How Many Times Can an Aluminium Profile Extrusion Die Be Used and How Is Its Lifespan Calculated?

Have you ever wondered how long an aluminum extrusion die can actually last? It’s a question that has crossed my mind many times during my years in manufacturing.

The lifespan of an aluminum profile extrusion die varies widely based on several factors including the quality of the die steel, design and manufacturing technology, maintenance practices, and operational conditions. While no fixed usage count exists, high-quality dies can endure hundreds of thousands of uses.

Let’s dive into the various factors that affect the lifespan of these essential tools and discover how we can enhance their longevity.

High-quality die steel can extend die life to hundreds of thousands of uses.True

Superior steel offers hardness and wear resistance, enhancing longevity.

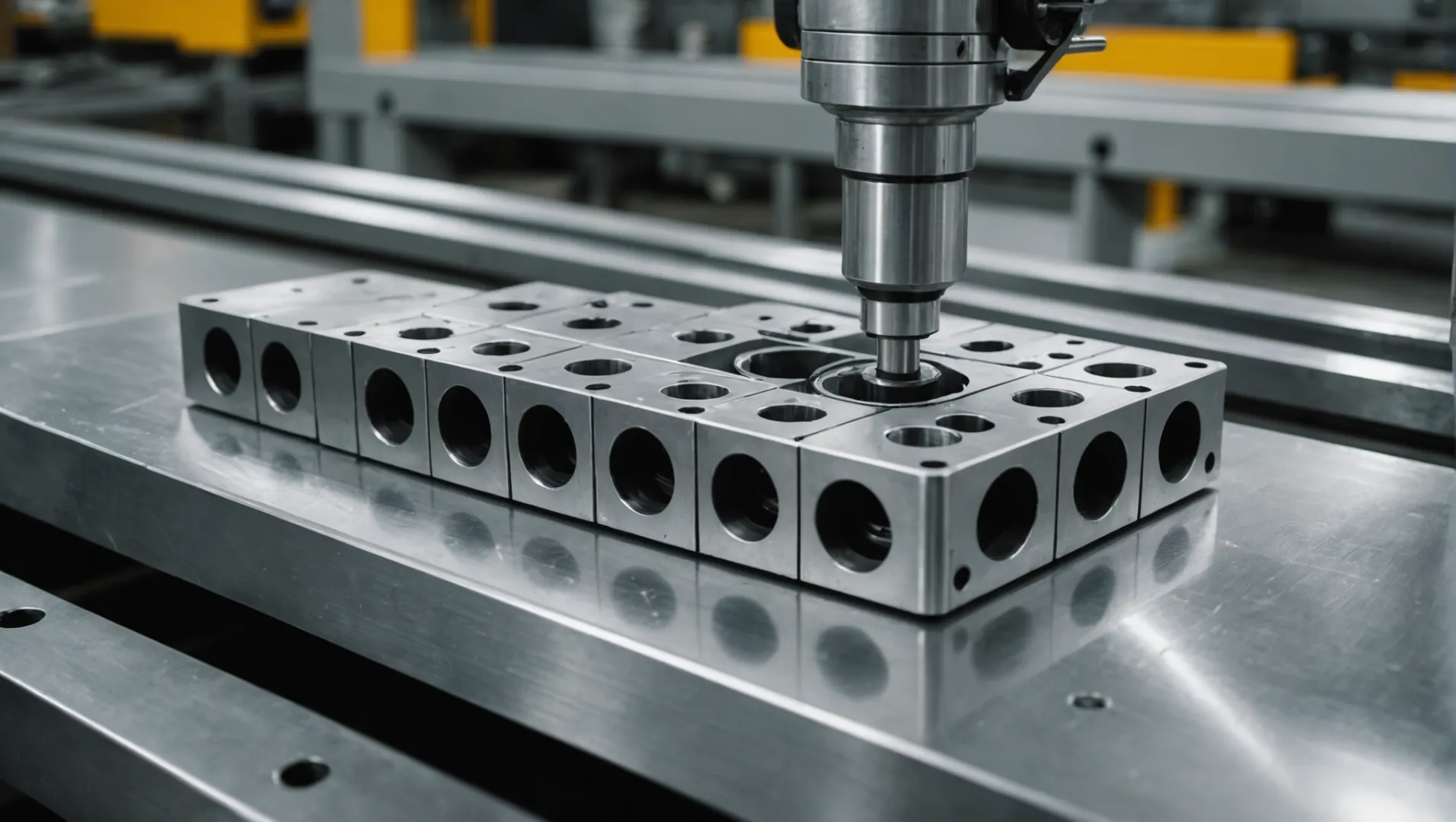

What Factors Affect the Lifespan of an Aluminium Extrusion Die?

