CNC Machining Libya: Manufacturers & Industry Guide

الجزء 1: حجم السوق ونموه

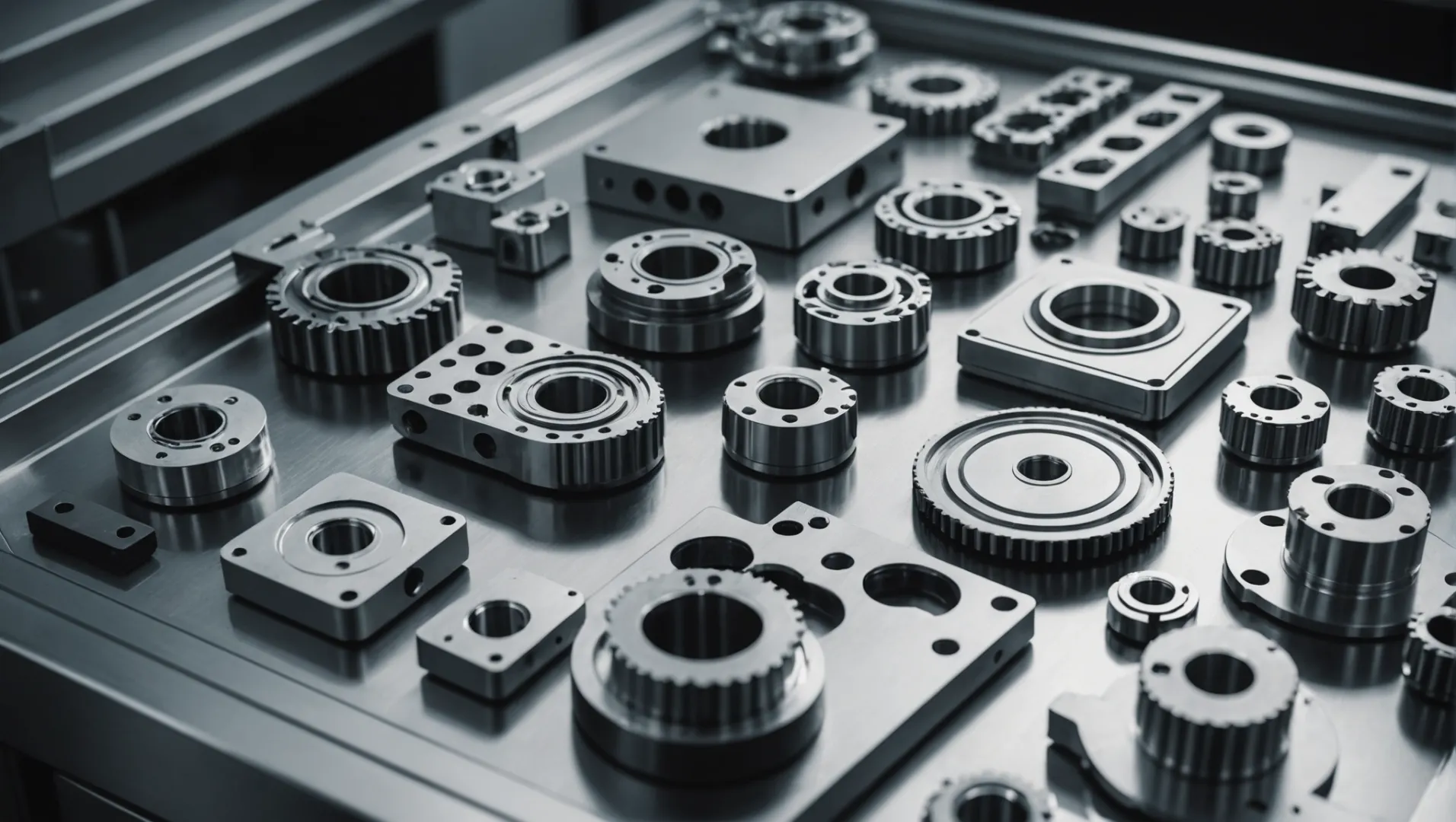

Libya’s manufacturing sector is still rebuilding after years of disruption, yet industrial activity is gradually returning in areas such as energy, construction, and repair services. Among the technologies driving this recovery is التصنيع الآلي باستخدام الحاسب الآلي, which provides the precision and efficiency needed for modern production.

