What grade of aluminum is used in CNC machining?

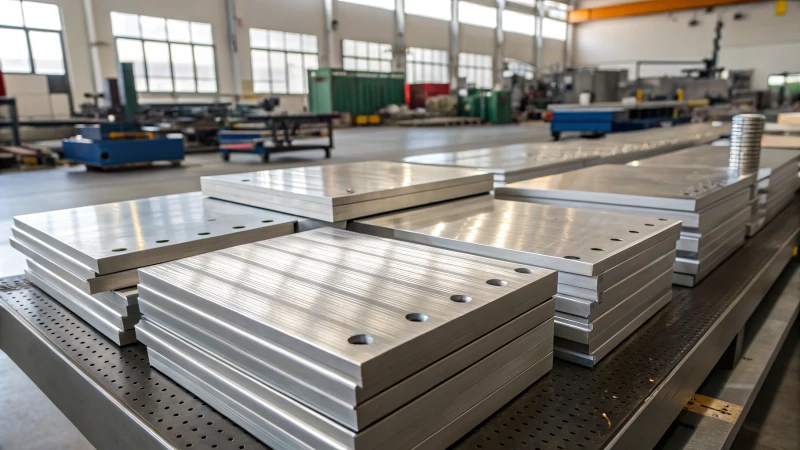

When it comes to CNC machining, selecting the right aluminum grade is vital for achieving the best results.

The most commonly used aluminum grades for CNC machining include 6061, 7075, 2024, 5052, and 3003. Each grade offers distinct properties such as machinability, strength, and corrosion resistance, making them suitable for various applications in industries like aerospace, automotive, and marine.

Understanding the unique properties of these aluminum grades will empower you to make informed decisions that enhance the quality and durability of your CNC machined products. Let’s dive deeper into each grade and discover what makes them stand out.

6061 aluminum is commonly used in CNC machining.True

6061 aluminum is favored for its good machinability and strength, making it ideal for various CNC applications.

2024 aluminum has the highest corrosion resistance among grades.False

While 2024 aluminum is strong, it does not offer the best corrosion resistance compared to other grades like 5052.

What are the key properties of 6061 aluminum?

Discover the essential properties of 6061 aluminum that make it a top choice for various engineering and manufacturing applications.

6061 aluminum is known for its excellent machinability, medium strength, very good corrosion resistance, and good weldability, making it ideal for diverse applications in aerospace, automotive, and construction.

Overview of 6061 Aluminum Properties

6061 aluminum is one of the most commonly used alloys in the aluminum family due to its versatile properties. It offers a remarkable balance of strength, workability, and corrosion resistance, making it suitable for various applications.

Key Properties

| Property | Value |

|---|---|

| Machinability | Excellent |

| Strength | Medium |

| Corrosion Resistance | Very good |

| Weldability | Good |

| Density | 2.70 g/cm³ |

| Thermal Conductivity | 150 W/(m·K) |

These properties make 6061 aluminum a popular choice in industries ranging from aerospace to automotive and construction.

Strength and Durability

6061 aluminum provides medium strength, which is sufficient for many structural applications. It exhibits a tensile strength of about 240 MPa (35,000 psi), making it robust for various engineering designs. Its durability ensures that components made from this alloy can withstand harsh conditions without deforming.

Corrosion Resistance

One of the standout features of 6061 aluminum is its excellent resistance to corrosion. This property allows it to maintain its integrity when exposed to moisture and various atmospheric conditions, which is essential in applications like marine environments1 or outdoor structures.

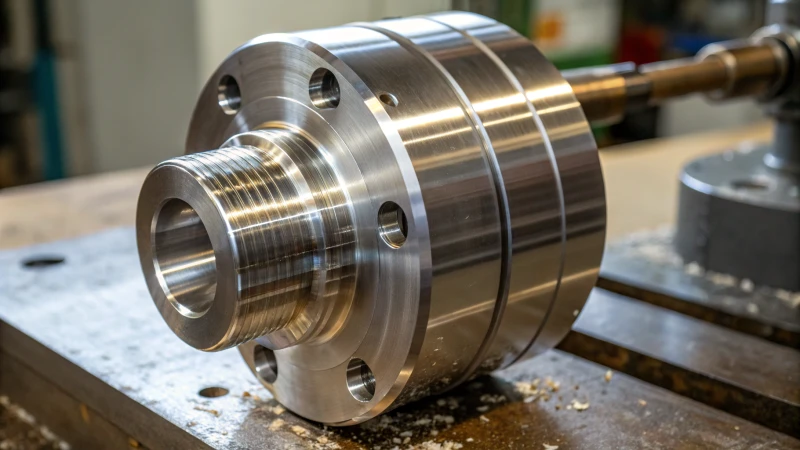

Workability and Machinability

6061 aluminum is renowned for its ease of machining. It can be easily cut, shaped, and formed into various designs, which is crucial for CNC machining2. This quality not only speeds up production but also allows for intricate designs that are difficult to achieve with other metals.

