Aluminum Bullnose Trim Designed for Decoration?

If you’ve ever noticed how some rooms feel perfectly finished, it’s likely because they used trim smartly—especially bullnose trim.

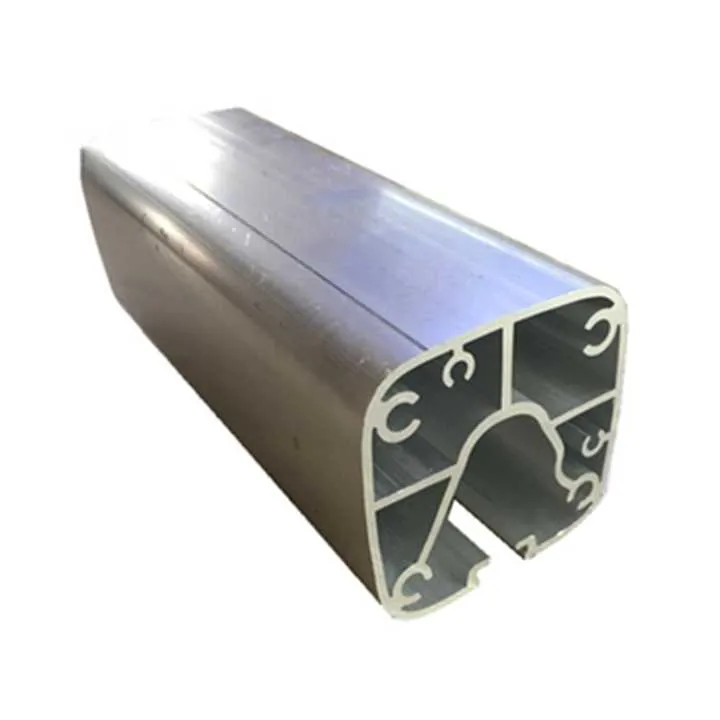

Bullnose trim is a rounded-edge profile used to soften corners, finish transitions, and add a sleek, decorative edge—especially when made from durable aluminum.

If you’re looking for a practical yet elegant way to finish edges or frame LED lighting, bullnose aluminum trim gives you the strength and beauty in one simple upgrade.

What is bullnose trim and why use it for decoration?

We’ve all seen sharp, raw edges ruin the look of a space. Exposed tile corners or LED frames can look incomplete.

Bullnose trim is an L-shaped or rounded profile that softens sharp corners, protects edges, and delivers a clean, finished look, especially in decorative applications like walls, ceilings, and LED framing.

Bullnose trim is named for its curved, “nose-like” profile. Unlike sharp 90-degree edges, bullnose has a rounded front that visually smooths transitions between materials or surfaces. Originally used in tile work and drywall finishing, aluminum bullnose trim is now widely used in modern interior and architectural design.

Here’s what makes it popular:

Key Benefits of Bullnose Trim

| Feature | Why It Matters |

|---|---|

| Rounded Finish | Makes edges safer and more attractive |

| Material Protection | Prevents chipping or cracking at corners |

| Visual Softness | Reduces harsh lines and shadows |

| Versatile Use | Works on walls, ceilings, furniture, LED edges |

| Material Options | Aluminum, PVC, wood—aluminum stands out for strength and style |

Aluminum versions are especially favored for modern design projects. They are lightweight, corrosion-resistant, and available in anodized, brushed, or powder-coated finishes. For commercial or luxury interiors, this makes a big difference.

Designers also use bullnose trim to elevate visual hierarchy. For example, adding an aluminum bullnose border around LED panels not only hides harsh edges but adds a reflective, upscale look.

Bullnose trim is designed to create a soft, rounded edge at surface transitions.True

Bullnose trims feature a curved design that softens the look and feel of edges, making them safer and more elegant.

Bullnose trim is primarily used for mechanical insulation.False

While some trims serve technical purposes, bullnose trim is primarily decorative and protective in interior design and finishing.

How to install bullnose aluminium trim around LED strips?

Nothing ruins a good lighting job like jagged corners and messy finishes.

To install bullnose aluminum trim around LED strips, measure and cut accurately, secure with adhesive or clips, and align with the light strip for a seamless, polished edge.

Installation doesn’t have to be complicated. Here’s how I typically install bullnose aluminum trim around LED lighting:

Step-by-Step Installation Guide

1. Plan the Layout

Start by sketching or visualizing how the trim will frame the LED strip. Mark start and end points clearly.

