تصنيف مقاومة الحريق لسبائك الألومنيوم؟

غالبًا ما تصبح السلامة من الحرائق مشكلة فقط بعد تصميم المشروع بالفعل. إن مقاطع الألومنيوم خفيفة وقوية، ولكن العديد من المشترين يشعرون بالقلق من مخاطر الحرائق. هذا القلق يمكن أن يبطئ من اتخاذ القرارات ويثير الشكوك.

لا يحترق الألومنيوم المبثوق في حد ذاته ولكن تصنيف مقاومته للحريق يعتمد على السبيكة والتصميم والمعالجة السطحية واستخدام النظام. يذوب الألومنيوم عند درجة حرارة عالية، لذا يجب تقييمه كجزء من نظام كامل مقاوم للحريق.

يتوقف العديد من المشترين عن القراءة بمجرد سماعهم عبارة “الألومنيوم يذوب”. وهذا خطأ. إن أداء الحرائق أكثر تعقيدًا، ويمكن أن يساعد فهمه في اتخاذ خيارات أفضل في التصميم والتوريد.

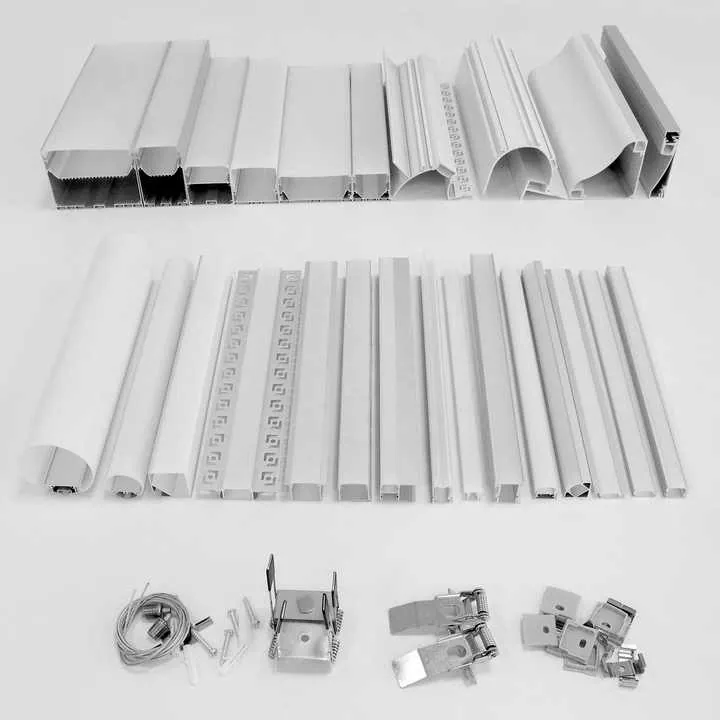

ما هي تصنيفات مقاومة الحريق الموجودة لهياكل الألومنيوم؟

غالباً ما تكون تصنيفات الحرائق مربكة لمشتري الألومنيوم. يتوقع الكثير من الناس رقمًا بسيطًا، ولكن لا يتم تصنيف هياكل الألومنيوم بنفس الطريقة التي يتم بها تصنيف الخرسانة أو الفولاذ.

عادةً لا تتمتع هياكل الألومنيوم عادةً بتصنيف مقاومة جوهرية للحريق. ينطبق التصنيف على التجميع الكامل، وليس على الألومنيوم المبثوق وحده.

سلوك الألومنيوم في النار

الألومنيوم معدن غير قابل للاحتراق. فهو لا يشتعل أو يطلق دخاناً ساماً. وهذه ميزة قوية في سيناريوهات الحرائق. ومع ذلك، يفقد الألومنيوم قوته مع ارتفاع درجة الحرارة.

- تبلغ درجة الانصهار حوالي 660 درجة مئوية

- تنخفض القوة بشكل حاد فوق 200 درجة مئوية

- يعتمد ثبات الشكل على تصميم المظهر الجانبي

هذا يعني أن الألومنيوم آمن من وجهة نظر الاحتراق، ولكن ليس من وجهة نظر تحمل الأحمال في النار.