Understanding the factors influencing the lifespan of an aluminium extrusion die can significantly optimize production and reduce costs.

The lifespan of an aluminium extrusion die is influenced by die steel quality, design and manufacturing technology, maintenance practices, and operational processes. High-quality steel and proper maintenance can significantly extend its lifespan, while poor quality materials and inadequate care reduce it.

Quality of Die Steel

The choice of die steel is a critical factor in determining the lifespan of an aluminium extrusion die. High-quality steel offers superior hardness, strength, and wear resistance, which are essential for withstanding the intense pressure and friction during the extrusion process. On the other hand, opting for cheaper, inferior steel can lead to rapid wear, deformation, and even cracking of the die. For instance, studies on steel grades1 highlight how different compositions can affect durability.

Design and Manufacturing Technology

A well-thought-out design and advanced manufacturing technology are paramount. Innovative designs can help distribute stress evenly, preventing stress concentration that might lead to cracks or breaks. Additionally, precise manufacturing ensures dimensional accuracy and high surface quality, which minimize wear during operation. For example, design innovations2 that incorporate rounded corners instead of sharp edges can reduce stress concentrations.

Maintenance Practices

Routine maintenance is vital for prolonging the life of an extrusion die. Regular cleaning, lubrication, and treatments such as nitriding can prevent rust, corrosion, and excessive wear. A proactive approach to maintenance not only extends the lifespan but also improves the reliability and efficiency of the die. Maintenance checklists3 can provide a structured approach to keeping dies in optimal condition.

Operational Processes

The methods used during production also play a significant role in determining die longevity. Ensuring that operational parameters such as temperature and pressure are within optimal ranges can reduce unnecessary stress on the die. Moreover, appropriate management of the extrusion process ensures that forces exerted on the die are evenly distributed, thereby enhancing its stability and reliability. Process optimization techniques4 offer valuable insights into achieving this balance.

Management and Storage

Finally, effective management and storage of extrusion dies are crucial. Proper storage conditions prevent environmental damage like rust or warping, while scientific management practices ensure that dies are used and maintained according to best practices. This holistic approach can be critical in avoiding premature die failure. Management strategies5 for tooling equipment often include guidelines for storage and handling.

By considering these factors collectively, manufacturers can significantly extend the service life of their aluminium extrusion dies, leading to better product quality and improved cost efficiency.

High-quality steel extends die lifespan.True

High-quality steel offers superior hardness and wear resistance, extending die life.

Poor maintenance increases die lifespan.False

Inadequate maintenance leads to rust and wear, shortening die lifespan.

How Does Die Steel Quality Impact Die Longevity?

The quality of die steel is a critical determinant of the lifespan of dies used in aluminum profile extrusion, affecting durability and performance.

High-quality die steel enhances die longevity by providing superior hardness, strength, and wear resistance, essential for withstanding the pressures and frictions in production.

The Role of Hardness in Die Longevity

High-quality die steel typically exhibits greater hardness, which directly impacts the die’s ability to withstand abrasive conditions. In aluminum extrusion, the die is subjected to intense pressure and friction. A harder steel resists deformation and wear, maintaining its structural integrity over more cycles. For instance, Enterprise B’s investment in high-quality steel led to their dies lasting hundreds of thousands of uses.

Strength and Wear Resistance

Die steel with superior strength and wear resistance can endure the rigors of aluminum extrusion. These attributes prevent common issues like cracking and deformation that occur with lower quality steel. In production environments, this means fewer interruptions and reduced replacement costs. As seen with Enterprise A, opting for cheaper steel resulted in rapid wear and early die failure.

