ما هي حلول الإدارة الحرارية للمعدات الطبية؟

Medical devices generate heat—but failing to control it precisely can lead to malfunction, inaccurate results, or even danger to patients.

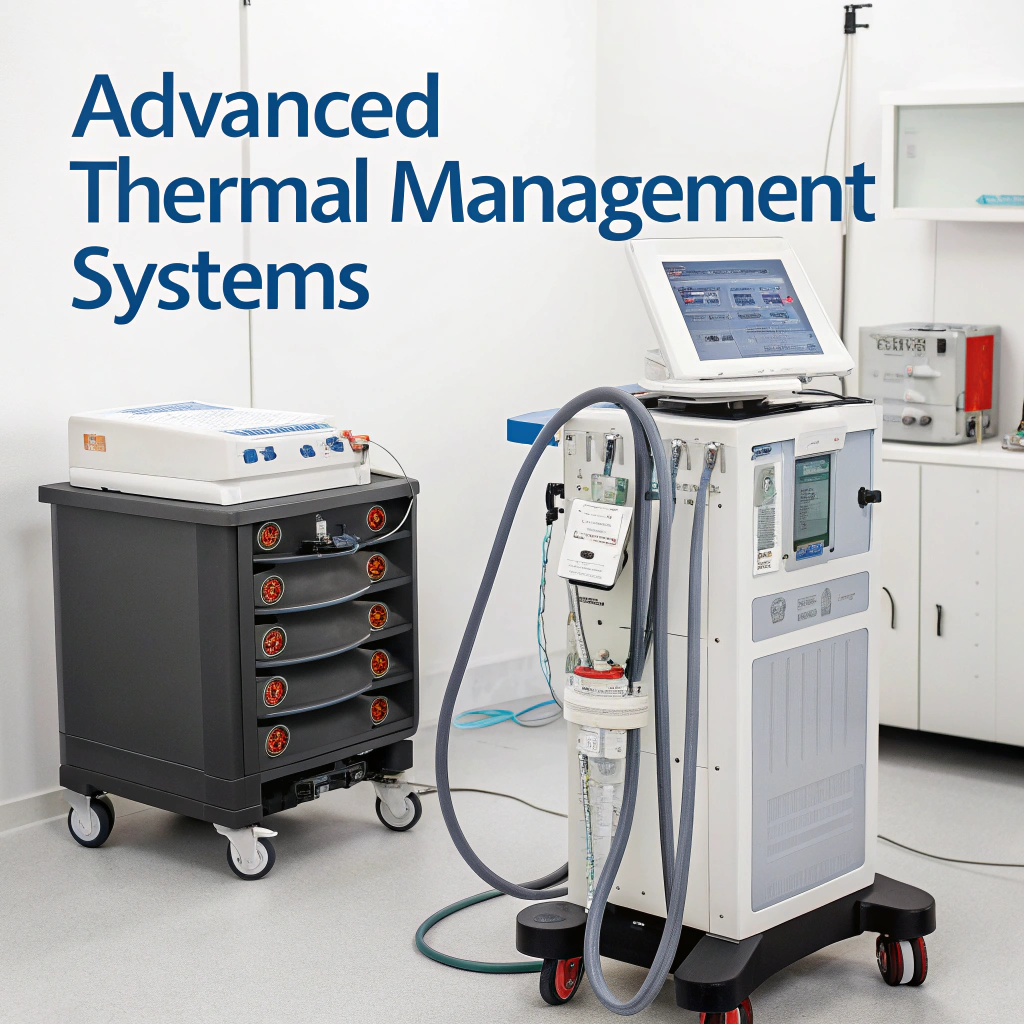

Thermal management in medical equipment uses passive and active cooling methods like heat sinks, fans, liquid cooling, and chillers to control temperature and ensure safety, precision, and reliability.

Good thermal design keeps your device safe and stable. Poor thermal control? It ruins accuracy, shortens lifespan, and increases downtime.

How Is Liquid Cooling Used in Medical Devices?

Medical electronics get smaller and more powerful. But with that power comes heat—too much for air cooling alone.

Liquid cooling in medical devices uses circulating coolant through cold plates or loops to remove excess heat, especially in high-performance or precision systems.

Liquid cooling offers several advantages over air-based systems. First, liquids have higher thermal conductivity and heat capacity than air. This means they can carry more heat away from components without a major temperature rise.

كيف تعمل

- Cold Plates: These are flat metal components attached directly to the heat source. Coolant flows through internal channels to absorb heat.

- Microchannels: In high-power components like lasers or detectors, designers use microchannels etched into metal blocks for better surface contact.

- Chillers: Often, an external chiller unit circulates the fluid, controls temperature, and manages flow rate. These chillers stay outside patient rooms to reduce noise and size.

Example Applications

| التطبيق | Liquid Cooling Role |

|---|---|

| MRI Systems | Cools magnets, gradient amplifiers |

| CT Scanners | Stabilizes electronics, cooling x-ray tube |

| Laser Therapy | Controls diode laser temperature |

| Diagnostic Instruments | Maintains thermal accuracy in analyzers |

| PCR Machines | Enables rapid and repeatable thermal cycling |

Key benefits

- Consistent Performance: No thermal spikes or hot spots.