CNC (Computer Numerical Control) systems enable the production of custom metal and plastic components used in pumps, valves, engines, and industrial assemblies. In cities like Tripoli, Benghazi, and Misrata, workshops are beginning to adopt these technologies for small-scale manufacturing and maintenance. The oil and gas sector, in particular, relies heavily on local machining capability for component repair and replacement.

The market remains modest, but demand is steady. CNC machining plays a vital role in keeping critical industries running, especially when imported spare parts are delayed. The expansion of industrial zones, improved logistics, and increased vocational training are helping new workshops enter the field. As stability improves, the combination of energy wealth and skilled labor could make Libya a regional player in precision engineering.

الجزء 2: الشركات الرائدة

Despite limited industrial infrastructure, several workshops and service firms are making strides in CNC machining and precision metalworking. Below are representative examples of companies shaping Libya’s machining capabilities.

Al-Naseem Engineering Workshop

اتصل بنا الآن

Located in Tripoli, Al-Naseem Engineering Workshop provides CNC turning, milling, and repair services for the oil and construction industries.

The company specializes in shafts, couplings, and pump components, as well as reverse engineering of worn parts. By combining CNC machines with traditional metalworking, Al-Naseem can meet both repair and small batch production needs. Their workshop also offers welding, surface finishing, and dynamic balancing. Their key advantage lies in fast turnaround times and local accessibility, which reduces costly import delays for clients.

Misrata Industrial Engineering

اتصل بنا الآن

Misrata Industrial Engineering operates a precision workshop serving manufacturing and maritime clients.

Their services include CNC milling, drilling, and fabrication of complex parts. The company supports the steel, ship repair, and machinery industries with reliable machining and technical support. By integrating CAD/CAM design and CNC operations, they can achieve high repeatability in complex components. Misrata Industrial Engineering is known for its role in heavy maintenance projects and its focus on quality assurance.

LibyaTech Manufacturing Solutions

اتصل بنا الآن

LibyaTech Manufacturing Solutions represents a new generation of CNC-oriented startups in Benghazi.

It provides precision machining, sheet metal cutting, and mechanical design services. The firm supports projects in energy, infrastructure, and research, offering rapid prototyping and small-run production. LibyaTech emphasizes the use of modern CNC controllers and simulation software, bringing digital manufacturing practices to local clients. Their strategy centers on high quality and technology-driven productivity.

Al-Jazeera Metal Works

اتصل بنا الآن

Al-Jazeera Metal Works, based in Sabha, is a southern Libyan company offering turning, milling, and welding for heavy equipment maintenance.

Its technicians handle industrial repairs for mining, agricultural, and transport machinery. The company operates a small CNC section for precision fitting and custom part creation. Their local presence in an underserved region makes them a critical support partner for regional industries that lack easy access to spare parts. Their strengths include mechanical versatility and adaptive solutions for field repairs.

Tripoli Mechanical Industries

اتصل بنا الآن

Tripoli Mechanical Industries is a general engineering firm providing machining, fabrication, and maintenance services for oilfield equipment.

The company’s capabilities include CNC and manual machining, welding, assembly, and inspection. It produces mechanical components such as housings, gears, and couplings. Their engineering team supports both new part production and refurbishment of used equipment. The workshop’s focus on reliability, coupled with decades of industrial experience, makes it a trusted supplier for many Libyan companies.

| الشركة | تأسست | Core Services | الصناعات المخدومة | نقاط القوة |

|---|---|---|---|---|

| Al-Naseem Engineering Workshop | 2000s | CNC turning, milling, repair | Oil & gas, construction | Fast local production, reliability |

| Misrata Industrial Engineering | 1990s | CNC milling, drilling, fabrication | Steel, ship repair, manufacturing | CAD/CAM integration, quality control |

| LibyaTech Manufacturing Solutions | 2010s | CNC machining, design, prototyping | Energy, R&D, infrastructure | Modern tech adoption, digital workflow |

| Al-Jazeera Metal Works | 2000s | Turning, welding, heavy repair | Mining, transport, agriculture | Field repair, regional accessibility |

| Tripoli Mechanical Industries | 1980s | Machining, assembly, inspection | Oilfield, industrial | Experience, consistent service |

الجزء 3: المعارض التجارية والفعاليات الصناعية

Libya Build Exhibition

Libya Build is the country’s largest construction and industrial technology event.