شرح تصنيفات مقاومة الحريق

تقاس تصنيفات مقاومة الحريق بالوقت. تشمل القيم الشائعة 30 و60 و90 و120 دقيقة. تصف هذه الأرقام المدة التي يمكن أن يستوفي فيها الهيكل معايير معينة أثناء اختبار حريق قياسي.

يتحقق الاختبار من ثلاثة أمور رئيسية:

- قدرة التحميل

- السلامة ضد مرور اللهب

- العزل ضد انتقال الحرارة

وعادةً ما تفشل قواطع الألومنيوم وحدها في معايير التحميل في وقت مبكر. ولكن عند استخدامها داخل الأنظمة، يمكن أن تتغير النتيجة.

تطبيقات وتصنيفات الألومنيوم النموذجية

| مجال التطبيق | نهج تصنيف الحرائق | التصنيف النموذجي |

|---|---|---|

| إطارات الحائط الساتر | تم اختبار النظام بالزجاج والأختام | 30 إلى 60 دقيقة |

| إطارات النوافذ | غالبًا ما تكون غير مصنفة أو ذات تصنيف محدود | من 0 إلى 30 دقيقة |

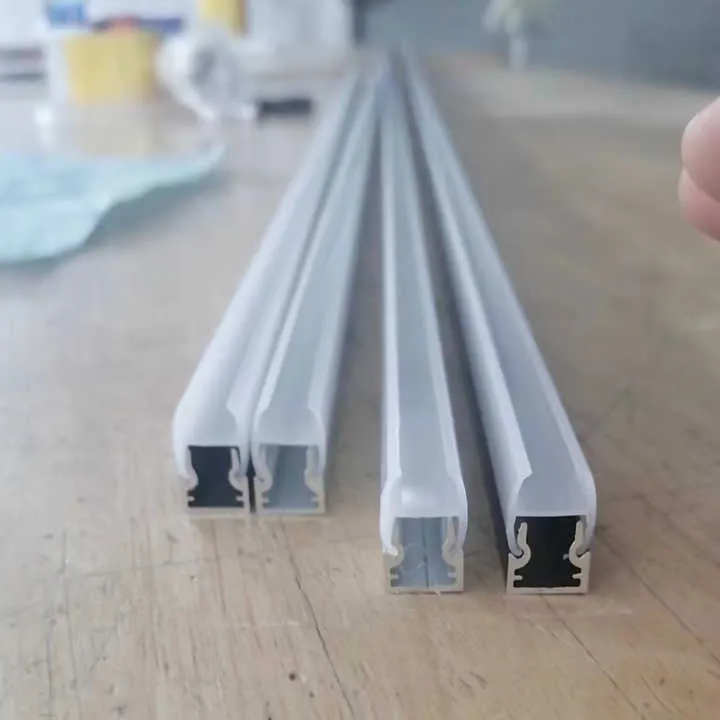

| الملامح الصناعية | يعتمد على الضميمة | النظام القائم على النظام |

| قضبان تركيب الطاقة الشمسية | عادة ما تكون غير مصنفة | غير مطلوب |

في العديد من المشاريع، يُسمح بالألومنيوم لأنه ليس عنصر التحميل الرئيسي أثناء الحريق.

استراتيجيات التصميم لتحسين أداء الحرائق

للتصميم تأثير كبير على نتائج الحريق. يمكن للجدران السميكة والأقسام المغلقة والفواصل الحرارية أن تؤخر انتقال الحرارة.

تشمل الطرق الشائعة ما يلي:

- زيادة سُمك الجدار المتزايد

- إضافة ألواح مقاومة للحريق

- استخدام الطلاءات المنتفخة

- تصميم الألومنيوم كهيكل ثانوي

هذه الطرق لا تغير الألومنيوم نفسه. فهي تغير كيفية تفاعل النظام في النار.

