Aluminium Profiles Quality Tests?

I once inspected a batch of CNC-cut aluminium profiles that looked perfect visually—but they failed tensile tests under load. That reminded me how critical proper testing is for quality assurance.

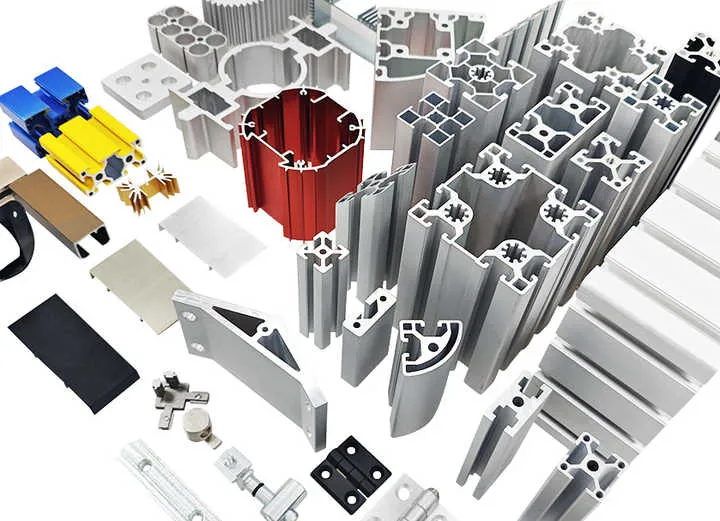

Quality testing for aluminium profiles must cover mechanics, dimensions, coatings, and more to ensure safety and performance.

Let’s explore the key quality tests, tensile strength measurement methods, dimensional tolerances, and coating evaluations.

What are the key quality tests for aluminum profiles?

Aluminium profile quality is validated through mechanical tests, dimensional checks, surface evaluations, coating integrity, and performance under environmental stresses.

Core quality tests include tensile testing, hardness checks, fatigue analysis, dimensional inspection, coating adhesion and corrosion testing, plus non-destructive testing.

Overview of Key Tests

| Test Type | Purpose | Standard or Method |

|---|---|---|

| Tensile & Yield Strength | Confirm mechanical properties under stress | ASTM B557, ISO 6892 |

| Hardness Test | Gauge heat treatment and material consistency | Rockwell, Brinell for aluminium |

| Fatigue & Cycle Testing | Simulate real-life loading and longevity | ISO 12107, fatigue machines |

| Dimensional Inspection | Ensure profile matches CNC specifications | CMM, laser scanning, gauges |

| Coating Adhesion | Check coating bond to substrate | ASTM D3359 tape test |

| Corrosion Resistance | Test coatings in harsh environments | Salt spray (ASTM B117), humidity, cyclic tests |

| Non-Destructive Testing | Detect hidden anomalies like voids or cracks | Eddy current, ultrasonic |

| Surface Quality Check | Assess finish, flatness, and surface defects | Visual inspection, gloss meters, profilometers |

Each test addresses part of the profile’s performance. Failure in any can lead to part rejection or recall.

Why Each Test Matters

- Mechanical strength tests ensure reliability under forces.

- Hardness and fatigue tests reveal how profiles will last under repeated stress.

- Dimensional checks guarantee parts fit assemblies.

- Coating and corrosion tests ensure long-term appearance and resistance.

- Non-destructive inspection detects internal flaws without wasting material.

I had a case where profiles passed visual checks but a hidden void found by ultrasonic testing led to cracking in application. We improved die quality after that test.

How is tensile strength measured for extrusions?

Tensile strength tests measure how much force an extrusion can handle before breaking or yielding.

Tensile tests use standardized samples cut from extrusions and pulled in a test machine to measure yield strength, ultimate tensile strength, and elongation.

Tensile Test Procedure

-

Sample Preparation

- Cut “dog-bone” shaped samples from extrusion or machined test bars.

- Samples must follow specific gauge length and cross-section.

-

Mounting in Test Machine

- Secure sample between hydraulic grips in a tensile tester (e.g., Zwick or Instron).

- Apply force to pull the sample.

-

Test Execution

- Pull at constant strain rate until sample yields and then breaks.

- The machine records stress vs strain curve.

-

Result Extraction

- Yield strength (0.2% proof): Stress at which plastic deformation begins.

- Ultimate tensile strength (UTS): Peak stress before break.

- Elongation at break: Measures ductility.

-

Standards to Use

- ASTM B557, ISO 6892 specify sample size, speed, conditions.

- Results help confirm alloy temper, heat treatment, and extrusion quality.

Key Metrics

| Metric | What It Tells Us |

|---|---|

| Yield Strength | Pressure before permanent deform |

| UTS | Maximum tensile load capacity |

| Elongation (A%) | Ductility and resistance to breaking |

If the profile fails yield strength requirements, it may not hold structural loads. Too low elongation means it can crack under bending or shock.

