What is a Turning Heat Sink?

When your devices overheat, performance drops fast. But not all heat sinks are built the same. Have you heard of "turning heat sinks"?

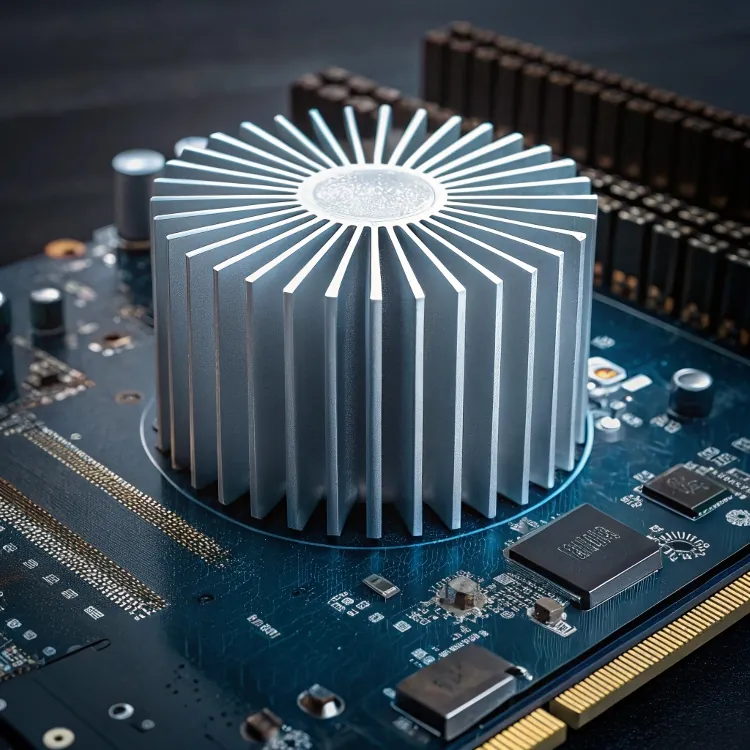

A turning heat sink is a type of thermal dissipation component manufactured using CNC turning instead of traditional extrusion or milling, offering improved cylindrical precision and material usage.

If you’re sourcing CNC parts for electronics or automation projects, understanding turning heat sinks can give you a performance and design edge.

What is a turning heat sink and how does it differ from standard heat sinks?

When people think of heat sinks, they often picture large aluminum blocks with fins cut through them. These are typically made with extrusion or milling. But turning heat sinks are different.

Turning heat sinks are made using CNC lathes1 that rotate the material, allowing the formation of round and symmetrical shapes, ideal for specific compact or axial cooling designs.

Turning heat sinks have radial designs instead of traditional vertical fins. They’re often used in high-density electronic assemblies or circular enclosures where traditional shapes won’t fit.

Key Differences Between Turning and Standard Heat Sinks

| Feature | Turning Heat Sink | Standard Heat Sink |

|---|---|---|

| Shape | Round or Cylindrical | Rectangular or Flat |

| Manufacturing Method | CNC Turning | CNC Milling / Extrusion |

| Typical Application | LED lights, small enclosures | Power modules, open-frame designs |

| Fin Orientation | Radial | Linear / Parallel |

These differences affect not only shape but also how heat is dispersed. Turning heat sinks can radiate heat more evenly from the center outward, which is useful in compact layouts.

Additionally, turning allows more flexibility in integrating functional features like threading, grooves, or cavities without needing secondary operations. This is especially useful for products with integrated mounting or alignment requirements.

Why use turning in heat sink manufacturing for aluminium CNC parts?

Traditional extrusion limits design. When I worked with a smart lighting startup, we found that round LED enclosures made it nearly impossible to mount standard heat sinks inside.

CNC turning enables precise machining of circular heat sinks, offering better thermal integration2 for confined or symmetrical layouts and maximizing material efficiency.

Turning allows me to create designs with smooth curved fins or integrated threaded holes—all in a single machine setup. This cuts secondary processing, saving both time and money.

Benefits of CNC Turning for Heat Sink Fabrication

- Efficiency: Turning creates a part in fewer steps.

- Symmetry: Ideal for products needing radial airflows like fans.

- Material Savings: No overcutting or excess material waste.

- Surface Finish: Turning can achieve smooth finishes ideal for anodizing.

- Repeatability: CNC systems ensure consistent parts across batches.

I’ve also noticed that turned parts produce fewer burrs compared to milled ones. That means less post-processing and more consistent performance. This can speed up the entire supply chain and reduce rework.

In a recent project, we created a custom circular heat sink with mounting holes, internal threading, and chamfered fins—all in a single CNC turning run. No additional milling or drilling was needed. This flexibility made it possible to deliver 50 units within 4 working days.

What materials and tools are required for turning heat sinks effectively?

I often get asked: “Can I use any aluminum for turning?” Not really. Not all aluminum alloys turn the same way. Plus, the tool setup makes a huge difference.

Effective turning of heat sinks requires machinable aluminum alloys like 6061 or 6063 and specialized carbide or coated inserts designed for aluminum cutting.

Suitable Materials for Turning Heat Sinks

| Aluminum Grade | Key Features | Why It Works for Turning |

|---|---|---|

| 6061-T6 | Strong, corrosion-resistant | Excellent machinability |

| 6063 | Better surface finish, softer | Preferred for aesthetic parts |

| 5052 | Good for deep drawing and forming | Used when flexibility is needed |

6061 is my go-to for most functional heat sinks because of its strength and thermal conductivity. 6063 works better when the surface finish is critical, such as for exposed parts in consumer electronics.

Recommended Tools and Equipment

- CNC Lathe3 (3-axis or higher) for complex profiles.

- Carbide Inserts4 optimized for non-ferrous metals.

- High-speed tooling to prevent chip adhesion.

- Coolant/Lubricants for temperature control and surface finish.

Also, it’s important to regularly maintain and calibrate the tooling. I keep a checklist for insert sharpness, alignment, and lubrication levels. A well-maintained lathe keeps tolerances tight and surface finishes smooth.

How does turning precision affect thermal performance of a heat sink?

In thermal management, it’s tempting to focus only on size or fin count. But even a 0.1mm surface unevenness can reduce heat transfer dramatically.

Turning precision directly affects surface contact quality, which governs how efficiently heat flows from the device to the heat sink and then into the air.

How Precision Makes a Difference

- