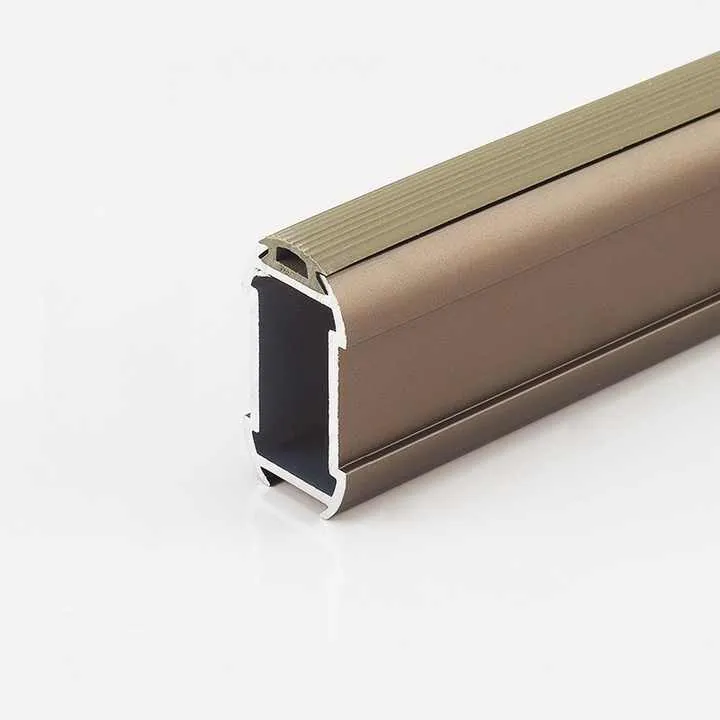

تقدير تكلفة تصنيع قضبان الألمنيوم المبثوقة؟

يشعر العديد من المشترين بعدم اليقين عند تلقي عروض الأسعار الخاصة بالتصنيع. تبدو الأرقام مرتفعة. تبدو التفسيرات غامضة. يصبح التحكم في التكاليف صعبًا دون وجود منطق واضح وراء التسعير.

تكلفة تصنيع قضبان الألمنيوم تعتمد على الوقت والتعقيد والإعداد والحجم. عندما يتم قياس هذه العناصر بوضوح، يصبح تقدير التكلفة قابلاً للتنبؤ والإدارة.

هذا الموضوع مهم لأن التصنيع غالبًا ما يكون أكبر متغير بعد البثق نفسه. يمكن أن يؤدي تغيير بسيط في التصميم أو قرار الطلب إلى تغيير التكلفة الإجمالية أكثر من تغيرات أسعار المعادن.

ما هي العوامل التي تؤثر على تكلفة تصنيع القوالب البلاستيكية؟

غالبًا ما تبدو تكاليف التصنيع غير متوقعة. فقد تحصل ملفات تعريف متشابهة على عروض أسعار مختلفة تمامًا. وهذا يثير الشكوك ويؤخر اتخاذ القرارات.

تتأثر تكلفة التصنيع بوقت تشغيل الماكينة، وجهد الإعداد، وتآكل الأدوات، ومهارة العمالة، ومتطلبات مراقبة الجودة.

كل عامل يضيف تكلفة بطريقة مختلفة. معًا، يحددون السعر النهائي للوحدة.

وقت تشغيل الماكينة باعتباره المحرك الأساسي للتكلفة

وقت تشغيل الماكينة هو العامل الأكبر. يتم احتساب تكلفة استخدام ماكينات الطحن والحفر باستخدام الحاسب الآلي بالساعة. فكلما طالت مدة بقاء القطعة على الماكينة، ارتفعت التكلفة.

قد يستغرق الحفر البسيط ثوانٍ معدودة. قد يستغرق الحفر المعقد دقائق. تزيد المعالجة متعددة الجوانب من وقت المعالجة.

جهود الإعداد والتحويل

يشمل الإعداد تركيب التجهيزات، وتحميل الأدوات، وإعداد البرنامج، وفحص المنتج الأول. تكلفة الإعداد ثابتة في الغالب لكل دفعة، وليس لكل قطعة.

تبدو الدفعات الصغيرة باهظة الثمن لأن تكلفة الإعداد موزعة على عدد أقل من الوحدات.

تآكل الأدوات واستبدالها

الألومنيوم مادة لينة، لكن المعالجة بسرعة عالية لا تزال تؤدي إلى تآكل الأدوات. القواطع ذات القطر الصغير تتآكل بشكل أسرع. الشقوق العميقة تزيد من خطر الكسر.

يتم تضمين تكلفة استبدال الأدوات في عروض أسعار التصنيع، خاصة بالنسبة للأعمال التي تتطلب دقة عالية.