Applications of 6061 Aluminum

Due to its properties, 6061 aluminum is widely used in:

- Aerospace: Aircraft components where weight and strength are critical.

- Automotive: Parts such as frames and supports that require durability without adding excessive weight.

- Marine: Boat structures and parts exposed to salty environments.

- Construction: Structural elements such as beams and trusses.

For further exploration of its applications, you might find the following topics helpful: 6061 aluminum in aerospace3 or best practices for machining aluminum4.

Conclusion

While this section focuses on the key properties of 6061 aluminum, it’s crucial to understand how these properties influence its selection in real-world applications. Whether considering strength, corrosion resistance, or machinability, 6061 aluminum continues to be a premier choice across multiple industries.

6061 aluminum has excellent machinability properties.True

This claim is true; 6061 aluminum is renowned for its ease of machining, allowing for intricate designs and efficient production.

6061 aluminum is unsuitable for marine applications.False

This claim is false; 6061 aluminum's corrosion resistance makes it ideal for marine environments and outdoor structures.

How does 7075 aluminum compare to other grades?

Exploring the unique qualities of 7075 aluminum reveals how it stands out among other grades. Let’s dive into its comparison with widely used alloys like 6061 and 5052.

7075 aluminum offers high strength and moderate machinability compared to other grades like 6061 and 5052. While it excels in structural applications, its corrosion resistance is not as robust as 6061, making material selection critical for specific uses.

Understanding the Strength of 7075 Aluminum

7075 aluminum is renowned for its high strength, making it one of the strongest alloys available. This characteristic makes it particularly appealing for applications where strength is crucial, such as in the aerospace and military industries.

In comparison:

- 6061 Aluminum offers medium strength, making it versatile but less robust than 7075.

- 2024 Aluminum surpasses both in strength but has lower corrosion resistance.

This difference in strength is often the deciding factor for engineers when selecting materials for critical components.

Machinability Challenges

While 7075 aluminum excels in strength, it poses challenges during the machining process. It has moderate machinability, which means that it requires more advanced setups and tooling compared to 6061 aluminum. For instance:

- 6061: Excellent machinability, allowing for easier processing and faster production times.

- 7075: Requires specialized tools, potentially leading to increased production costs.

Machinists often need to adjust their strategies when working with 7075, impacting overall project timelines and budgets. Learn more about machining strategies5.

Corrosion Resistance Comparison

When considering corrosion resistance, 7075 aluminum is decent but not as robust as 6061.

| Alloy | Corrosion Resistance | Best Applications |

|---|---|---|

| 6061 | Very Good | Structural, automotive |

| 7075 | Good | Aerospace, military |

| 5052 | Excellent | Marine environments |

This table highlights the necessity of choosing the right aluminum grade based on the environment the material will be exposed to. For outdoor applications, 5052 might be preferable due to its superior resistance to corrosion.

Cost Considerations

Cost plays a significant role in selecting aluminum grades. 7075 aluminum tends to be more expensive due to its complex production process and high-performance characteristics. In contrast:

- 6061 is usually more budget-friendly, making it a popular choice for a wide range of applications.

- 5052 might also be competitive depending on the specific requirements for corrosion resistance.

Understanding the cost-benefit analysis is essential for decision-makers like David, who prioritize quality but also keep an eye on the budget. Explore more about cost analysis6.

Summary of Applications

7075 aluminum’s unique properties lead to its use in high-performance applications:

- Aerospace parts: Where weight-to-strength ratio is critical.

- Military components: That require both durability and reliability under stress.

Comparatively, 6061 is widely used for everyday applications, while 5052 is a go-to for marine environments due to its corrosion resistance. Understanding these applications helps businesses align their material choices with their operational needs. Find out more about material applications7.

7075 aluminum is stronger than 6061 aluminum.True

7075 aluminum is known for its high strength, surpassing the medium strength of 6061, making it ideal for demanding applications.

7075 aluminum has better corrosion resistance than 5052.False

7075 aluminum offers good corrosion resistance, but 5052 provides excellent resistance, making it preferable for marine environments.

What applications benefit most from 2024 aluminum?

2024 aluminum is renowned for its high strength and fatigue resistance. But which applications benefit most from this versatile alloy? Let’s explore its key uses across various industries.

Applications that benefit most from 2024 aluminum include aerospace components, military vehicles, high-performance automotive parts, and industrial tooling where high strength and low weight are critical.