2. Measure and Cut

Use a measuring tape for accurate length. A miter saw or fine-toothed hacksaw is ideal for aluminum. For corners, miter cuts at 45° give the cleanest finish.

3. Prepare the Surface

Clean the mounting surface of dust or debris. If mounting on drywall or tile, ensure the surface is smooth.

4. Mount the Trim

Depending on the application:

- Adhesive: Use construction-grade glue or double-sided tape for small projects.

- Clips or Screws: Use metal clips or pre-drilled holes for a stronger hold—especially on ceilings or long horizontal runs.

5. Install LED Strip Inside

Place the LED strip inside the trim channel. Use adhesive backing or mounting brackets to secure it.

6. Add Diffuser or Cover (if applicable)

Some bullnose trims come with a slot for a diffuser lens. This adds a frosted finish that softens LED glare.

7. Seal and Finish

Attach end caps if needed. Fill minor gaps with silicone for a seamless transition.

| Tool | Purpose |

|---|---|

| Miter Saw | For clean angled cuts |

| Adhesive or Clips | To fix the trim in place |

| Measuring Tape | Ensures accuracy |

| File or Sandpaper | Smooths rough edges |

| Level | Keeps installation straight |

Proper installation not only makes the lighting cleaner but enhances the architectural lines in a room.

Bullnose aluminum trim can be installed using both adhesives and screws, depending on the surface.True

For flexible or permanent mounting, users can choose either method based on the environment and project.

Bullnose trim cannot be used around lighting installations.False

In fact, bullnose trim is often used around LED strips to frame the lighting and improve appearance.

Which finishes make bullnose trim decorative and durable?

Many trims look good at first, but fade or scratch easily over time. Not with the right finish.

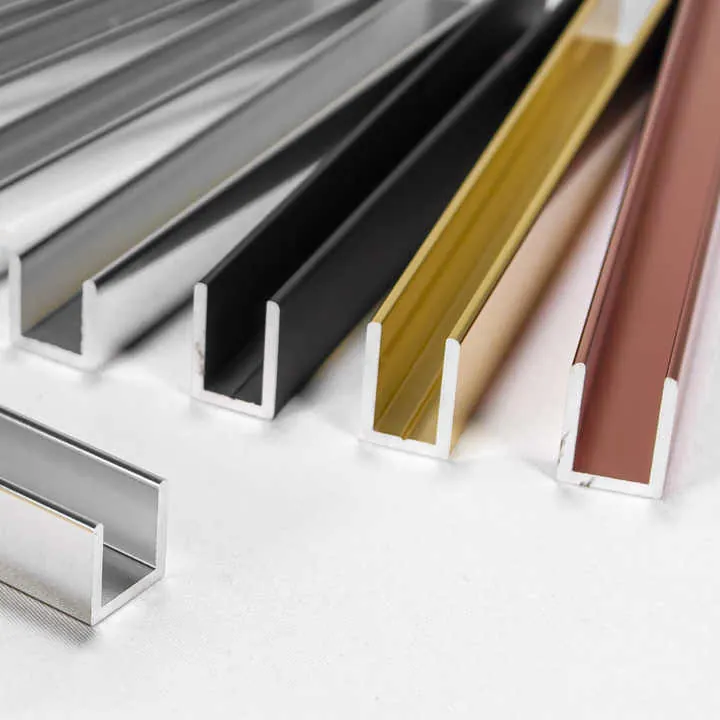

Finishes like anodizing, powder coating, or brushed metal textures make bullnose trim not only visually appealing but highly resistant to corrosion, UV, and wear.

Aluminum itself is strong, but the finish makes all the difference. A raw aluminum edge can oxidize, dull, or scratch easily. That’s why most bullnose trims are finished in one of these ways:

Common Finishing Options

| Finish Type | Description | Benefit |

|---|---|---|

| Anodized Aluminum | Electrochemical treatment | Scratch-resistant, matte or glossy |

| Powder Coated | Dry-powder heat-baked coat | Tough, colorful, weatherproof |

| Brushed Finish | Mechanically textured | Hides fingerprints, premium feel |

| Polished Aluminum | Mirror-like smooth finish | Reflective, decorative, modern |