المهارات العمالية والإشراف

تتطلب معالجة القذف مشغلين مهرة. يتطلب العمل الدقيق الإشراف والتفتيش. تزيد مستويات المهارة العالية من الأجور بالساعة.

كما أن النوبات الليلية والعمل الإضافي يزيدان من تكلفة العمالة.

متطلبات الجودة والتفتيش

تتطلب التفاوتات الأكثر دقة مزيدًا من الفحوصات. وتؤدي خطوات الفحص الإضافية إلى إبطاء الإنتاج. وهذا يرفع التكلفة دون تغيير المواد.

فيما يلي ملخص لأهم عوامل التكلفة.

| عامل التكلفة | مستوى تأثير التكلفة | نوع التكلفة |

|---|---|---|

| وقت الماكينة | عالية | متغير |

| الإعداد | متوسط | ثابت لكل دفعة |

| الأدوات | متوسط | متغير |

| العمالة | متوسط | متغير |

| الفحص | منخفضة إلى متوسطة | متغير |

وقت تشغيل الماكينة هو العامل الأكبر في تكلفة التصنيع.صحيح

تتناسب أسعار الآلات بالساعة بشكل مباشر مع وقت التشغيل.

تكلفة التصنيع تعتمد بشكل أساسي على سعر سبائك الألومنيوم.خطأ

تتحدد تكلفة التصنيع حسب وقت المعالجة والعمالة، وليس سعر المعدن.

كيف تؤثر ميزات التصميم على وقت المعالجة؟

غالبًا ما تؤثر الخيارات التصميمية التي يتم اتخاذها في مرحلة مبكرة على تكلفة التصنيع لاحقًا. تبدأ العديد من مشكلات التكلفة في مرحلة الرسم.

تؤثر ميزات التصميم بشكل مباشر على وقت المعالجة من خلال تغيير مسارات الأدوات وعدد العمليات وخطوات المناولة.

التفاصيل الصغيرة في التصميم يمكن أن تضاعف جهد التصنيع.

عدد الثقوب ونوعها

كل ثقب يضيف وقتًا. الثقوب المارة أسرع من الثقوب العمياء. الثقوب الملولبة تستغرق وقتًا أطول من الثقوب المحفورة.

تحتاج الثقوب العميقة إلى حفر نقر. وهذا يبطئ وقت الدورة.

الفتحات والجيوب والتجاويف

الفتحات المفتوحة أسهل من الجيوب المغلقة. الجيوب العميقة تتطلب عدة تمريرات. الجدران الرقيقة تزيد من الاهتزاز وتبطئ معدلات التغذية.

تتطلب الجيوب المعقدة في الغالب أدوات أصغر حجماً، والتي تقطع ببطء أكبر.

التفاوتات المسموح بها وتشطيب السطح

التفاوتات الدقيقة تقلل السرعة. يجب أن تعمل الآلات بسرعة أقل. يلزم إجراء المزيد من التمريرات.

متطلبات تشطيب السطح مهمة أيضًا. قد يحتاج التشطيب الناعم إلى عمليات تشطيب أو تلميع.

تصنيع متعدد الجوانب

تتطلب الملامح التي تتطلب معالجة على عدة أوجه إعادة وضعها. كل إعادة وضع تضيف وقتًا للإعداد والمحاذاة.

تصميمات تسمح بالتصنيع من جانب واحد مما يقلل التكلفة.

الطول وصعوبة المناولة

يصعب تثبيت القطع الطويلة. قد تحتاج إلى دعامات خاصة. وهذا يزيد من صعوبة الإعداد ويبطئ عملية التحميل.

فيما يلي مقارنة بين ميزات التصميم الشائعة.

| ميزة التصميم | تأثير وقت المعالجة |

|---|---|

| من خلال الثقوب | منخفضة |

| ثقوب مثقوبة | متوسط |

| جيوب عميقة | عالية |

| تفاوتات ضيقة | عالية |

| تصنيع متعدد الأوجه | عالية |

يمكن أن يؤدي تبسيط التصميم إلى تقليل وقت المعالجة بشكل كبير.صحيح

تقلل الميزات الأقل والتفاوتات الأقل من مسارات الأدوات والعمليات.

يظل وقت المعالجة كما هو بغض النظر عن مدى تعقيد التصميم.خطأ

تؤدي الميزات المعقدة إلى زيادة تغييرات الأدوات ووقت الدورة.

هل يمكن أن يقلل حجم الدفعة من تكلفة تصنيع الوحدة؟

غالبًا ما يركز المشترون على سعر الوحدة فقط. وهم يتجاهلون كيفية تأثير حجم الطلب على هيكل التكلفة.

تقلل الأحجام الكبيرة للدفعات من تكلفة تصنيع الوحدة عن طريق توزيع وقت الإعداد وتحسين كفاءة الماكينة.

حجم الدفعة يؤثر على التكلفة أكثر مما يتوقع الكثيرون.