Impact on Surface Finish and Dimensional Accuracy

The quality of die steel also affects the surface finish and dimensional accuracy of extruded products. A high-quality die maintains its precision longer, reducing defects and enhancing product consistency. This not only extends the life of the die but also improves the overall quality of production.

| Steel Quality | Expected Lifespan | Performance Characteristics |

|---|---|---|

| High-Quality | Hundreds of Thousands | Superior hardness and wear resistance |

| Low-Quality | Few Thousand Uses | Prone to deformation and cracking |

Real-World Applications

In practical scenarios, the impact of die steel quality is evident. Consider enterprise case studies6 showing how material choice affects operational longevity. By investing in premium steel, companies not only improve die longevity but also enhance production efficiency.

Choosing the Right Die Steel

Selecting the right die steel involves balancing cost against potential savings in maintenance and replacements. For many manufacturers, the initial higher investment in quality steel pays off through extended die life and improved product quality. When evaluating options, consider consulting with experts on die material selection7 to ensure optimal performance.

High-quality die steel extends die lifespan significantly.True

Superior hardness and wear resistance in high-quality steel increase longevity.

Low-quality die steel offers better surface finish consistency.False

High-quality steel maintains precision, enhancing product consistency and finish.

What Role Does Maintenance Play in Extending Die Life?

Regular maintenance is the unsung hero of extending die life, safeguarding against premature wear and ensuring consistent production quality.

Maintenance plays a pivotal role in prolonging die life by preventing rust, corrosion, and wear. Regular cleaning, lubrication, and surface treatments like nitriding can drastically enhance the durability and functionality of extrusion dies, thus maximizing production efficiency.

The Importance of Regular Cleaning and Inspection

Routine cleaning is crucial for maintaining the die’s surface quality. Contaminants such as debris and residue can accumulate over time, leading to increased friction and wear. Regular cleaning helps to eliminate these risks, ensuring smooth operation and prolonging the die’s lifespan.

Inspection goes hand-in-hand with cleaning. Frequent checks allow for the early detection of potential issues such as cracks or deformations. Identifying these problems early can prevent costly repairs or replacements later. Explore maintenance inspection techniques8 that are effective for different types of extrusion dies.

Lubrication: The Lifeline of Longevity

Proper lubrication reduces friction between moving parts, which is essential in preventing excessive wear and tear. Using the right type of lubricant tailored to your specific die material and operational conditions can significantly extend die life. Learn about optimal lubrication practices9 for extrusion dies.

Surface Treatments: Enhancing Durability

Surface treatments such as nitriding add a protective layer to the die, improving hardness and resistance to wear. This treatment is particularly beneficial for dies subjected to high-pressure conditions, as it can withstand greater stress and minimize the risk of surface damage.

Scheduled Maintenance Routines

Establishing a scheduled maintenance routine is vital. This schedule should include cleaning, lubrication, and any necessary surface treatments at regular intervals. Consistency in maintenance ensures that all aspects of the die’s performance are optimized, ultimately leading to an extended service life.

Implementing a comprehensive maintenance strategy not only preserves the integrity of the dies but also enhances the overall efficiency and cost-effectiveness of production operations.

Incorporating these maintenance practices into your standard operating procedures can yield significant long-term benefits.

Regular maintenance prevents die corrosion.True

Maintenance, including cleaning and lubrication, prevents rust and corrosion.

Surface treatments reduce die wear significantly.True

Treatments like nitriding enhance hardness and wear resistance.

How Can Design and Manufacturing Technology Improve Die Usage?

In the world of aluminum extrusion, leveraging advanced design and manufacturing technology is pivotal in maximizing die efficiency and longevity.

Design and manufacturing technology can improve die usage by enhancing precision, reducing stress concentrations, and optimizing material flow. Innovative designs and cutting-edge manufacturing techniques ensure better performance and extended service life of extrusion dies.

Advanced Design Strategies

Implementing advanced design strategies10 can significantly enhance die performance. One key aspect is minimizing stress concentration. By optimizing the die’s geometry to distribute stress evenly, you can prevent premature failure. For instance, avoiding sharp corners or edges in the die design helps in reducing stress points that could lead to cracking.

