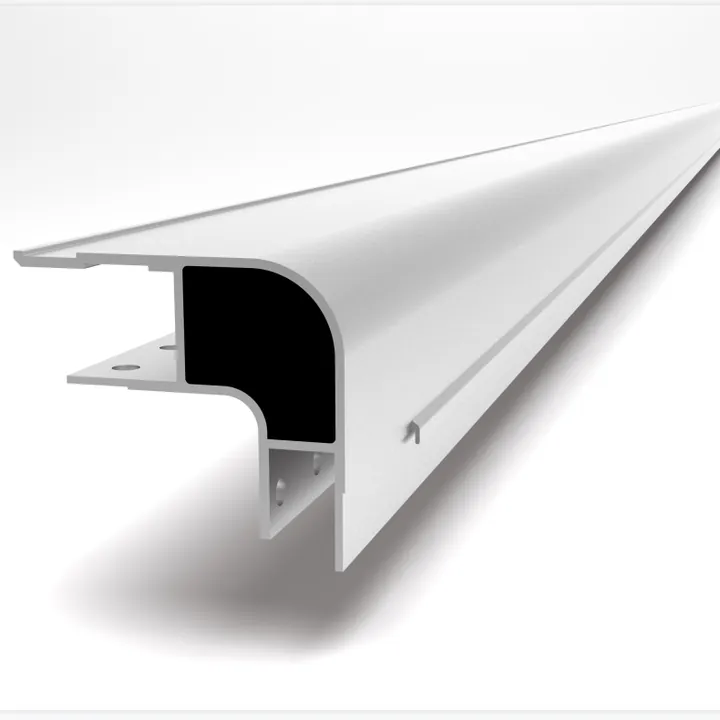

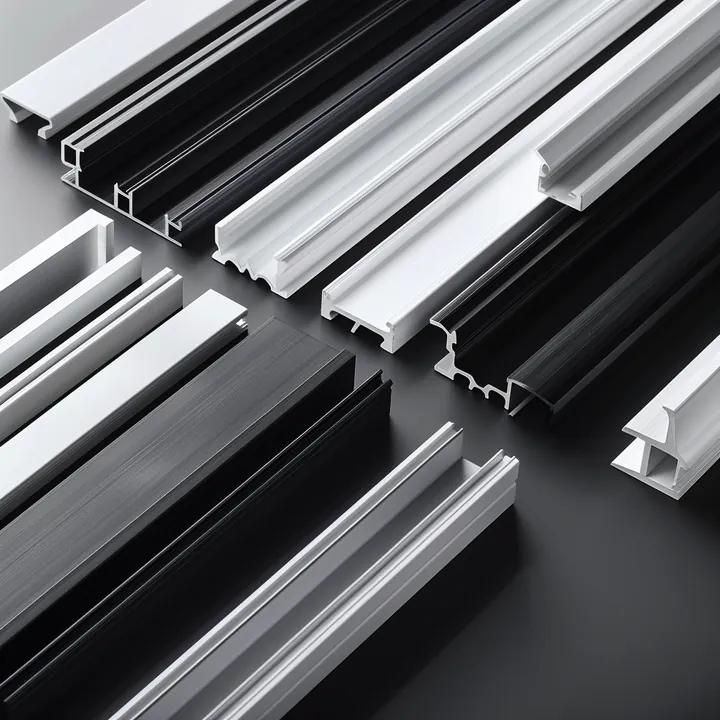

Налични цветове за покритие на алуминиеви екструдирани профили?

Color choice looks simple at first. Many buyers think it is just picking a shade from a chart. In reality, wrong assumptions about coating colors often cause rework, delays, and disputes.

Aluminum extrusion coating colors are widely available, but real availability depends on coating type, volume, consistency rules, and production control.

Once these limits are clear, color selection becomes predictable instead of risky.

What colors are commonly available for extrusion coatings?

Buyers often ask for a full rainbow. Suppliers often answer with a color chart. The truth sits in between.

The most commonly available extrusion coating colors are standard RAL shades, neutral tones, metallic finishes, and a small group of high-volume architectural colors.

These colors exist because they are stable, repeatable, and economical at scale.

Standard color families

Most coated aluminum extrusions fall into a few core color families.