توزيع تكاليف الإعداد

يتم تحديد وقت الإعداد لكل دفعة. سواء كان عدد القطع المطلوب تصنيعها 10 قطع أو 1000 قطعة، فإن وقت الإعداد يكون متشابهاً.

تخفف الدفعات الكبيرة من هذه التكلفة. أما الدفعات الصغيرة فتتحمل عبء إعداد ثقيل.

كفاءة عمر الأداة

في الدفعات الكبيرة، يتآكل الأدوات بشكل متوقع. يتم التخطيط لتغيير الأدوات. وهذا يحسن الكفاءة.

غالبًا ما تتوقف الدفعات الصغيرة قبل أن تصل الأدوات إلى مستوى تآكل مستقر، مما يؤدي إلى إهدار العمر الافتراضي المحتمل للأداة.

فوائد البرمجة والتحسين

تبرر الدفعات الكبيرة تحسين البرنامج. يتم ضبط معدلات التغذية بدقة. يتم تحسين مسارات الأدوات.

الطلبات الصغيرة نادراً ما تحظى بتحسينات كبيرة.

أولوية الجدولة

غالبًا ما تحظى الطلبات الكبيرة بالأولوية. وهذا يقلل من وقت التوقف بين العمليات. تعمل الآلات لفترة أطول دون توقف.

تؤدي التوقفات المتكررة إلى زيادة وقت التوقف عن العمل والتكلفة.

المفاضلة بين المخزون والتدفق النقدي

تقلل الدفعات الكبيرة من تكلفة الوحدة ولكنها تزيد من المخزون. يجب على المشترين الموازنة بين التخزين والتدفق النقدي مقابل وفورات التصنيع.

عادةً ما تؤدي الأحجام الكبيرة للدفعات إلى خفض تكلفة تصنيع الوحدة.صحيح

توزع تكاليف الإعداد والتحسين على عدد أكبر من الوحدات.

حجم الدفعة لا يؤثر على تكلفة التصنيع.خطأ

يؤثر حجم الدفعة بشكل كبير على تكلفة الإعداد لكل وحدة.

ما هي الأدوات المستخدمة لتقدير التكاليف؟

التقدير الدقيق للتكاليف يبني الثقة. التقديرات السيئة تؤدي إلى النزاعات والتأخير.

يستخدم تقدير تكلفة التصنيع حسابات قائمة على الوقت والبيانات التاريخية وأدوات برمجية للتنبؤ بتكلفة الوحدة.

كل أداة لها نقاط قوة وقيود.

التقدير على أساس الوقت

تقوم هذه الطريقة بتقدير وقت الدورة لكل عملية. يتم تطبيق معدل ساعة العمل للآلة. يتم إضافة وقت الإعداد.

هذا النهج شفاف ولكنه يتطلب خبرة.

التقدير القائم على الميزات

يتم حساب الميزات مثل الثقوب والفتحات والجيوب. لكل ميزة قيمة زمنية قياسية.

هذه الطريقة سريعة ولكنها أقل دقة بالنسبة للأجزاء المعقدة.

مقارنة البيانات التاريخية

يتم استخدام الأجزاء المماثلة السابقة كمرجع. يتم إجراء تعديلات حسب الحجم والتعقيد.

هذا يعمل بشكل جيد في بيئات الإنتاج المستقرة.

محاكاة برمجيات CAM

يحاكي برنامج CAM مسارات الأدوات ووقت الدورة. وهذا يعطي تقديرات زمنية مفصلة.

تعتمد الدقة على صحة المدخلات وبيانات الجهاز.

تكامل نظام عروض الأسعار

تجمع العديد من المتاجر بين الطرق المختلفة. يتم تحسين التقدير الأولي بعد محاكاة CAM. ويوازن العرض النهائي بين المخاطر والهامش.

فيما يلي مقارنة بين أدوات التقدير.

| أداة التقدير | مستوى الدقة | السرعة |

|---|---|---|

| الحساب على أساس الوقت | عالية | متوسط |

| قائم على الميزات | متوسط | عالية |

| البيانات التاريخية | متوسط | عالية |

| محاكاة CAM | عالية | منخفضة |

تحسن محاكاة CAM دقة تقدير تكلفة التصنيع.صحيح

يحسب مسارات الأدوات ووقت الدورة بالتفصيل.

يمكن تقدير تكلفة التصنيع بدقة دون الحاجة إلى أي بيانات عملية.خطأ

يتطلب التقدير الدقيق وقتًا أو ميزات أو بيانات تاريخية.

الخاتمة

يعتمد تقدير تكلفة تصنيع قضبان الألمنيوم على الفهم الواضح للوقت والتصميم وحجم الدفعة وأدوات التقدير. عندما تكون هذه العوامل واضحة، يتمكن المشترون من التحكم وتقليل المفاجآت واتخاذ قرارات أفضل بشأن التوريد.