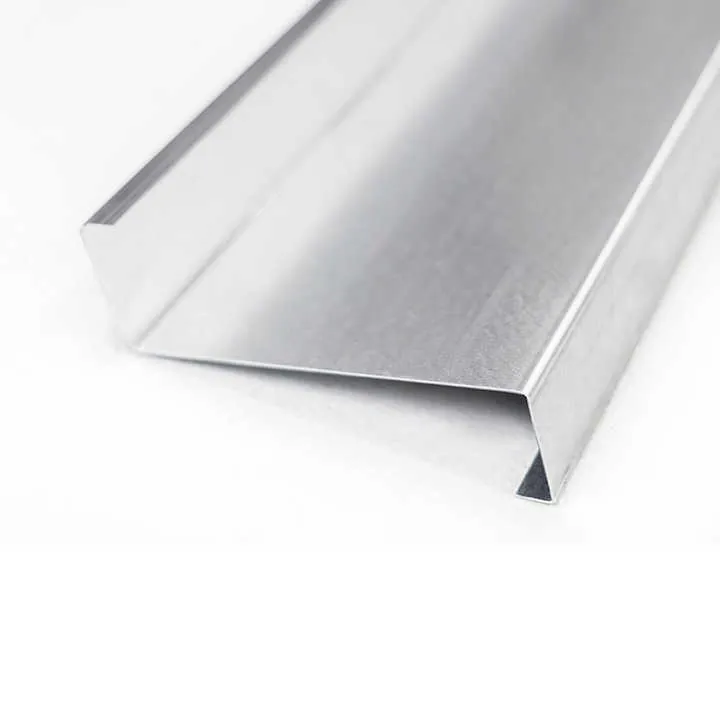

Aluminium Edging Strip: Aesthetic & Practical Combination?

I have installed aluminium edging strips in many projects. I know they must look good and last under stress.

Can aluminium edging strip combine beauty and function well? I will share how design, durability, coating, and installation fit together.

What design trends pair well with aluminum edging strips?

I once matched edging strips to modern interiors. That taught me how trends shape material use.

Aluminium edging pairs best with minimalist, industrial, and Scandinavian design trends.

I explain each trend and why aluminium suits them:

Design Styles Table

| Design Trend | Why It Works With Aluminium Edging |

|---|---|

| Minimalist | Clean lines match aluminium’s sleek profile |

| Industrial | Metal feel fits raw materials like concrete and wood |

| Scandinavian | Light tones and natural feel complement matte finishes |

| Modern Boho | Mix of textures balanced by sleek metal edge detail |

| High-tech | Sharp lines and precision give futuristic look |

Minimalist and modern

I like minimalist spaces. They use white walls, simple furniture, little clutter. Aluminium edging adds a fine accent. It gives crisp transition between surfaces without visual noise.

Industrial and loft styles

In industrial spaces, raw materials rule. Metal beams, exposed ductwork, concrete floors. Aluminium edging joins the look. It blends in but adds refinement at edges.

Scandinavian trend

This style favors light woods, neutral palettes, and clean forms. Anodised or powder-coated aluminium can match grey, beige, even black tones. It fits softly.

Modern boho mix

Boho mixes natural and modern. Rugs, plants, wood. Aluminium edging adds a modern note. It balances softness with structure.

High-tech and smart home

Smart homes use screens, lights, tech features. Aluminium edging keeps edges tidy. It matches tech devices and recessed installations.

I also note finishes:

- Brushed aluminium: soft sheen, hides scratches

- Anodised colors: grey, black, bronze for accent

- Powder-coat: pastel or bold colors, brand identity

Designers may use bespoke machining or laser-cut grooves to coordinate with panel lines or logos. That adds custom detail.

Aluminium edging strips suit minimalist and industrial designs due to sleek metal lines.True

The clean, linear profile of aluminium edging enhances minimalist and industrial aesthetics without visual clutter.

Aluminium edging is unsuitable for warm interior styles.False

With appropriate finishes like wood-look powder coat, aluminium edging can complement warm and natural interior styles.

How resilient are aluminum edging strips under regular wear and tear?

