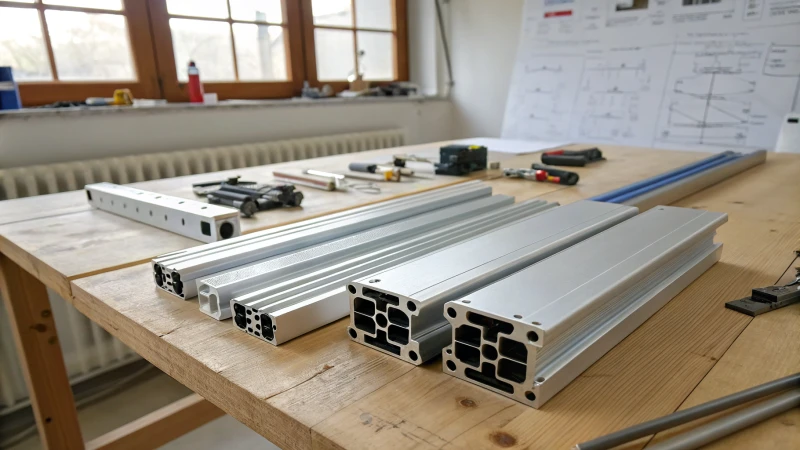

What is Aluminium T Slot Profile?

Discover the world of aluminium T-slot profiles, a revolutionary solution for building modular structures!

Aluminium T-slot profiles are extruded aluminium components featuring a T-shaped groove that allows easy assembly of customizable frames for various applications. Their lightweight yet durable design makes them a favorite in many industries.

In this blog post, we delve deeper into the key features, applications, and benefits of aluminium T-slot profiles. Whether you’re an engineer, designer, or DIY enthusiast, this comprehensive guide will equip you with valuable insights.

What are the Key Benefits of Aluminium T-Slot Profiles?

Aluminium T-slot profiles offer numerous advantages that make them ideal for various engineering and manufacturing applications. Let’s explore these benefits in detail!

Aluminium T-slot profiles provide customizability, modularity, strength, ease of assembly, and cost-effectiveness, making them perfect for diverse engineering projects.

1. Customizability

One of the most significant advantages of aluminium T-slot profiles is their customizability.

You can easily modify the size, height, or shape of a structure to meet specific needs without starting from scratch.

This flexibility is particularly beneficial for projects that evolve over time, allowing for quick adjustments to designs.

For instance, if you are designing a workstation that needs to accommodate new equipment, T-slot profiles can be reconfigured without major disruptions.

2. Modular Design

The modular nature of T-slot systems allows for creating various structures without complex engineering.

You can combine different sizes and types of profiles to create everything from simple shelving units to complex automation systems.

This modularity helps save both time and resources, as components can be reused in different projects.

| Feature | Description |

|---|---|

| Modularity | Easily reconfigure and adapt for different needs |

| Reusability | Components can be reused across multiple projects |

| Scalability | Scale your structures up or down as required |

3. Strength and Durability

Despite being lightweight, aluminium T-slot profiles are engineered for strength and durability.

The unique T-slot design distributes load effectively, ensuring that even heavy structures maintain integrity under weight.

This makes them ideal for applications where reliability is crucial, such as in machinery frames.

4. Ease of Assembly

Aluminium T-slot profiles simplify assembly processes.

They can be quickly assembled using standard fasteners like T-nuts and bolts, eliminating the need for welding or specialized tools.

This ease of assembly translates to reduced labor costs and faster project completion times.

Moreover, the ability to adjust connections easily allows for quick modifications when necessary.

5. Cost-Effectiveness

While the initial investment might seem higher than traditional framing materials, the long-term benefits of aluminium T-slot profiles make them a cost-effective solution.

Their durability leads to lower maintenance costs and a longer lifespan compared to other materials like steel.

Additionally, the reduced labor costs associated with their installation enhance overall project value.

For those considering options for industrial applications, T-slot profiles offer an appealing financial advantage.

Summary of Key Benefits

Here’s a quick reference table summarizing the key benefits of aluminium T-slot profiles:

| Benefit | Description |

|---|---|

| Customizability | Easily adaptable to changing project requirements |

| Modularity | Allows for diverse structure creation |

| Strength and Durability | Capable of supporting significant loads without failure |

| Ease of Assembly | Quick assembly with standard tools |

| Cost-Effectiveness | Long-term savings through durability and low maintenance |

How Do You Assemble Structures Using T-Slot Profiles?

Assembling structures using T-slot profiles is a straightforward yet versatile process that allows for creativity and customization in design. Let’s explore how to effectively build these systems.

To assemble structures using T-slot profiles, start by planning your design, gathering necessary tools like T-nuts and bolts, cutting profiles to size, and following a step-by-step assembly process for optimal results.

Understanding the Basics of T-Slot Profiles

Assembling structures with T-slot profiles begins with understanding the components. A T-slot profile consists of an extruded aluminium bar with a unique T-shaped groove. This groove is essential for attaching various hardware, such as brackets, nuts, and bolts, which facilitate easy assembly and disassembly. To gain a better grasp, you can check out T-slot assembly essentials.