- White and off-white tones

- Black and dark gray

- Silver and natural aluminum look

- Bronze and champagne

- Basic primary colors for signage or industrial use

These colors are popular because they hide small surface variations and remain stable across batches.

RAL system dominance

The RAL color system dominates powder coating for aluminum extrusions. Many coating lines keep a fixed inventory of high-demand RAL powders.

Common examples include:

- RAL 9016 (traffic white)

- RAL 9005 (jet black)

- RAL 7016 (anthracite gray)

- RAL 9006 and 9007 (aluminum silver shades)

These colors are widely available because:

- Demand is steady

- Powder suppliers stock them

- Coating lines run them frequently

This reduces setup time and cost.

Metallic and effect colors

Metallic finishes such as silver sparkle, matte metallic gray, or textured bronze are also common. They use special powder blends with metallic flakes or textures.

These finishes are popular in:

- Curtain wall systems

- Railings

- Мебели на открито

- Industrial enclosures

However, metallic effects require tighter control. Powder reuse is limited. This can affect cost and availability.

Industrial and safety colors

Some industries rely on strong colors for identification.

Examples include:

- Yellow for safety rails

- Red for emergency components

- Blue or green for machine frames

These colors are common but often produced on demand rather than kept on the line permanently.

Common availability overview

| Color group | Availability level | Cost stability |

|---|---|---|

| White, black, gray | Много висока | Very stable |

| Silver, champagne | Висока | Стабилен |

| Bronze tones | Среден | Стабилен |

| Bright primary colors | Среден | Умерен |

| Special effects | Долен | Променлива |

If a buyer stays inside these groups, color availability is rarely a problem.

Standard RAL colors like white, black, gray, and silver are widely available for aluminum extrusion coatings because they are high-volume and stable.Истински

These colors are commonly stocked and frequently run, which makes them easy to produce consistently.

All possible colors are equally available for aluminum extrusion coatings at the same cost.Фалшив

Availability and cost depend on demand, powder stock, setup needs, and coating type.

How is custom color matching achieved?

Custom color requests often sound simple. In practice, they require a structured process.

Custom color matching is achieved by developing or selecting a powder formulation that visually matches a reference under controlled lighting and agreed tolerance limits.

This process balances appearance, repeatability, and cost.

Common starting points for custom colors

Custom matching usually begins with one of these references:

- A physical color sample

- A Pantone code

- A non-standard RAL shade

- A finished product part

Among these, a physical coated aluminum sample gives the best result. Digital values alone are not enough.

The matching process step by step

1) Powder supplier proposes a formulation

2) Trial coating is applied to aluminum samples

3) Samples are cured under standard conditions

4) Color is checked under defined light sources

5) Adjustments are made if needed

6) Final sample is approved in writing

This process can take several days or weeks depending on accuracy needs.

Why lighting matters

Color perception changes under different light. A shade that looks perfect indoors may shift outdoors.

Professional matching checks color under:

- Daylight

- Fluorescent light

- Warm indoor light

Agreement on inspection light conditions is critical.

Tolerance instead of perfection

No industrial coating can guarantee zero color variation. Instead, suppliers work with tolerance limits.

Typical approaches include:

- Visual comparison against master sample

- Delta E value limits for instrument measurement

- Approved range rather than exact match

The tighter the tolerance, the higher the cost and rejection risk.

Cost impact of custom colors

Custom colors affect cost in several ways:

- Powder development or minimum order quantity

- Line cleaning and setup time

- Scrap during changeover

- Storage of leftover powder

For small volumes, custom colors can be expensive. For repeat large orders, cost becomes manageable.

Custom color feasibility table

| Фактор | Low impact | High impact |

|---|---|---|

| Order volume | Large batch | Small batch |

| Толерантност | Visual match | Instrument strict |

| Вид на завършека | Гладка | Metallic or texture |

| Repeat frequency | Ongoing | One-time |

Custom matching works best when the color will be used repeatedly.

Custom color matching relies on physical samples, controlled lighting, and agreed tolerances rather than digital color codes alone.Истински

Visual appearance on coated aluminum depends on curing, surface, and light, which digital values cannot fully define.

Once a custom color is approved, it can always be reproduced perfectly with no variation.Фалшив

Industrial coatings always allow small variation, which is managed through tolerance agreements rather than absolute matching.

Do certain finishes limit color options?

