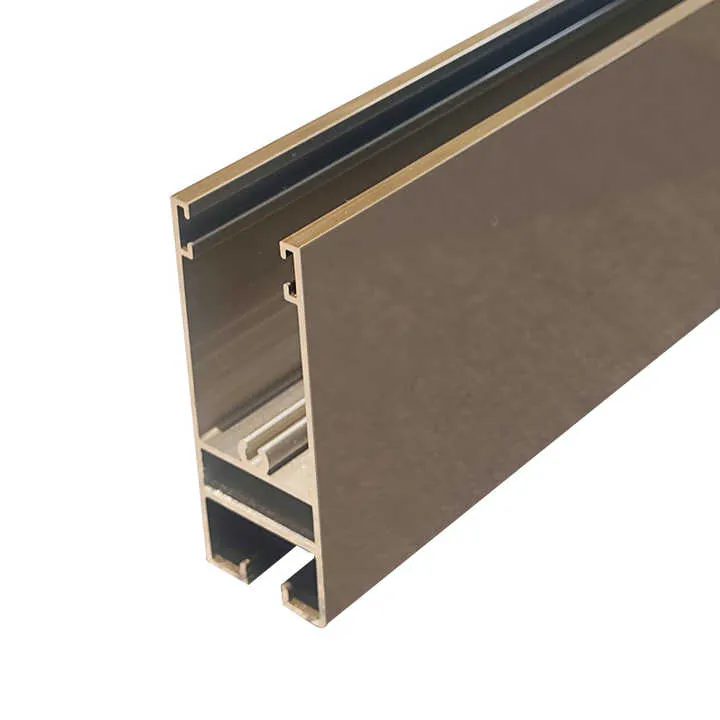

Съвместимост на алуминиевата екструзия с лазерно рязане?

Laser cutting looks clean and fast, but many buyers hesitate when aluminum extrusions are involved. Concerns about reflection, burrs, and edge quality often stop projects early. This doubt creates delays and extra cost.

Aluminum extrusions are compatible with laser cutting when thickness, alloy, and process control are correctly selected. With the right setup, laser cutting delivers precise and repeatable results.

Once design teams understand the limits and advantages, laser cutting becomes a practical option instead of a risk.

Can aluminum extrusions be processed by laser cutting?

Many people still think laser cutting is only for steel. That view is outdated and leads to missed efficiency.

Aluminum extrusions can be laser cut, but they require specific laser types, parameters, and experience.

Why aluminum is different

Aluminum reflects laser energy more than steel. It also conducts heat fast. These two traits change how cutting works.

Key challenges include:

- High reflectivity at some wavelengths

- Fast heat dissipation

- Risk of back reflection to optics

Modern fiber lasers handle these issues better than older systems.

Suitable laser technologies

Not all lasers perform the same on aluminum.

Common options:

- Fiber laser

- CO2 laser

Fiber lasers are now preferred. They offer:

- Higher efficiency

- Better absorption

- Faster cutting speeds

CO2 lasers can cut aluminum, but with more limits on thickness and speed.

Typical extrusion applications

Laser cutting is often used for:

- Slotting and holes

- End trimming

- Window openings

- Profile modification

It works well when cuts are 2D and accessible.

Accuracy and repeatability

Laser cutting delivers tight tolerances.

Ползите включват:

- Clean edges

- Minimal tool wear

- Digital repeatability

This supports automation and batch production.

Compatibility overview

| Фактор | Laser cutting suitability |

|---|---|

| Simple holes | Много добър |

| Complex shapes | Добър |

| Thick sections | Ограничен |

| Internal cavities | Not accessible |

Laser cutting is compatible, but not universal.

Aluminum extrusions can be processed using modern laser cutting systems.Истински

Fiber lasers allow effective cutting of aluminum with proper settings.

Laser cutting cannot be used on aluminum extrusions at all.Фалшив

With correct equipment, aluminum extrusions can be laser cut successfully.

How do thickness and alloy impact laser cut quality?

Thickness and alloy choice often decide success or failure. Ignoring them causes rough edges and slow cycles.

Laser cut quality on aluminum extrusions strongly depends on wall thickness and alloy composition.

Effect of thickness

Thicker aluminum needs more energy.

As thickness increases:

- Cutting speed drops

- Edge roughness increases

- Dross risk rises

Thin walls cut cleanly. Thick sections need careful tuning.