I once reviewed a school hallway. Aluminium edging held up well under heavy foot traffic. That showed its practical strength.

Aluminium edging is strong enough for moderate to heavy use, though it can dent if hit hard.

Durability Metrics Table

| Property | Aluminium Edging Strip |

|---|---|

| Impact resistance | Medium – can dent under hard impacts |

| Bend and flex durability | Good – flexible alloys resist cracking |

| Wear from foot traffic | Minimal if properly fixed |

| Scratch resistance | Varies with finish; brushed hides minor marks |

| Maintenance | Easy to clean, no rust |

Impact and dent risk

Aluminium alloys like 6063-T5 are used. They resist bending and cracking. Yet, a strong impact from equipment may dent the strip. That said, dents are often cosmetic and behind doors or furniture they go unnoticed.

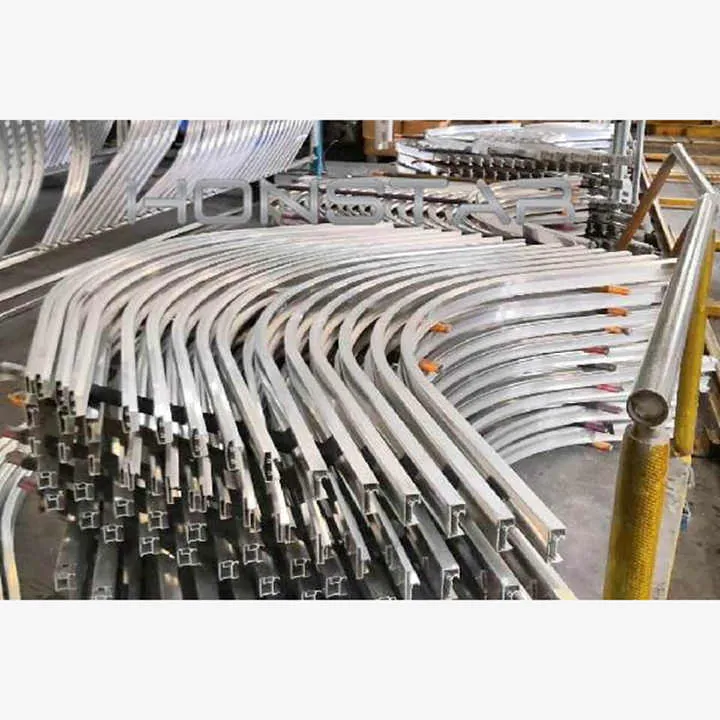

Flexibility and adaptation

The alloy allows bending around curves or angles. It stays stable even under repeated flex. That helps in dynamic spaces or where floor settling occurs.

Foot traffic wear

Installed at thresholds or edges, aluminium edging handles daily foot traffic well. There is little wear when edges are fixed and smooth.

Maintenance and wear

Cleaning with a damp cloth removes scuffs. Soft abrasives or mild detergents work. No rust forms. Coatings protect the surface. Maintenance is simple.

Long-term condition

With moderate use, aluminium edging lasts many years. In commercial spaces, it may show surface marks after 3–5 years but still functions well.

Aluminium edging strips hold up well with daily foot traffic.True

When installed correctly, aluminium edging shows minimal wear under regular use and is easy to clean.

Aluminium edging strips are prone to structural failure under normal use.False

Alloy strips like 6063-T5 resist cracking and deformation under normal foot traffic and light impacts.

What surface coatings improve aluminum trim durability?

I saw bare aluminium fail quickly outdoors. That led me to explore coating options for protection.

Anodizing, powder-coat, and wood-grain coatings boost aluminium trim durability and aesthetic longevity.