In one project, a misplaced tempering process left profiles below required yield strength. We caught the issue before assembly thanks to tensile testing and avoided a safety hazard.

What dimensional tolerances are standard for CNC aluminum profiles?

Dimensional tolerance ensures the profile fits with other parts after CNC machining. Tighter tolerances mean precise assembly but higher machining effort.

Standard CNC machined profiles follow ISO 2768 or customer-specific specs with general tolerances from ±0.1?mm to ±0.02?mm depending on size and feature class.

Size Tolerance Standards

| Dimension Range (mm) | ISO 2768 mTolerance | ISO 2768 fTolerance | Typical CNC Range |

|---|---|---|---|

| Up to 10 mm | ±0.1 mm | ±0.05 mm | ±0.02–0.05 mm |

| 10–100 mm | ±0.2 mm | ±0.1 mm | ±0.05–0.1 mm |

| 100–300 mm | ±0.3 mm | ±0.15 mm | ±0.1–0.2 mm |

| 300–1000 mm | ±0.5 mm | ±0.2 mm | ±0.2–0.3 mm |

- General tolerance (m): Suitable for non-critical dimensions, ±0.1–0.3?mm.

- Fine tolerance (f): For critical mating surfaces, ±0.02–0.1?mm.

Checking Methods

- CMMs measure part in 3D for geometric accuracy.

- Laser scanners capture shape and flatness, ideal for complex profiles.

- Calipers and height gauges work for simpler checks.

Examples of Critical Tolerance Zones

- Mating holes: ±0.02?mm

- Slot width: ±0.05?mm

- Surface flatness: < 0.05 mm per 100 mm

- Perpendicularity: ±0.1°

In a medical device part I checked, holes off by 0.1?mm stopped assembly. We updated our CNC setup to hold ±0.05?mm tolerance and solved the problem.

How are coatings tested for adhesion and corrosion resistance?

Coating quality matters just as much as mechanical strength. It affects longevity, appearance, and resistance in harsh environments.

Adhesion tests like cross-hatch tape pull verify coating bond to aluminium. Corrosion tests like salt spray use aggressive environments to assess durability of coated samples.

Adhesion Testing Procedure

- Cross-Hatch Cut

- Use sharp blade to make 6–11 parallel cuts in a grid, spaced at 1–2?mm.

- Apply and Peel Tape

- A pressure-sensitive tape goes over cuts.

- Tape pulled off quickly at 60° angle.

- Evaluate

- Grade from 0 (no flaking) to 5 (significant coating removal).

- Standards: ASTM D3359, ISO 2409.

Good adhesion = no coating removal after tape pull. Poor adhesion flags prep or curing problems.

Corrosion Testing Procedure

-

Salt Spray (ASTM B117)

- Panels are sprayed with salt fog for 96 hours or more.

- Check for rust, blistering, peeling at intervals.

-

Cyclic Corrosion

- More realistic weather cycles: salt spray→dry heat→humidity.

- Tests coating breakdown over longer cycles.

-

Bubbling & Blister Tests

- Immerse in water for several days. Evaluate blisters along edges or scribe lines.

Coating Types Checked

- Anodizing (Type II or III, architectural or hard anodize)

- Powder coatings (thermoset)

- Wet paints or liquid coatings

Surface Tests

- Gloss meter checks shine consistency

- Micrometer measures thickness (minimums of 15?μm for powder coat or 10?μm anodize)

- Profilometer ensures surface texture is even

In one marine hardware project, coating peeled at the edge after 200 hours salt spray. Adjusting pre-treatment and raising coating thickness from 12 to 20?μm fixed adhesion issues.

Conclusion

Comprehensive testing of aluminium profiles ensures they meet design and performance demands. Key tests include tensile tests, hardness, fatigue, dimensional checks, coating adhesion, corrosion testing, and non-destructive inspection.

Tensile strength is measured with standard dog-bone samples and test machines. Dimensional tolerances range from ±0.02?mm to ±0.3?mm depending on precision need. Coatings—including anodizing and powder coat—must pass adhesion tape tests and salt spray exposure to ensure longevity.

Thorough testing avoids failures in use, protects brand quality, and supports safe, reliable aluminium products.

True/False Questions

A cross?hatch tape adhesion test is used to evaluate coating adhesion to aluminumTrue

The cross?hatch cut followed by tape pull is a standardized method (ASTM D3359) to check adhesion.

ISO 2768 fine tolerance (f) allows only ±0.3?mm dimensional variationFalse

ISO 2768f is stricter, with tolerances around ±0.02–0.1?mm depending on feature size, not ±0.3?mm.