Aerospace Applications

One of the primary fields that benefit from 2024 aluminum is aerospace.

This alloy’s high strength-to-weight ratio makes it an ideal choice for structural components in aircraft. For example, parts like fuselage frames and wing structures can leverage 2024’s properties to reduce overall weight while maintaining strength.

Furthermore, 2024 aluminum exhibits excellent fatigue resistance, essential in the aerospace sector where materials are subjected to repetitive stress during flight operations.

- Advantages: High strength, low weight, excellent fatigue performance.

- Common Uses: Aircraft frames, wing skins, and cargo floor structures.

Military Applications

In military contexts, 2024 aluminum is preferred for its robust characteristics.

Military vehicles, missile components, and other defense-related applications utilize this alloy due to its ability to withstand high-stress environments. 2024 aluminum is often seen in combat vehicles and military aircraft where reliability is critical.

| Application Type | Advantages | Example Components |

|---|---|---|

| Military Vehicles | High durability | Armored transport vehicles |

| Aerospace | Lightweight | Fighter jets and helicopters |

| Defense Equipment | Fatigue resistance | Missile bodies and launchers |

Automotive Sector

The automotive industry has also recognized the benefits of using 2024 aluminum, particularly in high-performance vehicles.

Components that require both lightweight and high strength are often made from this alloy, which helps improve fuel efficiency without compromising safety. Parts such as suspension systems and chassis components frequently employ 2024 aluminum to achieve this balance.

- Performance: Enhanced speed and efficiency through reduced weight.

- Common Uses: Suspension arms, high-stress chassis components.

High-Stress Industrial Components

Industries involving high-stress machinery or components also find 2024 aluminum advantageous.

This includes manufacturing settings where parts are exposed to significant loads or fatigue cycles. For instance, tooling and fixtures can be made from 2024 aluminum to ensure longevity and reliability in production lines.

| Industry | Component Type | Benefit |

|---|---|---|

| Manufacturing | Tooling & Fixtures | Extended service life |

| Heavy Equipment | Structural Components | Reduced weight for better mobility |

| Oil & Gas | High-load Components | Increased safety under stress |

For those looking to maximize performance in demanding applications, understanding the specific benefits of 2024 aluminum compared to alternatives like 60618 and 7075 is crucial.

2024 aluminum is ideal for aerospace structural components.True

The high strength-to-weight ratio of 2024 aluminum makes it perfect for aircraft parts, enhancing performance while reducing weight.

2024 aluminum is unsuitable for military applications.False

Contrary to this claim, 2024 aluminum is widely used in military vehicles due to its durability and reliability under stress.

Why is corrosion resistance important in CNC machining?

Corrosion resistance is a key factor in CNC machining that significantly influences product durability and performance. Why is it so important? Let’s delve into its implications.

Corrosion resistance in CNC machining is vital for ensuring the durability and reliability of components exposed to harsh environments. It directly impacts product lifespan and maintenance costs, making it crucial for material selection.

Understanding Corrosion Resistance in CNC Machining

Corrosion resistance is a critical aspect of CNC machining, particularly when selecting materials for components used in various environments. It ensures that the machined parts can withstand exposure to moisture, chemicals, and other corrosive elements without degrading.

This resistance not only prolongs the lifespan of the components but also helps maintain their integrity and performance over time. For instance, aluminum grades like 6061 and 5052 are chosen frequently due to their excellent corrosion resistance properties, making them suitable for applications in marine environments and other harsh conditions.

Impact on Product Lifespan

The durability of CNC machined products directly correlates with their resistance to corrosion. Parts that corrode quickly will require more frequent replacements, increasing costs and downtime. For example, when using 2024 aluminum, which has moderate corrosion resistance, additional coatings may be needed if the components are exposed to wet environments.

| Aluminum Grade | Corrosion Resistance | Typical Applications |

|---|---|---|

| 6061 | Very Good | Structural components, automotive |

| 7075 | Good | Military, aerospace |

| 2024 | Moderate | Aircraft structures |

| 5052 | Excellent | Marine equipment |

| 3003 | Good | Cooking utensils |

Cost Implications

Choosing materials with high corrosion resistance might lead to higher upfront costs, but it can result in significant savings over time by reducing maintenance and replacement needs. This is especially relevant for industries where reliability is paramount, such as aerospace and automotive sectors. Investing in corrosion-resistant materials can enhance the overall value of the final product.

Enhancing Performance Through Coatings

In some cases, even materials with lower natural corrosion resistance can be made suitable for specific applications through protective coatings. Techniques such as anodizing or applying epoxy paints can greatly improve the longevity of parts made from materials like 2024 aluminum. These treatments can provide an extra layer of defense against corrosive environments while maintaining aesthetic qualities.

