Anodized aluminum colors?

I know it can be tough to sort out all the color options and performance differences for anodized aluminum. You want clear help on what colors are available, how they’re made, and what works best for your project.

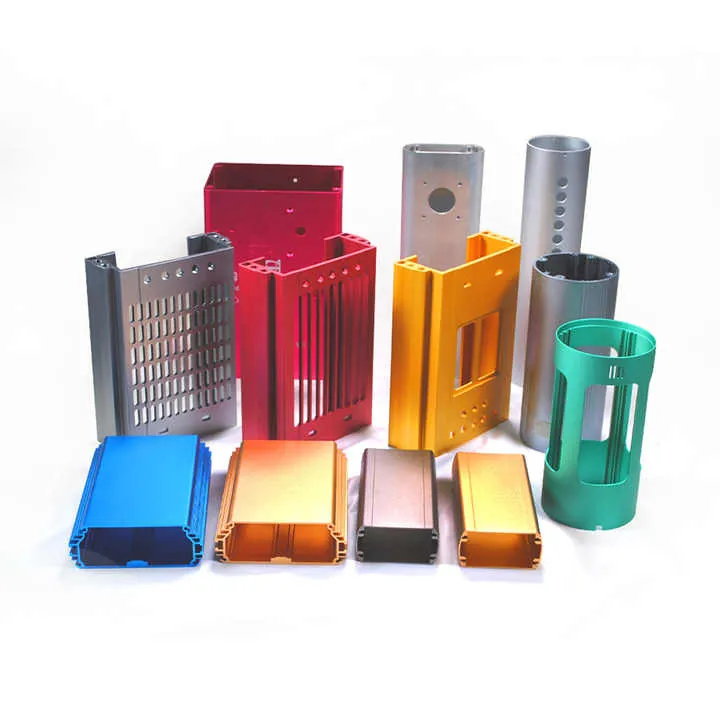

Anodized aluminum offers a wide palette—from classic silver and black to bold blues, reds, and even custom shades—all locked into the metal’s protective oxide layer for long-lasting color.

What color options are available for anodized aluminum?

Anodizing supports both standard and custom shades. Here’s a typical palette:

- Clear/silver – retains the natural aluminum look

- Black – sleek and modern

- Blue, red, green, yellow, purple, orange, pink – vibrant dye finishes

- Metallic tones (bronze, gold, chrome-like finishes) – via electrolytic or integral methods

- Metal-salt finishes (brass, pewter, satin nickel) – durable architectural options

- Custom RGB or brand-matched colors – precise dye mixes, matte or glossy

You can see the full range from standard neutrals to expressive or branded hues.

All anodized aluminum must be dyed to show color.False

Clear anodizing shows natural aluminum without dye.

Bright colors like red and blue are achieved with organic dyes.True

These colors are created by dyeing the porous oxide layer.

How do anodizing process parameters affect color?

Color results from oxide layer properties and how dyes are applied. Key factors include:

- Anodizing type

- Type II (sulfuric acid): standard colored anodizing

- Type III (hard anodize): thicker, limited color use

- Coating thickness: Thicker oxide = deeper color absorption

- Pore size and time in dye bath: Affects dye penetration and uniformity

- Dye type: Organic for vivid colors, inorganic for metallic shades

- Sealing method: Locks color in place, affects long-term durability

Color depth and accuracy rely on precise control of these parameters.

| Parameter | Effect on Color Quality |

|---|---|

| Oxide thickness | Deeper tone, better dye hold |

| Bath temperature | Warmer = faster dye absorption |

| Organic vs inorganic dye | Organic = bright, Inorganic = muted, metallic |

| Sealing method | Controls fade resistance and finish quality |

Hard anodizing supports bright red and blue colors.False

Hard anodizing results in dense oxide layers that limit bright dye use.

Thicker anodizing allows deeper and more vibrant colors.True

Thicker oxide layers absorb more dye and enhance saturation.

Are anodized aluminum colors UV-stable?

Yes—with proper process, colors remain stable outdoors:

Dark and metallic colors like black and bronze are highly UV-resistant, especially when sealed correctly.

Organic dyes for bright colors can fade if not sealed well or exposed to intense UV for years. Electrolytic colors, such as bronze or black using tin or cobalt salts, offer the best fade resistance. Using quality dyes and sealing at the correct temperature improves UV durability.

| Color Type | UV Stability | Application Suitability |

|---|---|---|

| Black (electrolytic) | Very high | Outdoor, architectural |

| Bronze (metallic) | Very high | Window frames, fa?ades |

| Red/Blue (organic) | Medium–high | Indoor, branding |

| Gold/Champagne | High | Decorative panels |

All anodized colors resist UV equally.False

Organic bright dyes are more prone to UV fading than metallic ones.

Sealing the anodized surface improves UV resistance.True

Sealing closes oxide pores and protects dye.

Which industries prefer specific anodized colors?

Different sectors choose colors based on aesthetics, branding, and durability:

| Industry | Preferred Colors | Purpose |

|---|---|---|

| Architecture | Bronze, black, silver | Weatherproof and neutral tones |

| Electronics | Black, red, blue | Branding and heat resistance |

| Aerospace & Defense | Clear, black | Meets MIL specs |

| Automotive / Sporting Goods | Metallic red, blue, gold | Visual appeal, product identity |

| Interior Design | Champagne, satin, nickel tones | Soft finishes, premium look |

Color is also used to code parts, distinguish product lines, or match corporate branding.

Aerospace companies use bright anodized colors for exterior parts.False

They prefer clear or black anodizing for durability and compliance.

Interior designers often specify champagne or satin nickel anodized finishes.True

These finishes are soft, elegant, and blend well in decor.

Conclusion

Anodized aluminum colors range from metallic neutrals to vivid dyes. With the right dye method and sealing, finishes are long-lasting and UV-stable. Industries choose specific hues based on function, durability, and design intent.

If you need help selecting a finish or matching anodizing to your application, I can guide you with samples, specifications, or performance comparisons.