What is Cast Aluminium vs CNC aluminium?

Navigating the complexities of aluminum manufacturing can be daunting. Understanding the distinctions between cast aluminum and CNC aluminum is essential for making informed decisions in your projects.

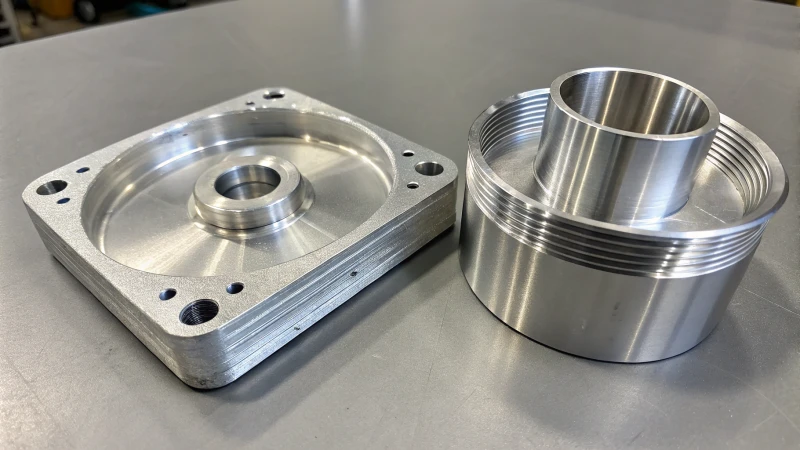

Cast aluminum is produced by pouring molten aluminum into molds, making it ideal for large, complex shapes in high volumes. CNC aluminum involves machining solid blocks of aluminum for high precision and smooth finishes. Each method has its advantages based on application and production needs.

This guide delves deeper into the characteristics of each process, providing valuable insights that could influence your next manufacturing decision.

What are the advantages of cast aluminum over CNC aluminum?

Exploring the advantages of cast aluminum reveals distinct benefits over CNC aluminum in various manufacturing contexts.

Cast aluminum is more cost-effective for large production runs, offers superior design flexibility for complex shapes, and provides adequate strength for many applications compared to CNC machined aluminum.

Cost-Effectiveness in Large Volumes

One of the primary advantages of cast aluminum is its cost-effectiveness for large production runs. The initial investment in molds can be significant, but once they are created, they can be reused for multiple parts, significantly reducing the cost per unit. This makes cast aluminum particularly appealing for industries that require mass production, such as automotive and aerospace.

For example, a company manufacturing engine blocks or wheels can utilize casting to produce thousands of units with minimal incremental cost. This contrasts sharply with CNC aluminum, which incurs higher costs due to the material waste produced during machining.

Design Flexibility and Complexity

Cast aluminum excels when it comes to complex geometries. The casting process allows manufacturers to create intricate shapes that would be challenging or impossible to achieve through CNC machining. This capability is crucial for applications requiring hollow sections or detailed features, like those found in consumer electronics housings.

| Here’s a comparison of the complexity achievable with each method: | Feature | Cast Aluminum | CNC Aluminum |

|---|---|---|---|

| Complex Shapes | Easily produces complex and intricate designs | Limited to simpler shapes; may require secondary ops | |

| Hollow Sections | Ideal for creating parts with hollow cavities | Difficult to achieve without additional processes | |

| Thin Walls | Capable of producing components with thin walls | Less effective; risks structural integrity |

Surface Finish Considerations

While cast aluminum typically has a rougher surface finish compared to CNC aluminum, it can still be treated post-production to enhance aesthetics. Techniques like grinding or coating can be applied to improve the surface quality of cast parts, making them suitable for consumer-facing products. This adaptability allows designers more freedom in their choices.

CNC aluminum, on the other hand, provides a high-quality surface finish straight from the machining process. However, for applications where the ultimate appearance is less critical, cast aluminum’s rougher finish may be perfectly acceptable and significantly more economical.