For further insights on coating techniques9, check out this resource that dives deeper into different methods and their effectiveness.

Conclusion

In CNC machining, prioritizing corrosion resistance leads to better product reliability and longevity. By understanding the importance of this attribute and making informed material choices, manufacturers can ensure that their machined components perform optimally under various conditions. For more detailed information about material selection in CNC machining, consider exploring our guide on aluminum grades.

Corrosion resistance directly affects CNC machined product lifespan.True

Components with high corrosion resistance last longer, reducing replacement frequency and costs.

Higher upfront costs for corrosion-resistant materials are unjustified.False

Investing in corrosion-resistant materials saves money over time by minimizing maintenance and replacements.

How to choose the right aluminum grade for your project?

Choosing the right aluminum grade is crucial for ensuring your project meets its performance and durability goals. Here’s how to navigate this important decision.

To choose the right aluminum grade for your project, consider factors like strength requirements, corrosion resistance, and machinability. Common grades include 6061 for general use, 7075 for high strength, and 5052 for marine applications.

Understanding Aluminum Grades

Choosing the right aluminum grade involves understanding its properties and how they align with your project’s requirements. Below is a comparison of commonly used aluminum grades:

| Aluminum Grade | Strength | Corrosion Resistance | Machinability | Typical Applications |

|---|---|---|---|---|

| 6061 | Medium | Very Good | Excellent | Structural components, automotive, aerospace |

| 7075 | High | Good | Moderate | Military, aerospace, high-performance automotive |

| 2024 | Very High | Moderate to Poor | Good | Aircraft structures, military applications |

| 5052 | Moderate | Excellent | Good | Marine environments, tanks, chemical processing |

| 3003 | Low | Good | Excellent | Cooking utensils, heat exchangers, siding |

Key Factors to Consider

When selecting an aluminum grade for your project, consider these key factors:

- Strength Requirements: Determine the load and stress your project will encounter. For high strength needs, 7075 or 2024 are preferred options. For general purposes, 6061 is ideal.

- Corrosion Resistance: Assess the environment where your aluminum will be used. If it’s in a marine setting, 5052 offers the best protection against corrosion. In contrast, 2024 may not be suitable for wet conditions without coatings.

- Machinability: If you need to machine the aluminum, some grades are easier to work with than others. 6061 and 3003 are excellent for machining, while 7075 can be more challenging.

Practical Application Examples

To help visualize how these grades perform in real-world scenarios:

- For outdoor car travel tents, consider 6061 for its balance of strength and corrosion resistance.

- In military applications where strength is critical, 7075 is often the go-to due to its high strength.

- If your design is for cooking utensils, 3003 is lightweight and easy to machine.

Additional Considerations

- Cost vs. Quality: Higher strength alloys often come with increased costs and complexity in machining. Assess whether the added strength justifies the cost for your project.

- Supplier Capabilities: Ensure that your supplier can meet the specific requirements for machining and finishing your chosen aluminum grade. This will prevent delays and ensure quality.

For further insights into aluminum properties and selecting the best options for your needs, check out this detailed guide10.

6061 aluminum is ideal for marine applications.False

While 6061 has good corrosion resistance, 5052 is better suited for marine environments due to its excellent corrosion resistance.

7075 aluminum offers the highest strength among common grades.True

7075 aluminum is known for its high strength, making it suitable for military and aerospace applications requiring robust materials.

Conclusion

This post discusses key aluminum grades used in CNC machining, highlighting their properties and applications to help make informed material choices.

-

Explore this link to gain insights into the unique advantages of 6061 aluminum in various industries. ↩

-

This link offers valuable information on machining techniques specific to aluminum alloys, enhancing your understanding of practical applications. ↩

-

Learn more about the role of corrosion resistance in material selection by visiting this informative page. ↩

-

Find best practices for working with aluminum materials, ensuring quality outcomes in manufacturing processes. ↩

-

Clicking this link will provide you with detailed machining strategies tailored for 7075 aluminum, enhancing your project efficiency. ↩

-

This link will guide you through a comprehensive cost analysis of different aluminum grades, helping you make informed decisions for your projects. ↩

-

Exploring this resource will help you understand the diverse applications of various aluminum alloys, ensuring the right choice for your needs. ↩

-

Discover how 2024 aluminum can enhance your project outcomes in aerospace and military applications by exploring this insightful resource. ↩

-

Understanding the importance of corrosion resistance will help you select better materials for your projects, enhancing durability and performance. ↩

-

Explore this link for expert advice on aluminum grades to ensure your project’s success. ↩