Typical practical ranges:

- Under 3 mm: very good quality

- 3 to 6 mm: acceptable with tuning

- Above 6 mm: challenging

Alloy composition matters

Different alloys react differently to heat.

Common extrusion alloys include:

- 6063

- 6061

- 6082

6063 cuts cleaner due to lower strength and smoother melt flow. Higher strength alloys resist cutting more.

Heat affected zone control

Laser cutting creates a narrow heat affected zone.

За алуминий:

- HAZ is small

- Mechanical properties change slightly

- Distortion is limited on thin profiles

This is better than many thermal methods.

Edge quality factors

Edge quality depends on:

- Laser power

- Focus position

- Assist gas

- Cutting speed

Nitrogen is often used to reduce oxidation.

Thickness and alloy comparison

| Параметър | Easier cutting | Harder cutting |

|---|---|---|

| Дебелина | Тънки стени | Дебели стени |

| Сплав | 6063 | 6082 |

| Сила | Долен | По-високо ниво |

| Heat flow | Умерен | Висока |

Designers should match design to process.

Thinner aluminum extrusion walls result in better laser cut edge quality.Истински

Less material allows cleaner and faster laser cutting.

All aluminum alloys behave the same during laser cutting.Фалшив

Different alloys show different absorption and melt behavior.

Is laser cutting preferred over mechanical methods?

Laser cutting looks modern, but it is not always the best choice. Mechanical methods still have value.

Laser cutting is preferred when precision, flexibility, and speed matter, but mechanical cutting suits heavy or simple tasks.

Advantages of laser cutting

Laser cutting offers:

- No physical tool contact

- High accuracy

- Easy program changes

- Clean cuts on thin profiles

It works well for custom or low-volume work.

Limits of laser cutting

Laser cutting struggles with:

- Very thick sections

- Deep internal cuts

- Highly reflective surfaces without control

Cost per hour can also be higher.

Mechanical cutting strengths

Механичните методи включват:

- Разпиляване

- Фрезоване

- Сондажи

- Punching

They handle:

- Thick aluminum

- High material removal

- Simple repetitive cuts

Tools wear, but results are stable.

Hybrid production approach

Many factories combine both methods.

Common practice:

- Laser for holes and slots

- Saw for length cutting

- CNC for precision faces

This balances cost and quality.

Method selection table

| Метод | Най-добър случай на употреба |

|---|---|

| Лазерно рязане | Thin, complex, flexible |

| Saw cutting | Straight cuts |

| CNC фрезоване | Висока прецизност |

| Punching | High volume sheets |

Preference depends on project goals.

Laser cutting offers higher flexibility than many mechanical cutting methods.Истински

Digital control allows quick design changes without new tooling.

Laser cutting always replaces mechanical cutting for aluminum extrusions.Фалшив

Mechanical methods remain better for some thickness and cost cases.

What safety precautions apply during laser cutting?

Laser cutting aluminum involves hidden risks. Ignoring safety leads to accidents and equipment damage.

Laser cutting aluminum extrusions requires strict safety controls for reflection, fumes, and fire risk.

Laser radiation safety

Lasers operate at high power.

Precautions include:

- Enclosed cutting systems

- Interlocked doors

- Protective eyewear

Operators must follow machine class rules.

Reflection and back reflection risk

Aluminum reflects laser light.

This can:

- Damage optics

- Create stray beams

Modern machines use sensors and coatings to manage this, but setup matters.

Fume and dust control

Laser cutting produces fumes.

Aluminum fumes are less toxic than some metals, but:

- Oxide particles form

- Fine dust accumulates

Extraction systems must run correctly.

Fire and spark management

Although aluminum does not burn easily, sparks can ignite nearby material.

Добрите практики включват:

- Clean work areas

- Fire detection systems

- Regular maintenance

Safety checklist

| Риск | Control method |

|---|---|

| Laser exposure | Enclosure and interlocks |

| Reflection | Proper settings |

| Fumes | Extraction systems |

| Fire | Clean workspace |

Safety protects both people and machines.

Laser cutting aluminum requires controls for reflection and fume extraction.Истински

Aluminum reflectivity and fumes create specific safety risks.

Laser cutting aluminum has no special safety concerns.Фалшив

High-power lasers and reflections require strict safety measures.

Заключение

Aluminum extrusions are compatible with laser cutting when design, alloy, and thickness are matched to the process. Laser cutting adds precision and flexibility, while safety and method choice ensure stable and cost-effective production.