production flexibility.

Recent trends show steady growth in multi-axis machining, automation integration, and additive manufacturing. Georgia’s machine shops are evolving from simple part producers to full-service engineering partners, offering design support, reverse engineering, and just-in-time manufacturing. With continued investment in advanced equipment and skilled labor, Georgia’s CNC industry is on track for sustained expansion.

Part 2: Leading Companies

Georgia hosts hundreds of precision machining firms, from small family-owned workshops to large aerospace suppliers. Here are three representative examples showing the diversity of capabilities in this sector.

Aerotech Machining (Savannah, Georgia)

Contact Now

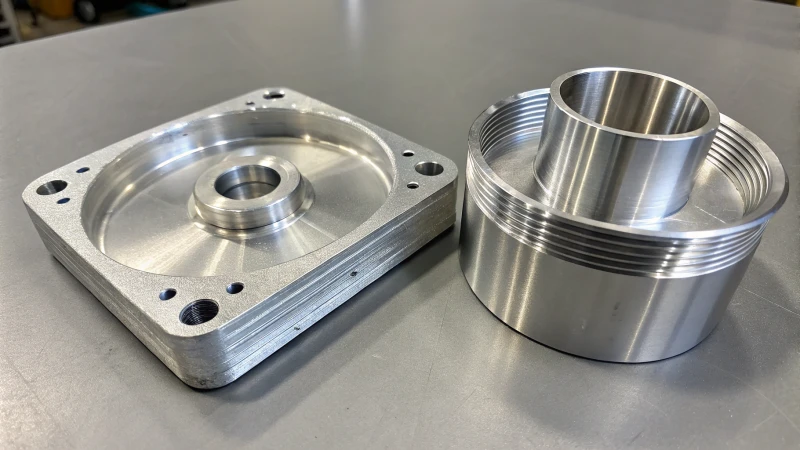

Aerotech Machining specializes in high-precision components and assemblies for the aerospace, energy, and heavy equipment industries. The company provides CNC milling, turning, and complex 5-axis machining with advanced CAD/CAM integration.

Its strength lies in tight tolerances and consistent quality, supported by advanced inspection systems and certified processes. Aerotech’s reputation is built on on-time delivery, engineering collaboration, and custom small-batch manufacturing. The firm continues to invest in automation and operator training to stay ahead of global competition.

RAM Tool, Inc. (Columbus, Georgia)

Contact Now

RAM Tool, Inc. has operated for decades as a tool and die specialist serving multiple industries in Georgia and the broader Southeast. It provides CNC machining, die manufacturing, and mold repair, offering clients a one-stop solution from design to production.

The company serves automotive, defense, and energy clients, focusing on tool precision and process control. Its innovation lies in integrating machining with additive manufacturing and die refurbishing services. With ISO certification and modern inspection equipment, RAM Tool continues to expand its technical capacity and workforce training programs.

Southern Precision Machining (Atlanta, Georgia)

Contact Now

Southern Precision Machining is a mid-sized CNC production shop located near Atlanta. The company delivers custom prototypes, small batch parts, and production runs across industries such as medical devices, construction, and electronics.

Their value lies in flexibility: the team offers fast quoting, material sourcing, and quick-turn machining for both metals and plastics. Their innovation comes from blending CNC technology with lean manufacturing and real-time quality monitoring. Southern Precision is known for customer-focused service and competitive turnaround times.

Company Comparison Table

| Company Name | Location | Core Services / Products | Industries Served | Certifications / Differentiators |

|---|---|---|---|---|

| Aerotech Machining | Savannah, GA | 5-axis CNC, precision assemblies | Aerospace, energy, heavy industry | Tight tolerances, advanced quality systems |

| RAM Tool, Inc. | Columbus, GA | Tool & die making, CNC machining, molds | Automotive, defense, manufacturing | Integrated tool design & production |

| Southern Precision Machining | Atlanta, GA | Custom CNC parts, prototyping, production | Medical, electronics, construction | Lean production, short lead times |

Part 3: Trade Shows and Industry Events

Georgia’s CNC and manufacturing firms participate in a number of national and regional events to connect with technology providers, buyers, and investors. These expos and summits help firms stay updated on new machines, digital solutions, and automation systems.

