Anodizing Polished Aluminum Profiles: What Are the Benefits?

Leading paragraph:

I notice many engineers want shiny aluminum that lasts. They face corrosion, scratches, or fading.

Anodizing makes polished aluminum strong, corrosion resistant, and keeps the shine.

This article shows why this process is worth it.

What are the benefits of anodizing polished aluminum?

I often worry about aluminum becoming dull or damaged. Polished aluminum looks great at first. But exposure to weather and wear can ruin that look fast.

Anodizing adds a clear, hard layer to polished aluminum. That layer resists corrosion, wear, and fading.

Dive deeper: Why anodizing boosts performance

Anodizing is a controlled oxidation process. The aluminum is placed in an acid bath. An electric current passes through it. This builds a thick oxide layer on the surface. That layer is still part of the aluminum. It does not peel or flake like paint. It also seals and protects.

Hardness and scratch resistance

| Property | Untreated Polished Aluminum | Anodized Polished Aluminum |

|---|---|---|

| Surface hardness | Soft | Hard (cuticle-resistant) |

| Scratch resistance | Low | High |

| Wear from contact | High | Low |

Without anodizing, polished aluminum damages easily. With anodizing, the surface resists scratches and handles rough use.

Corrosion and chemical resistance

Polished aluminum may oxidize naturally. That dulls the shine over time. Anodizing adds a thicker oxide layer. This layer blocks corrosion from rain, humidity, and chemicals. That means the polished look lasts longer even outdoors or in industrial settings.

UV stability and UV fade protection

A polished aluminum surface can lose its luster from sun exposure. UV rays can damage it. But anodizing prevents direct exposure to UV rays. The oxide layer is stable and keeps the shine intact.

Lifespan and maintenance

Anodized polished aluminum can last decades with basic cleaning. Just mild soap and water. That cuts down on time and costs. It also keeps custom surfaces looking new longer.

Quiz time:

Anodizing creates a layer that peels off easily like paint.False

The anodized layer is integral to the aluminum and does not peel.

Anodizing helps prevent scratches and corrosion on polished aluminum.True

The oxide layer forms a hard, protective barrier.

How is polished aluminum surface prepared for anodizing?

I once polished aluminum parts in my workshop. They looked perfect. But skipping prep before anodizing caused dull spots. I had to refinish everything.

Preparation gives a spotless surface in the final part after anodizing.

Dive deeper: Steps in surface preparation

To anodize polished aluminum well, these steps are vital:

- Cleaning degrease – Use alkaline or solvent cleaners. This removes oils or machining residue.

- Desmut – Apply acids like nitric or sulfuric acid to remove metal residues from polishing. This gives a uniform base.

- Brightening (optional) – A mix of acids and heat enhances shine if needed.

- Polishing – Use abrasive pads or compounds. Start coarse then go fine. Finish with polishing paste.

- Final clean – Rinse with deionized water to leave no mineral stains.

- Dry and protect – Air dry in a clean area. Avoid dust. They go straight into anodizing tanks.

Each of these steps affects how the anodized surface looks:

- Cleaning makes sure no oils block oxide growth.

- Desmutting ensures no dark spots remain.

- Polishing controls mirror-like finish.

- Brightening adds depth and uniformity.

I once polished a custom sign. I skipped brightening. The anodized finish looked dull and uneven under showroom lights. It taught me prep is not optional.

Quiz time:

A final rinse with tap water is fine before anodizing polished aluminum.False

Tap water can leave mineral residue that shows up after anodizing; deionized water prevents spots.

Polishing before anodizing controls how shiny the final finish will be.True

The level of polish directly affects the reflectivity after anodizing.

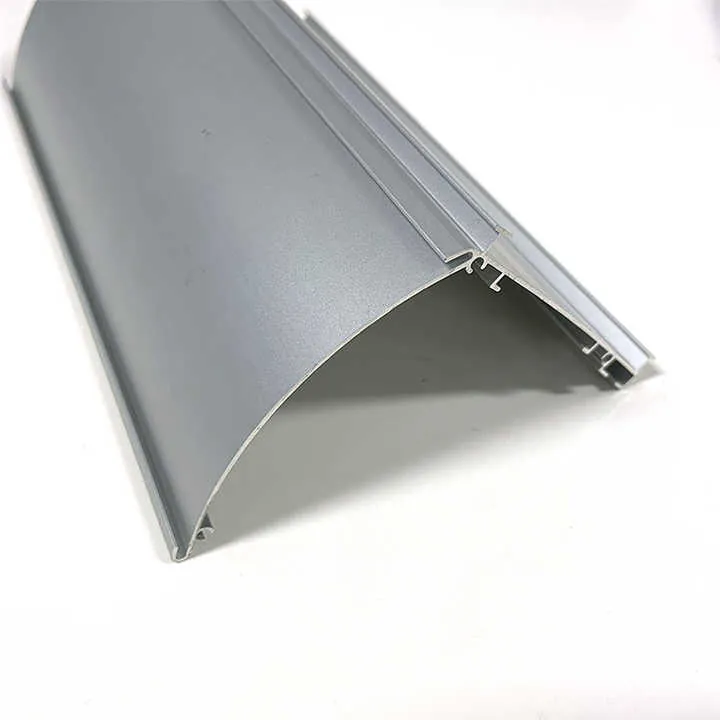

What types of finishes can anodized polished aluminum have?