I detail key coatings:

Coating Types Table

| Coating Type | Durability Benefits | Visual Effects |

|---|---|---|

| Anodizing | Hard oxide layer resists corrosion and wear | Metallic colors, matte finish |

| powder-coat | Tough polymer layer; resists chipping and UV | Full color range |

| wood-grain transfer | Covers and protects; resists scratches | Wood look without wood issues |

| Electro-paint | Thin corrosion barrier; smooth, uniform layer | Glossy or satin finishes |

| Wax/oil seal | Extra corrosion protection for outdoor use | Invisible |

Anodizing details

Anodizing builds an oxide layer that is hard and durable. It resists wear, corrosion, and retains color. I use Type II for indoor color, Type III hard coat for heavy use. Colors include black, bronze, silver. Finish looks sleek and resists finger marks.

powder-coat details

This process applies polymer powder and bakes it. It creates a thick, durable shell. It resists chips, UV fading, and cleaning agents. It allows any color. I used it for orange safety edging in areas.

wood-grain film

Film wraps aluminium to mimic wood. It protects the metal and provides warm texture. I use it where wood feel is needed but wood can’t last. It resists scratches and humidity.

Electro-paint benefits

Electrophoretic deposition gives thin and uniform coating. It seals the aluminium and primes for powder-coat. Finish is smooth. It is often combined with other coatings.

Wax or oil seal

For aluminum used outdoors, an invisible wax or oil adds extra rust protection. This layer repels water and helps corrosion resistance, especially near coastal areas.

Choosing coating by use:

- Indoor decor: anodizing for sleek look

- Heavy traffic: hard coat anodize or powder-coat

- Outdoor or wet areas: powder-coat with seal

- Wood-design schemes: wood-grain film

Anodizing enhances aluminum trim’s wear resistance and corrosion protection.True

Anodized aluminium forms a hard oxide layer that protects against abrasion and corrosion.

Clear coat alone is enough for outdoor aluminum trim.False

A clear coat helps, but powder-coat or anodizing provide more resistance to UV, wear, and moisture.

Is installation of aluminum edging strip DIY-friendly?

I guided DIY teams to install edging. Most found it easy with basic tools. That encouraged me to support self-installation.

Installing aluminium edging strip is DIY-friendly if tools and instructions are used properly.

I outline the process step by step:

DIY Installation Table

| Step | DIY Task |

|---|---|

| Measuring and planning | Use tape and layout before cutting |

| Cutting aluminium | Use hacksaw, mitre saw, or circular saw with non-ferrous blade |

| Bending / profiling | Hand-bend inside curves; use brake press for tight angles |

| Surface finishing | Sand rough edges, wipe clean, apply sealant |

| Fixing to surface | Use screws, nails, or adhesive strips (double-side tapes) |

| Checking alignment | Ensure flush against edges and flat on surface |

| Final cleaning | Remove dust, polish, inspect |

Tools needed

- Tape measure, pencil

- Saw with a blade for aluminium

- File or sandpaper

- Drill and screws or adhesive

- Mounting block or use wood backing

Cutting tips

Mark precisely. Use aluminium-rated blade to avoid tearing. Deburr edges to prevent cuts and help finish stick.

Bending tips

Gentle curves: hand-bend slowly. Tighter bends: use bending block or jig. The material allows smooth curves without cracking.

Fixing methods

For wood subfloor: use screws every 150–200 mm. Countersink heads. For tile or concrete: use masonry anchors. For smooth surfaces: use double-side aluminum-rated tape. That avoids drilling.

Alignment

Press the strip firmly. Check it is flush. If uneven, loosen and adjust. Use blocks or wedges if needed to support before tightening.

Sealing

When edging meets different materials (e.g. tile/grout), run a thin silicone bead to prevent water infiltration.

Advantages for DIY

Lightweight and flexible. Clean installation with common tools. Coated surfaces resist handling marks. Edges snap on well if proper channel used.

Challenges

Long runs need straight cutting and alignment. Curves need care. Outdoor installers should seal ends to prevent water entry.

Overall I found DIYers usually succeed in one afternoon. Installation guides and videos help.

DIY installers can cut and fix aluminium edging with basic tools.True

Aluminium is lightweight and soft enough to be cut and installed with saws and screws common in DIY kits.

DIY installation of aluminium edging requires industrial equipment.False

Standard woodworking tools suffice for aluminum edging; only complex bends might need a press.

Conclusion

Aluminium edging strips balance design and practicality well. I have seen them enhance spaces, resist wear, and fit DIY use. Choose coatings based on use and finish for lasting results.