While primarily focused on construction and materials, the exhibition increasingly features machine tool suppliers, fabrication services, and CNC workshops. It provides local engineers with exposure to modern machining equipment and manufacturing solutions. CNC firms use the event to showcase products and establish partnerships with builders, contractors, and industrial service providers.

Libya Oil & Gas Exhibition

This event highlights Libya’s energy and engineering sectors, drawing companies from across North Africa and the Middle East.

For CNC machining companies, the show offers opportunities to meet oilfield service firms and equipment suppliers. Workshops can demonstrate their role in maintenance and production of critical parts for the petroleum industry. The exhibition also promotes technology transfer and investment in local fabrication capacity.

| الحدث | التردد | الموقع | أبرز الملامح |

|---|---|---|---|

| Libya Build Exhibition | سنوي | طرابلس | Construction tech, fabrication, CNC innovation |

| Libya Oil & Gas Exhibition | سنوي | Tripoli / Benghazi | Energy sector networking, maintenance, tooling |

Part 4: Impact of Trade Policies & Industrial Conditions

Libya’s CNC machining industry operates within a complex trade and industrial landscape.

Most CNC machines, spare parts, and cutting tools are imported, often through intermediaries in Europe, Turkey, or the United Arab Emirates. Trade policy fluctuations, customs regulations, and currency challenges affect both cost and delivery time. Local workshops mitigate these issues by stockpiling consumables or relying on regional distributors.

Energy supply is both an advantage and a challenge. Libya’s abundant oil reserves provide access to fuel, but power interruptions and infrastructure gaps can slow production. Many workshops rely on independent generators or solar-assisted backup systems to maintain consistent CNC operation.

The shortage of skilled machinists and CNC programmers remains another barrier. While mechanical knowledge is strong, digital manufacturing expertise is still developing. Universities and technical institutes are expanding vocational programs, often supported by private workshops through apprenticeship models. Training the next generation of machinists is key to sustaining growth in precision manufacturing.

Regional integration may help offset domestic constraints. Partnerships with Tunisian, Egyptian, and Turkish firms can bring equipment, expertise, and investment. These relationships could establish Libya as a key maintenance and fabrication center for North Africa. If trade routes stabilize, CNC machining may become one of the country’s fastest-growing technical fields.

Local content policies are also pushing oil and gas companies to rely more on domestic workshops. As a result, firms with CNC capability have a clear competitive advantage, offering shorter turnaround times and localized engineering support. The challenge ahead is to scale these operations while maintaining quality and efficiency.

الجزء 5: الخاتمة

CNC machining in Libya stands at the crossroads of opportunity and recovery. From Al-Naseem Engineering Workshop و Misrata Industrial Engineering to newer firms like LibyaTech Manufacturing Solutions, local companies are proving that precision technology can thrive even in a rebuilding economy. These workshops keep vital industries running-repairing, manufacturing, and innovating despite limited infrastructure.

To achieve broader industrial transformation, Libya must continue investing in technical education, equipment modernization, and trade facilitation. Creating industrial clusters, supporting machine tool imports, and standardizing quality systems will help the sector mature. Workshops that adopt automation, efficient workflow design, and quality certification will gain long-term advantages in both domestic and regional markets.

As Libya rebuilds its economy, CNC machining will play a critical role in restoring and modernizing its infrastructure. The blend of technical skill, resilience, and growing access to digital manufacturing tools suggests a promising future. In the next decade, Libya could evolve from a repair-based workshop economy to a regional hub for high-precision manufacturing and industrial engineering-powered by CNC technology and the determination of its local machinists.

القراءة الموصى بها::القراءة الموصى بها

- CNC Machining Guyana: Manufacturers & Industry Guide

- CNC Machining Seychelles: Manufacturers & Industry Guide

- CNC Machining Botswana: Manufacturers & Industry Guide

قوة الخضوع مقابل قوة الشد: لسبائك الألومنيوم؟

ضميمة بالوعة الحرارة المصنوعة من الألومنيوم

بالوعة حرارية من الألومنيوم الأسود المؤكسد للأجهزة

ملف صندوق إضاءة من الألومنيوم