Tools Required for Assembly

Before you start assembling, ensure you have the following tools:

| Tool | Purpose |

|---|---|

| T-nuts | Used to fasten components within the T-slot |

| Bolts | Securely connect different parts |

| Allen Wrench | Tighten bolts without damaging the profile |

| Measuring Tape | For accurate measurements |

| Level | Ensure structures are even and aligned |

Having the right tools makes the assembly process smoother and more efficient. Learn more about essential tools for T-slot assembly.

Step-by-Step Assembly Process

- Plan Your Structure: Before starting, draft a layout of your desired structure, identifying the components and their measurements.

- Cutting the Profiles: Use a saw to cut the T-slot profiles to your required lengths. Ensure that the cuts are straight and clean for proper assembly.

- Attaching the Base: Begin with the base of your structure. Lay down the profile pieces in a rectangular shape and secure them using T-nuts and bolts. Ensure that they fit snugly in the grooves.

- Building Upwards: Once the base is secure, start attaching vertical profiles. Insert T-nuts into the horizontal profiles’ grooves and secure them with bolts. Repeat this process until your desired height is achieved.

- Reinforcing Corners: For added strength, consider using corner brackets at joints to enhance stability. Place brackets at each corner and secure them with bolts for extra support.

- Final Adjustments: As you build, periodically check with a level to ensure everything is aligned correctly. Make adjustments as necessary to maintain a sturdy structure.

For detailed assembly visuals, check out visual guides for T-slot assembly.

Customization Options

The modular nature of T-slot profiles allows for endless customization possibilities. You can:

- Add shelves or work surfaces at any height.

- Integrate additional components like wheels or casters for mobility.

- Customize the structure’s design to fit specific applications, such as creating enclosures or workstations.

Explore more about customizing your T-slot structures.

What Types of Projects Can Benefit from Aluminium T-Slot Profiles?

Discover the diverse projects that can benefit from the unique capabilities of aluminium T-slot profiles.

Aluminium T-slot profiles are perfect for customizable workstations, industrial machinery frames, racking systems, protective enclosures, automation setups, and DIY projects due to their modularity and ease of assembly.

Versatile Applications of Aluminium T-Slot Profiles

Aluminium T-slot profiles are incredibly versatile, making them suitable for a range of projects. Here’s a detailed breakdown of their applications:

1. Custom Workstations

Many industries utilize T-slot profiles to create customized workstations. The modular nature allows for adjustments in height and configuration, catering to specific tasks. For example, a customizable workstation can be designed to fit various tools and equipment based on the needs of the user.

2. Industrial Machinery Frames

T-slot profiles are extensively used to build frames for industrial machinery. Their strength ensures that they can handle the weight and vibration produced by heavy equipment. This is particularly useful in settings where precision is paramount, such as CNC machining and robotics. You can learn more about machinery frame designs.

3. Racking and Storage Solutions

In warehouses and storage facilities, T-slot profiles can be configured into shelving and racking systems. This modular approach allows for easy reconfiguration as storage needs change over time. A table showcasing potential racking designs can illustrate this:

| Design Type | Features | Use Case |

|---|---|---|

| Standard Shelving | Adjustable heights, multiple levels | General storage |

| Heavy-Duty Racks | Reinforced for high loads | Industrial parts storage |

| Mobile Racking Systems | On wheels for easy relocation | Flexible storage solutions |

4. Protective Enclosures

Another key application is the construction of protective enclosures around machines. These structures enhance safety by preventing unauthorized access to moving parts while still allowing visibility. Explore enclosure solutions.

5. Automation Systems

The adaptability of T-slot profiles makes them ideal for automation projects. They are commonly used in conveyor systems, assembly lines, and robotic arms, allowing quick adjustments to meet evolving production demands. Detailed insights on automation setups can provide further examples.

6. DIY Projects and Home Improvement

For DIY enthusiasts, T-slot profiles are a perfect choice for personal projects ranging from furniture to home improvement solutions. Their ease of assembly means that even those without welding skills can create robust structures. DIY project ideas often showcase innovative uses of these profiles.

By understanding the diverse applications of aluminium T-slot profiles, you can better assess how they can meet your project requirements.

Where Can You Source High-Quality Aluminium T-Slot Profiles Locally?

Are you looking for reliable local sources to purchase high-quality aluminium T-slot profiles? Here’s how you can find the best options to meet your project needs!

To source high-quality aluminium T-slot profiles locally, consider local manufacturers, distributors, specialty hardware stores, and online directories. Attend trade shows and seek recommendations from your network for reliable suppliers.

Understanding Local Sourcing Options

When sourcing high-quality aluminium T-slot profiles locally, it’s essential to identify the most relevant suppliers in your area. These may include local manufacturers, distributors, and even specialty hardware stores that cater to industrial needs.