Mechanical Properties and Strength

In terms of strength, while CNC aluminum generally offers more uniform mechanical properties due to its solid block origins, cast aluminum can still provide adequate strength for many applications. It’s important to note that advances in casting techniques have improved the consistency and reliability of cast parts.

For example:

- Die Casting can yield parts with considerable strength and durability.

- Sand Casting, while less precise, is often sufficient for non-critical applications.

In scenarios where intricate shapes are required, the strength-to-weight ratio of cast aluminum often meets industry standards without necessitating additional machining processes.

Conclusion**

In summary, cast aluminum offers numerous advantages over CNC aluminum, particularly in terms of cost-effectiveness, design flexibility, and suitability for large production volumes. For industries where complexity and large quantities are paramount, cast aluminum remains a go-to choice. To explore more about how these materials can impact your projects, check out these resources: cost-effective casting, design advantages of casting, understanding mechanical properties.

How does the cost of production compare between cast and CNC aluminum?

Exploring the cost differences between cast and CNC aluminum reveals insights into efficiency and suitability for various projects. Let’s break down the factors that influence production expenses.

The cost of production between cast and CNC aluminum varies greatly depending on factors like volume, precision requirements, and material waste. Cast aluminum tends to be more economical for large volumes, while CNC machining is ideal for precision and smaller runs.

Comparing Cost Structures

When comparing the costs associated with cast and CNC aluminum production, it’s essential to look at several factors that contribute to the overall expenses.

-

Initial Setup Costs

-

Cast Aluminum:

- The initial investment can be substantial due to the need for creating molds. However, once the mold is made, it can be used for a large number of parts, making it cost-effective for high-volume production.

- Mold design considerations are crucial in determining the initial setup costs.

-

CNC Aluminum:

- The costs for CNC machining are typically lower for small production runs since there are no molds to create. The CNC machine setup is flexible, allowing for quick changes in design without significant additional costs.

-

-

Material Efficiency

-

Cast Aluminum:

- This method generates minimal waste since the molten aluminum fills the mold completely, resulting in efficient use of material.

-

CNC Aluminum:

- There is a higher material waste due to the subtractive nature of the machining process, where excess aluminum is cut away. This can lead to increased costs, particularly when producing larger parts.

-

Cost Per Unit Analysis

The cost per unit can greatly vary between these two processes based on the production scale and complexity. Below is a simplified comparison:

| Aspect | Cast Aluminum | CNC Aluminum |

|---|---|---|

| Setup Costs | High (due to mold creation) | Low (no molds needed) |

| Material Waste | Low (efficient use of molten aluminum) | High (material removed during machining) |

| Volume Efficiency | Cost-effective for large volumes | Better for low to medium volumes |

| Unit Cost (High Volume) | Generally lower due to mold reuse | Generally higher due to material waste |

| Unit Cost (Low Volume) | Higher initial costs but cheaper per unit in bulk | Higher cost per part |

Production Flexibility

Flexibility in production is another key factor affecting costs:

- Cast Aluminum:

- Once a mold is made, any changes to the part design often require new molds, leading to additional costs and time delays. This rigidity can be a disadvantage if design changes are frequent.

- CNC Aluminum:

- Offers higher flexibility as adjustments can be made quickly without significant retooling. This is particularly beneficial for projects requiring rapid prototyping or customization.

Conclusion on Costs

Understanding the cost differences between cast and CNC aluminum production methods is critical for informed decision-making in manufacturing. Each method has its own set of advantages and disadvantages based on the production needs, which can significantly impact overall costs.

Which manufacturing method is better for high-volume production?

When it comes to high-volume production, selecting the right manufacturing method is crucial. But which method truly stands out?

For high-volume production, casting often proves more cost-effective due to lower unit costs after initial mold creation. However, if precision and surface finish are paramount, CNC machining may be the better choice despite higher costs.

Understanding High-Volume Production

High-volume production refers to the manufacturing of large quantities of products in a cost-effective manner. This often necessitates the use of specialized manufacturing methods that can efficiently produce consistent quality at scale. The choice of method can significantly impact both production costs and product quality.