قواطع الألومنيوم غير قابلة للاحتراق ولا تساهم في إشعال النار.صحيح

لا يحترق الألومنيوم أو يشتعل في ظروف الحريق العادية ويصنف على أنه غير قابل للاحتراق.

تتمتع مقاطع الألومنيوم المصنوعة من الألومنيوم دائماً بمعدل مقاومة للحريق مدته 60 دقيقة افتراضياً.خطأ

تنطبق تصنيفات الحرائق على التجميعات المختبرة، وليس على تركيبات الألومنيوم المبثوقة في حد ذاتها.

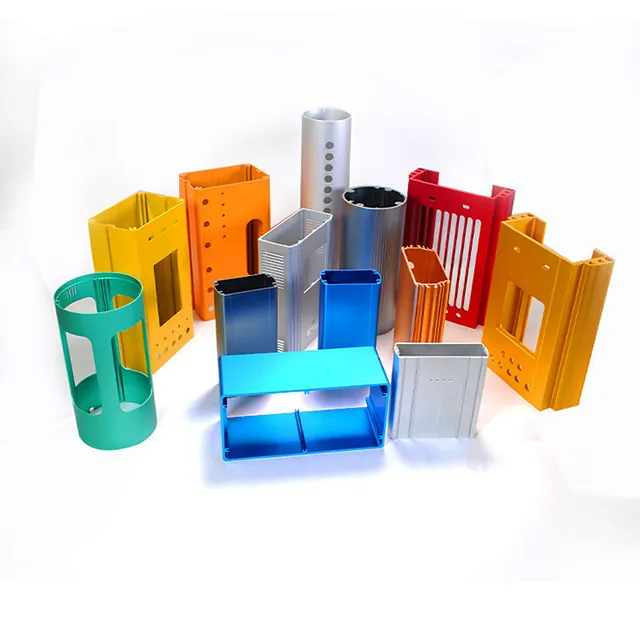

كيف تؤثر المعالجة السطحية على أداء الحرائق؟

غالبًا ما يتم اختيار المعالجة السطحية من أجل المظهر أو مقاومة التآكل. ونادراً ما تتم مناقشة سلوك الحريق، ولكنه مهم في بعض الحالات.

لا تغير المعالجة السطحية من درجة انصهار الألومنيوم، ولكنها يمكن أن تؤثر على الدخان وانتشار اللهب والتفاعل السطحي.

معالجات أسطح الألومنيوم الشائعة

تشمل العلاجات الأكثر شيوعًا ما يلي:

- الطلاء بأكسيد الألومنيوم

- طلاء المسحوق

- طلاء PVDF

- الرحلان الكهربائي

- التشطيب الميكانيكي

تضيف كل معالجة طبقة رقيقة إلى سطح الألومنيوم.

سلوك الحرائق في الطلاءات

تكون الطلاءات عضوية أو غير عضوية. هذا الفرق حاسم في الحريق.

يمكن للطلاءات العضوية، مثل طلاء المسحوق وPVDF:

- الحرق أو التحلل

- إنتاج الدخان

- تؤثر على تصنيف انتشار اللهب

لا تحترق الطلاءات غير العضوية، مثل الطلاء بأكسيد الألمنيوم، لا تحترق.

انتشار اللهب وتطور الدخان

تركز العديد من قوانين مكافحة الحرائق على مؤشرين:

- مؤشر انتشار اللهب

- مؤشر تطور الدخان

يمكن للطلاء السطحي أن يرفع كلا القيمتين.

| معالجة السطح | قابلية الاحتراق | مخاطر الدخان | تأثير الحريق |

|---|---|---|---|

| الطلاء بأكسيد الألومنيوم | غير قابلة للاحتراق | منخفضة جداً | الحد الأدنى |

| طلاء المسحوق | قابل للاحتراق | متوسط | معتدل |

| طلاء PVDF | قابل للاحتراق | متوسطة إلى عالية | أعلى |

| الرحلان الكهربائي | منخفضة | منخفضة | محدودة |

هذا هو السبب في أن بعض المشاريع العامة تقيد بعض المشاريع العامة الألومنيوم المطلي في طرق الهروب.