Engaging with local suppliers can provide several advantages such as reduced shipping costs and quicker turnaround times. Additionally, you can often inspect the materials before purchase, ensuring quality meets your standards.

To help you navigate your options, consider the following:

| Supplier Type | Description | Benefits |

|---|---|---|

| Local Manufacturers | Companies that produce T-slot profiles on-site. | Customization and direct communication. |

| Distributors | Wholesalers that carry various brands of aluminium profiles. | Wide selection and competitive pricing. |

| Specialty Hardware Stores | Retailers focused on providing materials for DIY and industrial projects. | Accessibility and immediate availability. |

Utilizing Online Directories

Online directories are a fantastic resource for finding local suppliers of aluminium T-slot profiles. Websites like ThomasNet or Alibaba allow you to filter by location and product type.

You can also search for local suppliers on platforms like Google Maps or Yelp to read reviews and see customer ratings, helping you make an informed decision.

Trade Shows and Industry Events

Attending trade shows is another effective way to source T-slot profiles locally. Events like the International Manufacturing Technology Show provide opportunities to meet manufacturers face-to-face, ask questions, and even negotiate deals directly.

These events often showcase the latest products and technologies, giving you insights into the best options for your needs. Moreover, networking with other professionals can lead to valuable recommendations for suppliers.

Recommendations from Your Network

Don’t underestimate the power of recommendations from your professional network. Reaching out to colleagues or industry contacts can yield leads on reliable suppliers. Many businesses have established long-term relationships with their suppliers, which can benefit you in terms of quality assurance and trust.

Consider asking questions like:

- Who have they sourced materials from?

- What was their experience with product quality?

- Were there any issues with delivery?

By leveraging these insights, you can make a more informed choice when selecting a supplier for your T-slot profiles.

Environmental Considerations

Given the increasing importance of sustainability, sourcing from suppliers who prioritize environmentally friendly practices is crucial. Look for manufacturers that use recycled aluminium or adhere to green certification standards. This not only supports local businesses but also aligns with your values as a conscientious entrepreneur.

By taking these steps, you can effectively find high-quality aluminium T-slot profiles locally that meet your specific needs for durability and design.

How Do Aluminium T-Slot Profiles Compare to Other Framing Systems?

Aluminium T-slot profiles have gained popularity due to their unique properties. But how do they stack up against traditional framing systems like welded steel? Let’s explore the key comparisons.

Aluminium T-slot profiles offer a lightweight, modular, and cost-effective alternative to traditional framing systems like welded steel, balancing strength and ease of assembly for versatile applications.

Overview of Framing Systems

When comparing aluminium T-slot profiles to other framing systems, it’s essential to consider various factors, including strength, weight, cost-effectiveness, and ease of assembly. Let’s delve into these aspects to provide a clearer picture.

Strength and Durability

Aluminium T-slot profiles are known for their high strength-to-weight ratio. They distribute loads evenly thanks to their geometry. Here’s a brief comparison:

| Framing System | Strength | Weight | Durability |

|---|---|---|---|

| Aluminium T-Slot | High | Light | Excellent |

| Welded Steel | Very High | Heavy | Good |

| Extruded PVC | Low | Light | Fair |

While welded steel offers superior strength, its weight can be a disadvantage in applications requiring mobility or frequent reconfiguration. In contrast, aluminium’s lightweight nature allows for easy handling without compromising too much on strength.

Cost-Effectiveness

From a cost perspective, aluminium T-slot profiles can be more economical in the long run. While the initial investment may be higher than some alternatives, the ease of assembly and reduced labor costs contribute to overall savings. Consider the following:

- Reduced Labor Costs: Since T-slot profiles don’t require welding or drilling, you save on labor expenses. Learn more about labor costs.

- Reusability: Components can be easily reconfigured for different projects, minimizing waste and the need for new materials.

Ease of Assembly

One of the standout features of aluminium T-slot profiles is their user-friendly assembly. Unlike welded steel, which often requires specialized tools and skills, T-slot profiles use standard fasteners:

- Fasteners like T-nuts and bolts make assembly straightforward.

- The modular design allows for quick adjustments and reconfiguration.

For those interested in DIY projects or small-scale manufacturing, this ease of assembly can significantly reduce project timelines. Explore DIY assembly tips.

Applications and Versatility

Aluminium T-slot profiles are widely applicable across various industries:

- Manufacturing: Used for machine frames and automation systems.

- Retail: Ideal for customizable displays and shelving.

- Office Design: Perfect for modular workstations.

Their versatility contrasts with other systems that may be limited in application due to rigidity or weight constraints. Check out versatile applications.

Environmental Considerations

As sustainability becomes increasingly important, it’s worth noting that aluminium is recyclable, making T-slot profiles an environmentally friendly option compared to other materials that may not offer the same sustainability features. This is crucial for businesses like David’s, which prioritize eco-friendly practices in their procurement. Discover green building materials.

Conclusion

Aluminium T-slot profiles are modular, lightweight components designed for easy assembly of customizable structures, offering strength and cost-effectiveness in diverse engineering applications.