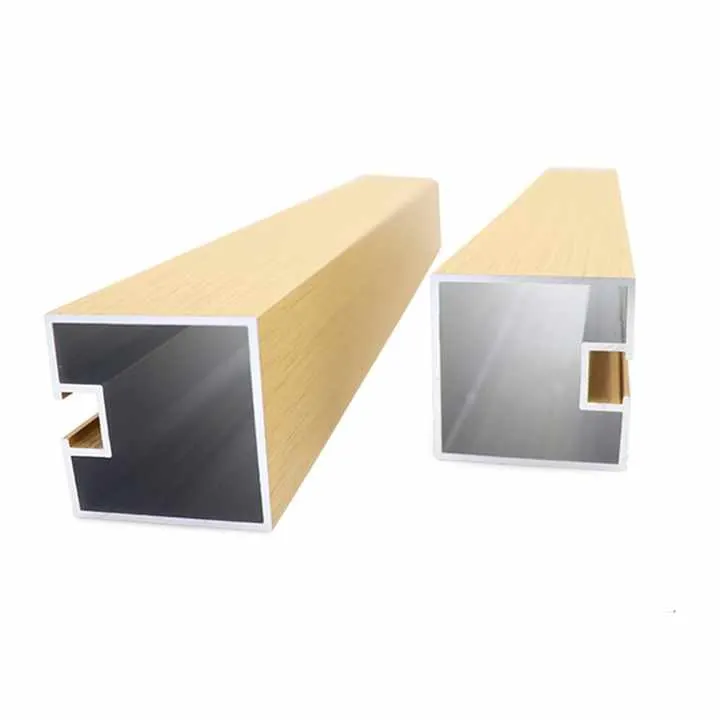

| Wood Grain Print | Printed faux finish | Warmth without real wood issues |

Each has its place. For outdoor use, I often go for powder-coated black or white—clean, strong, UV-safe. Indoors, brushed aluminum offers a luxury feel that matches most LED frames or recessed panels.

Designers often match trim finish with other materials:

- Stainless-look brushed trim with appliances

- Matte black anodized with dark tile or minimal LED strips

- White powder-coated for baseboards and ceilings

This not only protects the edge but makes the space look thoughtful and consistent.

Anodizing enhances both the durability and appearance of aluminum trim.True

Anodizing protects aluminum from wear while offering matte or glossy finishes that suit modern design.

Painted aluminum trim offers better corrosion resistance than anodized.False

Powder coating is durable, but anodizing provides superior corrosion resistance and integrates with the metal.

Can bullnose trim be customized for unique decorative styles?

Design isn’t one-size-fits-all. That’s why customization matters.

Yes, aluminum bullnose trim can be customized in shape, finish, size, or mounting method to match unique styles, branding, or architectural requirements.

Custom options give designers the power to personalize. At Sinoextrud, for example, we’ve helped clients design custom curved trims for boutique hotels and ultra-thin profiles for display frames.

What Can Be Customized?

| Feature | Customization Examples |

|---|---|

| Size | From 6mm to 50mm radius, varied length |

| Color | RAL powder coat, anodized tints, wood grain |

| Curves & Corners | Arched bullnose, multi-face trim |

| Mounting Style | Hidden clips, screw flanges, snap-in |

| LED Integration | Built-in diffuser slots, rear cable channels |

These options help brands express their identity, or help architects match a specific design vision—whether minimalist, retro, or industrial.

Let’s say I need a curved aluminum bullnose to fit a custom-built staircase lined with LED lights. Standard trims won’t bend smoothly. So I might order a bendable aluminum alloy or have a segmental design made.

Or I’m outfitting a luxury spa. I might request brushed champagne anodizing to blend with brass accents.

With enough planning, I can match bullnose trim to lighting tone, tile texture, or architectural rhythm. This isn’t just detail work—it’s the design language that elevates a space.

Bullnose trim can be customized in shape, color, and mounting style to fit project needs.True

Custom options allow designers to tailor trim to fit both functional and aesthetic requirements.

Only standard, pre-finished bullnose trims are suitable for decorative use.False

Manufacturers like Sinoextrud offer a wide range of customizable options to meet high-end decorative demands.

Conclusion

Aluminum bullnose trim is more than a finishing edge—it’s a design statement. Whether framing LED strips, softening wall corners, or creating luxury transitions, it adds both function and beauty. With the right materials, finish, and installation, it turns a plain project into a polished, modern result.