Key Manufacturing Methods for High Volume

When considering manufacturing methods for high-volume production, two prominent techniques often come into play:

- Casting

- CNC Machining

Each method offers unique advantages and drawbacks, which can affect their suitability for different applications.

1. Casting for High-Volume Production

Casting methods, such as die casting or sand casting, can be particularly effective for high-volume production due to:

- Cost Efficiency: Once the initial mold is created, producing additional units becomes relatively inexpensive.

- Complex Shapes: Casting allows for intricate designs that would be challenging to achieve through machining.

| Advantages of Casting | Drawbacks of Casting |

|---|---|

| Cost-effective for large quantities | May require secondary operations |

| Capable of producing complex geometries | Variable strength and surface finish |

| Lower material waste | Less precise than CNC machining |

2. CNC Machining for High-Volume Production

CNC machining is another viable option, particularly when precision is critical:

- Precision and Consistency: CNC machining can achieve tight tolerances and high-quality surface finishes, making it ideal for applications requiring exact specifications.

- Material Integrity: Parts produced through CNC tend to have uniform mechanical properties due to being cut from solid blocks of material.

| Advantages of CNC Machining | Drawbacks of CNC Machining |

|---|---|

| High precision and tight tolerances | Higher material waste due to cutting |

| Consistent quality across parts | More expensive per unit for large volumes |

| Ideal for small batch runs | Slower production rates compared to casting |

Choosing the Right Method

The decision on which manufacturing method to use often comes down to specific project requirements:

- If your project involves producing a large number of parts that are complex in shape but do not require extreme precision, casting might be the best option.

- Conversely, if your project requires high precision and consistency, CNC machining could be more suitable despite the potential higher costs.

Factors to Consider

When evaluating manufacturing methods, consider:

- Volume Needs: What quantity do you need?

- Budget Constraints: How much are you willing to spend?

- Quality Requirements: What level of precision and finish is necessary?

- Material Properties: Are there specific material qualities required?

By carefully analyzing these factors, you can select the manufacturing method that aligns best with your goals for high-volume production.

What are the environmental impacts of cast aluminum versus CNC aluminum?

Understanding the environmental impacts of cast aluminum versus CNC aluminum is crucial for sustainable manufacturing choices. Let’s explore their differences in energy consumption, waste generation, recycling potential, and more.

The environmental impacts of cast aluminum compared to CNC aluminum include differences in energy consumption, material waste generation, recycling potential, and water usage. Understanding these factors helps in making sustainable material choices.

Energy Consumption and Emissions

When examining the environmental impacts of cast aluminum versus CNC aluminum, one key factor to consider is the energy consumption associated with each process. Cast aluminum typically requires high energy inputs for melting the metal and maintaining the temperature during the casting process.

In contrast, CNC machining uses energy primarily for operating the machines. While both methods consume significant energy, CNC processes can sometimes be more efficient, especially in shorter production runs. For further exploration of this topic, check out energy efficiency in manufacturing.

Material Waste Generation

Material waste is another critical environmental aspect.

- Cast Aluminum: This method generates minimal waste since the mold is designed to use nearly all of the molten aluminum poured into it, with only excess metal being discarded.

- CNC Aluminum: Conversely, CNC machining involves cutting away material from solid blocks, which can lead to higher waste levels. This waste not only includes the removed aluminum but also the byproducts generated during the machining process.

| Process Type | Material Waste Generation |

|---|---|

| Cast Aluminum | Low (only excess from molds) |

| CNC Aluminum | High (material removed during machining) |

For insights on reducing waste in manufacturing, see waste management strategies.

Recycling Potential

Both cast and CNC aluminum have excellent recycling potential, making them eco-friendly options in terms of material lifecycle. However, there are differences in how each type can be recycled:

- Cast Aluminum: Often recycled using a process that melts down the entire component, allowing for easy remolding into new products.

- CNC Aluminum: The scrap metal generated from CNC operations can also be recycled, but it often requires additional processing to ensure it meets the quality standards for reuse.

A study on aluminum recycling benefits highlights how recycling can mitigate environmental impacts significantly.