- Compact Design: Less space needed compared to large fans or heat sinks.

- Reduced Noise: No fans or airflow means quieter operation.

- High Reliability: Steady temperatures reduce component fatigue.

Key concerns

- Leak Risks: Liquids near electronics must be contained carefully.

- Pump Reliability: Failure could lead to overheating.

- Fluid Maintenance: Coolant needs replacement and anti-corrosion treatment.

Liquid cooling systems can maintain tighter temperature control than air cooling in medical devices.صحيح

Liquid coolant has higher thermal conductivity and capacity, making it ideal for precise thermal control.

Air cooling is always more reliable than liquid cooling for medical equipment.خطأ

Liquid cooling is often more stable and efficient, especially in high-power systems.

Why Is Thermal Stability Crucial for Diagnostic Equipment?

Even small temperature swings can break the reliability of your diagnostic machine.

Thermal stability ensures diagnostic equipment maintains accuracy, repeatability, and calibration—especially in imaging, detection, and analysis systems.

Let’s look deeper into why stability matters.

Sensitive measurements

Many diagnostic tools rely on precise signal detection. X-ray detectors, MR coils, and chemical analyzers are all vulnerable to thermal drift. If the temperature changes, the baseline signal shifts. This introduces errors into the reading.

Calibration and repeatability

Medical equipment must return consistent results over time. Even a 1°C change in the device’s temperature can alter measurement outcomes.

Example Impacts

| Equipment Type | Effect of Temperature Instability |

|---|---|

| PCR Machine | Affects amplification accuracy |

| CT Scanner | Shifts calibration of imaging |

| Blood Analyzers | Alters chemical reaction rates |

| MR Systems | Warps magnetic field homogeneity |

| Optical Devices | Misaligns lenses or sensors |

Device integrity

Materials expand and contract with temperature. Optical lenses, metal housings, and sensitive detectors can misalign or shift. In CT or MRI systems, this misalignment leads to blurred or distorted images.

Regulatory compliance

Medical devices must meet standards like ISO 13485. That means they must work under defined environmental conditions. Thermal instability may push a device out of spec—and into non-compliance.

Stable temperatures improve diagnostic accuracy in medical equipment.صحيح

Temperature fluctuations cause drift in signals and affect the reliability of measurements.

Thermal stability only matters during equipment startup, not during use.خطأ

Stability during continuous operation is critical to maintain precision and reliability.

What Are Common Cooling Issues in Medical Electronics?

You’ve got a cooling system—but is it doing its job right?

Common thermal problems in medical electronics include hot spots, fan failure, dust buildup, and coolant leaks—each threatening device performance and safety.

Here’s what often goes wrong:

1. Hot Spots

Heat isn’t always evenly distributed. One processor or amplifier could run much hotter than the rest of the board. These areas can degrade faster or cause sudden shutdowns.

2. Fan Failure

If the fan motor fails or the blades wear out, airflow stops. Over time, heat builds up. Without an alert system, this may go unnoticed until the device shuts down—or worse, overheats.