Another effective design approach is to incorporate rounded corners with sufficient radius to allow smooth material flow and reduce wear. A well-designed mold will have less ejection force and minimal surface strain on concave mold cavities.

Cutting-Edge Manufacturing Techniques

The manufacturing phase is equally crucial in improving die usage. Precision machining11 and high-quality surface finishes contribute to better durability. Utilizing CNC technology for intricate designs ensures accuracy and consistency, which are vital for maintaining the die’s structural integrity during repeated use.

Material Selection and Treatment

Selecting high-grade materials such as tool steel with superior hardness and wear resistance is critical. Advanced manufacturing processes also involve heat treatments to enhance the material properties, which helps in achieving a longer service life for dies.

Additionally, surface treatments like nitriding can improve wear resistance and reduce friction during extrusion.

| Technique | Benefits |

|---|---|

| CNC Machining | Enhances precision and consistency in die production |

| Heat Treatment | Increases material strength and hardness |

| Surface Treatments | Reduces wear and extends service life |

Maintenance as a Complementary Practice

While design and manufacturing technology lay the foundation, regular maintenance12 complements these efforts by ensuring dies remain operational over time. Routine inspections, cleaning, and lubrication prevent deterioration and maintain optimal performance.

Technology Integration for Process Optimization

Integrating modern technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) can streamline the entire die production process. These technologies allow for simulations that predict wear patterns, enabling proactive adjustments to design before production begins.

By adopting a holistic approach that combines innovative design with sophisticated manufacturing techniques, companies can significantly improve their die usage, resulting in enhanced productivity and reduced downtime.

Advanced designs reduce stress in extrusion dies.True

Optimizing die geometry distributes stress evenly, preventing failure.

CNC machining decreases die production precision.False

CNC machining enhances precision and consistency in die production.

Conclusion

By focusing on quality materials, thoughtful design, and diligent maintenance, manufacturers can significantly extend the life of their aluminum extrusion dies.

-

Explore different steel grades to enhance die durability.: From 2023, we found better steel, modified BPM series steel, the cost is higher, compared with 2311, but better stability, higher hardness (HRC38-40), after … ↩

-

Discover how design improvements can reduce stress concentration.: This paper proposes an innovative layout design approach using a geometry based bearing length design methodology to minimise variations in exit velocity. This … ↩

-

Learn essential steps for regular die maintenance.: A flat extrusion die for film, sheet, or coating must be disassembled for standard maintenance–a procedure called a split and clean. ↩

-

Find ways to optimize operational processes for better die longevity.: This research evaluates the effect of extrusion variables on the quality and extrudate characteristics and sensory acceptability of wheat-tiger nut pasta. ↩

-

Understand best practices for managing and storing tooling equipment.: Key strategies for effective equipment management include implementing asset-tracking software, creating regular maintenance checklists, … ↩

-

Explore case studies demonstrating how steel quality affects operational longevity.: One of the primary benefits of high-quality tool and die steel is the reduction in maintenance and replacement costs. High-quality steels are … ↩

-

Guidance on choosing optimal die materials for better performance.: The authors discuss the most important aspects of material selection for extrusion tooling, including temperature, cycle time, and more. ↩

-

Discover various methods for inspecting extrusion dies effectively.: Before lifting the die, it is a good time to inspect the eye bolts. Make sure they are not bent or cracked, and if they are, do not use them … ↩

-

Learn about lubrication methods that enhance die longevity.: The two main reasons for applying die lubricant are to reduce friction and dissipate heat. Heat can build up between the tool surface and … ↩

-

Explore how advanced designs minimize stress concentrations for better die longevity.: Surface engineering: Advanced surface treatments and coatings like nitriding, chromium plating, or hard coating enhance die performance, … ↩

-

Learn how precision machining enhances die durability and performance.: After machining, tools and dies are heat treated to improve their mechanical properties and performance capabilities. Proper management of heating and cooling … ↩

-

Understand why consistent maintenance prolongs the lifespan of extrusion dies.: A flat extrusion die for film, sheet, or coating must be disassembled for standard maintenance–a procedure called a split and clean. ↩