I once designed parts for an architectural project. The client asked for a mirror shine. Another asked for a satin glow. Anodizing can give both.

Anodized polished aluminum can have matte, satin, mirror or even color-stained finishes.

Dive deeper: Finish options explained

Anodizing lets you choose how the aluminum looks after polish. Here are the main options:

Mirror (bright) finish

This is the most polished look. It gives a reflection like glass. To get it:

- Polish to 1200+ grit.

- Use brightening baths before anodizing.

- Anodize in a cold sulfuric bath.

- Seal quickly to avoid haze.

Applications: mirrors, decorative panels, luxury consumer products.

Satin finish

A soft glow, less mirror but still smooth. To create:

- Polish to ~800 grit.

- Use mild brightening.

- Use standard anodizing bath.

- Seal gently.

Applications: handles, trims, furniture profiles.

Matte/diffuse finish

Less shine, slight texture. To achieve:

- Polish to ~400–600 grit.

- Skip brightening.

- Use standard anodizing.

- Seal with matte sealers.

Applications: industrial parts, enclosures, tool surfaces.

Colored anodized finish

Dyes or metal salts added after anodizing create colors. Options include:

- Clear over color to retain shine.

- Mixed finishes. E.g., mirror shine center with satin borders.

- Two-tone designs (silver plus black, blue, bronze).

| Finish Type | Shine Level | Typical Use Cases |

|---|---|---|

| Mirror | High | Decorative panels, signs, high-end trims |

| Satin | Medium | Architectural trims, fixtures |

| Matte | Low | Industrial equipment, safety surfaces |

| Colored Anodized | Varies | Branded or design-focused products |

I once made a vehicle trim with mirror center and satin frame. It looked bespoke and durable. The client loved it.

Quiz time:

Colored anodizing always hides the polished shine.False

You can apply clear anodizing over color or mask areas to preserve shine.

Mirror anodizing requires brightening baths to enhance reflectivity.True

Brightening ensures a smooth, reflective surface before anodizing.

How long does anodized polished aluminum last?

I always get questions: how long will the shine last outside? I tested parts on my balcony and steel plant. Many hung on walls years later and still looked new.

Anodized polished aluminum lasts for decades with basic care and no coatings peeling.

Dive deeper: Lifespan, wear, and durability

Anodized polished aluminum lasts far longer than bare aluminum. The lifespan depends on:

- Anodic layer thickness

- Standard architectural: 10–25 microns

- Hardcoat: 25–100+ microns

| Anodic Thickness | Scratch Resistance | Outdoor Durability |

|---|---|---|

| 10–25 μm | Medium | 10–20 years in mild climates |

| 25–100+ μm | High | 20+ years in harsh conditions |

Thicker layers add durability, but cost more. Hardcoat is best for wear parts. Architectural thickness suits building facades.

Sealing method also matters:

- Hot water seal – forms boehmite layer. Good for corrosion, medium shine loss.

- Cold sealing – adds nickel acetate. Keeps shine better for mirror finishes.

- Organic seal – adds Teflon, fluoropolymers. Best chemical resistance.

Environmental and maintenance effects

- Coastal salt air speeds corrosion. Use thicker coatings and frequent washing.

- High abrasion (industrial plants) needs hardcoat and film protection.

- Regular cleaning keeps shine and removes contaminants.

I once saw an anodized railing outdoors for 15 years. It still held shine in areas, though edges were softer. The thicker hardcoat held up best.

Typical warranties

Many firms offer 10–25 year warranties for architectural grade finishes. That confirms longevity.

Quiz time:

Thicker anodic layers always reduce reflectivity significantly.False

Hardcoat can maintain good reflectivity but is optimized for durability.

Sealing in hot water adds corrosion resistance but may dull a mirror finish.True

Hot water sealing forms a stable layer but lowers reflectivity slightly.

Conclusion

Anodizing polished aluminum protects shine, boosts durability, and offers many look options. With the right prep and control, finishes can last decades. It fits architectural, industrial, and design uses.