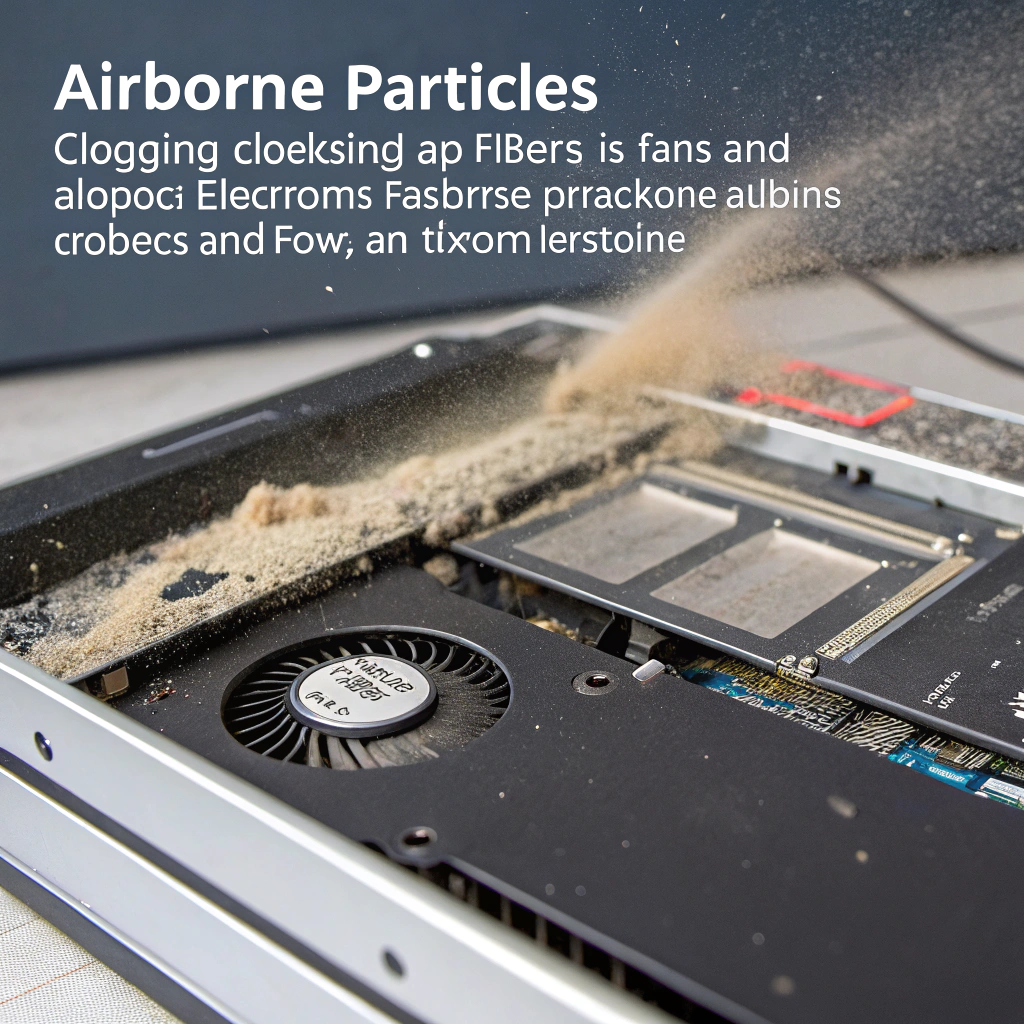

3. Dust and Debris

Airborne particles clog up fans, filters, and heat sinks. This reduces airflow and increases thermal resistance. Dust also acts as an insulator, trapping heat right where you don’t want it.

4. Coolant Leaks

In liquid systems, even tiny leaks are serious. They may corrode boards, short circuits, or cause biohazards. Medical devices must have leak-proof joints and alarms.

5. Pump Problems

A failing pump can cause uneven flow, low pressure, or cavitation. Any of these reduces cooling efficiency and may not cool critical components in time.

6. Thermal Cycling

Every time a machine heats up and cools down, materials expand and contract. Over time, this causes fatigue, solder cracking, or warping.

7. Control Instability

Poor sensor placement or slow feedback loops cause temperature swings. That leads to overcooling or undercooling—neither of which is good.

Dust buildup on heat sinks and fans can lead to reduced cooling efficiency.صحيح

Dust reduces airflow and increases insulation, causing higher component temperatures.

Coolant leaks in medical equipment are not a major concern because they rarely happen.خطأ

Even small leaks can cause serious damage and are considered high-risk failures.

How Do Medical Chillers Improve Equipment Performance?

Want better uptime, tighter control, and lower stress on your components? A chiller may be your answer.

Medical chillers provide external cooling to internal systems, improving temperature control, equipment longevity, and noise reduction in sensitive environments.

A medical chiller is a compact refrigeration system. It delivers chilled liquid to your device through a closed loop. Let’s see how it helps:

المزايا الرئيسية

- Precision Cooling: Maintains tight temperature control (±0.5°C or better).

- Noise Reduction: Moves compressors outside patient areas.

- الموثوقية: Less thermal cycling means longer component life.

- Uptime Boost: Prevents overheating and thermal shutdowns.

- Shared Cooling: One chiller can serve multiple machines.

التطبيقات

| Medical System | What the Chiller Cools |

|---|---|

| MRI | Coils, magnets, power amplifiers |

| CT | X-ray tubes, control electronics |

| Lasers | Diodes, optics, power drivers |

| Analyzers | Detectors, sample zones |

| Thermal Cyclers | Heating and cooling blocks |

Design Features

- Redundancy: Some chillers have dual compressors or backup pumps.

- Alarms: Built-in sensors trigger alerts if flow or temperature deviate.

- City Water Bypass: If chiller fails, cooling water still circulates.

- النمطية: Chillers can be added or resized with device upgrades.

- Integration: Easily connect with onboard sensors and system controllers.

Cooling Flow Example

- Chiller Unit: Located in equipment room.

- Coolant Loop: Pipes run into device.

- Cold Plate or Heat Exchanger: Transfers heat from device to fluid.

- Return Line: Warm fluid goes back to chiller for cooling.

This setup moves heat outside the room, improves thermal stability, and frees up space inside the device housing.

Medical chillers can improve diagnostic accuracy by stabilizing internal temperatures.صحيح

Consistent cooling ensures measurements remain accurate and components perform at peak.

Medical chillers are only useful in surgical tools and have no role in diagnostic imaging.خطأ

Imaging systems like MRI and CT rely heavily on chiller-based cooling.

الخاتمة

Thermal management in medical equipment isn’t just a design detail—it’s critical to safety, performance, and accuracy. From liquid loops to external chillers, every cooling decision can impact a device’s success or failure.