انتقال الحرارة وسماكة الطلاء

الطلاءات رقيقة. السماكة النموذجية هي:

- الأنودة: من 10 إلى 25 ميكرون

- طلاء البودرة: 60 إلى 120 ميكرون

لا توفر هذه الطبقات العزل. تمر الحرارة من خلالها بسرعة. لا يزيد زمن مقاومة الحريق.

اختيار المعالجة السطحية للمشاريع الحساسة للحرائق

لمشاريع مثل:

- محطات المترو

- المطارات

- المستشفيات

- سلالم السلالم الشاهقة

غالباً ما يُفضل الألومنيوم المؤكسد. فهو يفي بمتطلبات عدم الاحتراق بسهولة أكبر.

لا تضيف الأنودة مواد قابلة للاحتراق إلى أسطح الألومنيوم.صحيح

تخلق عملية الأنودة طبقة أكسيد غير عضوية وغير قابلة للاحتراق.

يعمل طلاء المسحوق على تحسين وقت مقاومة الألومنيوم للحريق.خطأ

لا يزيد طلاء المسحوق من وقت مقاومة الحريق وقد يضيف مواد قابلة للاحتراق.

هل يمكن للألمنيوم المؤكسد مقاومة درجات الحرارة العالية؟

غالباً ما يُنظر إلى الألومنيوم المؤكسد على أنه أكثر أماناً من الحرائق. وهذا صحيح جزئياً، لكنه يحتاج إلى تفسير واضح.

يقاوم الألومنيوم المؤكسد التلف السطحي في درجات الحرارة المرتفعة، ولكنه يفقد قوته مع ارتفاع درجة حرارة الألومنيوم الأساسي.

ما الذي تفعله الأنودة حقًا

تعمل عملية الأنودة على تحويل سطح الألومنيوم إلى أكسيد الألومنيوم. هذه الطبقة هي:

- صعب

- مستقر

- غير قابلة للاحتراق

يتميز أكسيد الألومنيوم بدرجة انصهار أعلى بكثير من معدن الألومنيوم.

مقارنة مقاومة درجات الحرارة

| الطبقة المادية | ثبات تقريبي |

|---|---|

| معدن الألومنيوم | يفقد قوته فوق 200 درجة مئوية |

| طبقة الأكسيد المؤكسد | مستقر فوق 1000 درجة مئوية |

| طلاء المسحوق | يتحلل حوالي 200-300 درجة مئوية |

وهذا يعني أن السطح يبقى سليماً لفترة أطول، لكن الهيكل الموجود تحته لا يزال ضعيفاً.

المظهر المرئي في التعرض للحريق

ألومنيوم مؤكسد غالباً:

- تغيير اللون

- يظهر البهتان على السطح

- يحافظ على سلامة الطلاء

ألومنيوم مطلي بالمسحوق غالباً:

- الفقاعات

- القشور

- ينتج عنه دخان

هذا الاختلاف مهم بالنسبة لفحص ما بعد الحريق وتقييم السلامة.

تبقى الحدود الهيكلية

حتى مع الطلاء بأكسيد الألمنيوم:

- تنخفض سعة الحمولة بسرعة

- زيادة الانحراف

- قد تفشل الاتصالات

الأنودة ليست حلاً مقاومًا للحريق. إنه خيار سطح أكثر أماناً.

حالات الاستخدام العملي

يشيع استخدام الألومنيوم المؤكسد في:

- درابزين النجاة من الحريق

- إطارات فرعية للواجهة

- الأماكن العامة الداخلية

- مراكز النقل

إنه يفي بقواعد الأسطح غير القابلة للاحتراق ولكنه لا يزال يعتمد على تصميم النظام لتصنيف الحرائق.