International Manufacturing Technology Show (IMTS)

IMTS, held every two years in Chicago, is North America’s largest manufacturing and technology showcase. It gathers CNC machine builders, automation companies, and precision engineering experts from around the world. Georgia-based firms attend to explore new technologies, network with suppliers, and benchmark best practices.

The event features live machining demos, robotics showcases, and industrial software exhibits that set the direction for the next generation of manufacturing.

Georgia Manufacturing Summit

The Georgia Manufacturing Summit is a state-level annual event that focuses on local manufacturers, suppliers, and innovators. It provides a platform for education, networking, and industry recognition. CNC firms showcase their capabilities, meet OEM buyers, and participate in workshops on automation, workforce development, and export opportunities.

The summit emphasizes building stronger connections within Georgia’s manufacturing ecosystem, fostering collaboration across sectors.

Summary Table of Events

| Event | Frequency | Location / Host | Highlights |

|---|---|---|---|

| International Manufacturing Technology Show (IMTS) | Biennial | Chicago, IL, USA | Machine demos, robotics, digital solutions |

| Georgia Manufacturing Summit | Annual | Atlanta, GA, USA | State manufacturing showcase, networking |

Part 4: Impact of Global Trade Policies

Global trade policies have a strong influence on Georgia’s CNC machining industry. The state’s economy is globally connected through ports, logistics hubs, and export-oriented industries. Import tariffs, material costs, and export restrictions can directly affect CNC operations, especially those relying on imported alloys, tools, and machine components.

Georgia’s Port of Savannah gives local manufacturers an advantage in accessing overseas suppliers. However, trade tensions or shipping disruptions can increase lead times and costs. To offset these risks, many Georgia CNC firms are localizing their supply chains and developing partnerships with regional material suppliers.

Global reshoring and supply chain diversification are driving more OEMs to choose domestic suppliers, benefiting Georgia-based CNC shops. To stay competitive internationally, firms continue to focus on certifications, automation, and sustainability. Meeting ISO, AS9100, and ITAR requirements allows Georgia companies to serve high-value global markets such as aerospace and defense.

Environmental regulations and sustainability goals also shape production. Many CNC firms are investing in energy-efficient machines, coolant recycling, and digital monitoring systems to reduce waste and improve productivity.

Part 5: Conclusion

Georgia stands out as a fast-growing hub for precision machining in the southeastern United States. With advanced infrastructure, supportive government programs, and skilled talent pipelines, the state is well positioned to lead in next-generation CNC manufacturing.

Opportunities exist in aerospace, automotive, energy, and medical devices, while challenges include rising labor costs, material supply volatility, and competition for skilled machinists. However, by embracing automation, innovation, and sustainability, Georgia’s CNC shops can continue to expand their capacity and global reach.

In the coming decade, Georgia’s CNC machining industry will play a central role in strengthening domestic supply chains and enabling advanced manufacturing, making it one of the most promising industrial regions in North America.

Recommended Reading:

- CNC Machining Malta: Manufacturers & Industry Guide

- CNC Machining Cape Verde: Manufacturers & Industry Guide

- CNC Machining Suriname: Manufacturers & Industry Guide

- CNC Machining Myanmar: Manufacturers & Industry Guide

- CNC Machining Mali: Manufacturers & Industry Guide

- CNC Machining Equatorial Guinea: Manufacturers & Industry Guide

- CNC Machining Guinea-Bissau: Manufacturers & Industry Guide

- CNC Machining Brunei: Manufacturers & Industry Guide

Is Aluminum Magnetic?

Thermal Break Aluminium Window Profile Manufacturer

2020 Aluminum Extrusion T Slot Aluminum Extrusion

Aluminium Square Tube Extrusion Profile With 6063 T5 Alloy Anodized Extruded Aluminium Profile