Water Usage

The water usage in manufacturing processes is an essential aspect of environmental impact assessments. In general, CNC machining tends to require more water for cooling and lubricating tools compared to cast aluminum processes, which typically require less water overall.

| Process Type | Water Usage |

|---|---|

| Cast Aluminum | Low |

| CNC Aluminum | Moderate to High |

For detailed insights on water conservation practices in manufacturing, check water efficiency tips.

Conclusion on Sustainability Considerations

Ultimately, the choice between cast aluminum and CNC aluminum should consider various factors such as energy consumption, material waste, recycling potential, and water usage. Each method has its unique environmental footprint that can influence decision-making in manufacturing and product design. Understanding these differences is crucial for making sustainable choices that align with your company’s values and goals.

How do design considerations influence the choice between cast and CNC aluminum?

Design considerations significantly impact the choice between cast and CNC aluminum methods. Understanding complexity, volume, precision, cost, and sustainability can guide your decision-making process effectively.

Design considerations like complexity, production volume, precision requirements, and cost implications greatly influence the choice between cast and CNC aluminum manufacturing methods. Understanding these factors ensures optimal decision-making for project specifications.

Understanding Design Requirements

Design considerations play a pivotal role in determining whether to opt for cast aluminum or CNC aluminum. Factors like complexity, precision, and volume directly influence this choice.

For instance, if a design requires intricate geometries or hollow sections, casting may be the preferred method due to its ability to create complex shapes without significant constraints. However, for designs demanding tight tolerances, CNC machining is often essential.

Consider the following aspects:

- Complex Geometries: Cast aluminum excels in producing shapes that are difficult to achieve through machining. This makes it ideal for applications like automotive components where design intricacy is crucial.

- Precision Needs: CNC machining is designed for high accuracy, making it suitable for industries such as aerospace, where precise specifications are mandatory.

Production Volume Considerations

Another critical design consideration is production volume. The choice between casting and CNC machining can be significantly influenced by the expected number of parts to be produced.

| Production Volume | Cast Aluminum | CNC Aluminum |

|---|---|---|

| High Volume | More cost-effective due to reusable molds. | Higher cost per unit but suitable for small batches. |

| Low Volume | Initial mold costs can be prohibitive. | Economical for custom or lower volume runs. |

When producing parts in large quantities, cast aluminum’s lower per-unit cost becomes a significant advantage, particularly when a consistent design can be maintained across multiple units.

Material Properties and Performance

The physical properties of the material also affect the decision-making process in design considerations. Different applications require different strengths, durability, and weight considerations.

- Strength and Durability: CNC aluminum typically offers greater strength due to its uniform material structure, which is essential for high-stress applications like medical devices.

- Weight Considerations: Lightweight designs are often necessary in industries like aerospace. Here, the choice may lean towards cast aluminum if it provides sufficient strength without adding unnecessary weight.

Cost Implications

Cost is always a crucial factor in manufacturing decisions. The initial costs of setting up molds for casting can be offset by the savings in mass production.

- Upfront Costs: Casting requires investment in mold creation, which can be expensive, particularly for complex designs.

- Operational Costs: CNC machining involves material waste, leading to increased costs per part, especially for larger components where a significant amount of material is removed.

Evaluating these factors helps designers make informed decisions on the manufacturing method that aligns with their project’s budget constraints.

Environmental Considerations

Sustainability is becoming increasingly important in product design and manufacturing. The environmental impact of each method should also be considered in the design phase.

- Material Waste: CNC machining generates more waste compared to casting. Thus, for designs that aim for lower environmental impact, casting may be preferable.

- Energy Consumption: Both methods have varying energy requirements, which could influence sustainability metrics during the design phase.

By balancing these design considerations against practical constraints and environmental impacts, manufacturers can better decide between cast and CNC aluminum based on their specific needs and goals.

Conclusion

Explore the distinctions between cast aluminum and CNC aluminum, focusing on manufacturing processes, cost-effectiveness, design flexibility, and environmental impacts for informed production decisions.