يحافظ الألومنيوم المؤكسد على ثبات السطح في درجات الحرارة العالية جداً.صحيح

طبقة الأكسيد المؤكسد مستقرة في درجات حرارة أعلى بكثير من معدن الألومنيوم.

تسمح عملية الأنودة للألومنيوم بالحفاظ على القوة الهيكلية الكاملة للألومنيوم في حالة نشوب حريق.خطأ

لا يمنع الطلاء بأكسيد الألومنيوم من فقدان قوته مع ارتفاع درجة الحرارة.

ما هي اللوائح التي تحدد متطلبات تصنيف الحرائق؟

تعتمد قواعد تصنيف الحرائق على المنطقة ونوع المبنى. يجب أن يفهم مشتري الألومنيوم المعايير المطبقة قبل عرض الأسعار أو التصميم.

تأتي متطلبات تصنيف الحرائق من قوانين البناء ومعايير الاختبار، وليس من مواصفات مواد الألومنيوم وحدها.

المعايير الدولية الرئيسية لمكافحة الحرائق

تستخدم الأسواق المختلفة أنظمة مختلفة.

- أوروبا: معايير EN

- الولايات المتحدة: ASTM و NFPA

- الشرق الأوسط قوانين الدفاع المدني

- اليابان: قانون البناء القياسي

يجب أن تتلاءم قواطع الألومنيوم مع هذه الأطر.

نظام التصنيف الأوروبي

في أوروبا، يتم تصنيف التفاعل مع الحريق من A1 إلى F.

- A1: غير قابل للاحتراق

- ج2: مساهمة محدودة

- من ب إلى و: زيادة مخاطر الحريق

الألومنيوم العاري والألومنيوم المؤكسد عادةً ما يتوافقان مع A1 أو A2. قد يقع الألومنيوم المطلي في فئات أقل ما لم يتم اختباره.

مقاومة الحريق مقابل التفاعل مع الحريق

هذه مفاهيم مختلفة.

رد الفعل على الحريق:

- كيف تساهم المواد في نشوب الحرائق

- انتشار اللهب

- دخان

مقاومة للحريق:

- مدة مقاومة التجميع للحريق

- تقاس بالدقائق

غالبًا ما يجتاز الألومنيوم التفاعل مع الحريق ولكنه يفشل في مقاومة الحريق وحده.

التوقعات التنظيمية المشتركة

| نوع المبنى | المتطلبات النموذجية |

|---|---|

| سكني | مقاومة محدودة للحريق |

| تجاري | أنظمة 30 إلى 60 دقيقة |

| شاهق الارتفاع | اختبار النظام الصارم |

| صناعي | حالة محددة |

هذا هو السبب في استخدام الألومنيوم على نطاق واسع ولكن نادراً ما يستخدم وحده في العناصر المقاومة للحريق.

مسؤولية المشتري في الامتثال

يقوم المصنعون بتوريد ملفات التعريف. يحدد المصممون الأنظمة. يقوم المقاولون بتركيب التجميعات.

يجب على المشترين:

- اطلب تقارير اختبار الحريق

- تأكيد فئة المعالجة السطحية

- مطابقة استخدام المنتج مع الكود

هذا يجنبك المخاطر في مرحلة التفتيش.

يتم تحديد متطلبات مقاومة الحريق من خلال قوانين البناء والتركيبات المختبرة.صحيح

تحدد الرموز والمعايير كيفية أداء الأنظمة في حالات الحرائق، وليس المواد الفردية وحدها.

تُلبي جميع قواطع الألومنيوم المسحوبة تلقائياً قواعد تصنيف الحرائق العالمية.خطأ

يعتمد الامتثال على التطبيق والمعالجة السطحية وتصميم النظام المختبر.

الخاتمة

تُعدّ قواطع الألومنيوم آمنة وغير قابلة للاحتراق ومقبولة على نطاق واسع في الإنشاءات. تعتمد معدلات مقاومة الحريق على تصميم النظام والمعالجة السطحية والتنظيم. يساعد فهم هذه الحدود المشترين على اختيار الألومنيوم بثقة.