Finish type has a strong influence on color choice. This is often overlooked during design.

Yes, certain finishes limit color options because surface texture, transparency, and coating chemistry affect how color appears and how stable it is.

Understanding this avoids unrealistic expectations.

Powder coating finish types

Powder coating offers several surface finishes:

- Smooth matte

- Smooth gloss

- Текстуриран

- Metallic

- Sand or wrinkle effects

Each finish interacts with color differently.

Smooth finishes

Smooth matte and gloss finishes offer the widest color range. Most RAL and custom colors work here.

Gloss level affects perception:

- High gloss looks deeper and darker

- Matte looks softer and lighter

The same color code can appear different at different gloss levels.

Textured finishes

Textured finishes hide surface defects and are popular outdoors. However, they scatter light.

Effects include:

- Muted colors

- Reduced brightness

- Less sharp color definition

Very light or very dark colors work best with texture.

Metallic finishes

Metallic powders contain flakes. These flakes reflect light unevenly.

Limitations include:

- Limited color range

- Directional appearance

- Batch sensitivity

Metallic colors look premium, but matching across batches is harder.

Anodizing versus coating

Although this article focuses on coatings, many buyers compare anodizing and powder coating.

Анодиране:

- Relies on transparent oxide layers

- Shows base metal tone

- Limits color range

Powder coating:

- Covers surface fully

- Offers wider color freedom

If wide color choice is required, coating is usually preferred.

Finish and color compatibility overview

| Вид на завършека | Color flexibility | Uniformity risk |

|---|---|---|

| Smooth powder | Много висока | Нисък |

| Textured powder | Среден | Среден |

| Metallic powder | Долен | По-високо ниво |

| Transparent effects | Нисък | Висока |

Finish selection should happen before final color approval, not after.

Smooth powder coating finishes offer the widest range of color options for aluminum extrusions.Истински

Smooth finishes reflect light evenly and accept most standard and custom powder formulations.

All coating finishes support the same color range with identical appearance.Фалшив

Texture, metallic flakes, and transparency change how color appears and limit feasible options.

Is color uniformity guaranteed across large batches?

This is one of the most sensitive questions in coating projects. Many disputes start here.

Color uniformity across large batches is controlled and managed, but it is not absolute; it depends on process stability, batch control, and clear acceptance standards.

What uniformity really means

Uniformity does not mean every piece looks identical under all conditions. It means variation stays within agreed limits.

Sources of variation include:

- Powder lot differences

- Line temperature changes

- Curing time

- Profile wall thickness

- Hanging orientation

Even small shifts can affect appearance.

How suppliers control uniformity

Professional coating lines use several controls:

- Same powder batch for large orders

- Fixed line settings

- Process records for repeat orders

- Sample retention for reference

Large projects are often split into controlled lots with traceability.

Batch size matters

Uniformity is easier within one continuous run. When orders are split over weeks or months, variation risk increases.

Buyers who need strict uniformity often:

- Place larger single orders

- Approve control samples

- Accept slightly wider tolerance

Communication reduces risk

Clear agreement prevents conflict.

Key points to define:

- Approved master sample

- Inspection lighting condition

- Acceptance method

- Handling of future repeat orders

Without this, both sides rely on assumptions.

Practical expectation setting

In practice:

- Standard colors on smooth finishes achieve high uniformity

- Custom metallic colors carry higher variation risk

- Long-term repeat orders need periodic re-approval

Uniformity is a management task, not a promise.

Uniformity risk factors

| Фактор | Нисък риск | Висок риск |

|---|---|---|

| Color type | Standard RAL | Custom metallic |

| Завършете | Гладка | Текстуриран |

| Order timing | Single run | Split batches |

| Толерантност | Visual | Very tight |

When these factors are aligned, results are stable.

Color uniformity in large aluminum extrusion coating batches depends on process control and agreed tolerances rather than absolute sameness.Истински

Industrial coating processes manage variation within limits, not perfect identity.

Suppliers can guarantee zero color variation across unlimited production batches.Фалшив

Process variation always exists, and uniformity is controlled through standards and communication, not absolute guarantees.

Заключение

Aluminum extrusion coating colors are widely available, but not unlimited. Standard colors offer stability, custom colors require structure, finishes affect options, and uniformity depends on control. Clear expectations turn color from a risk into a reliable design choice.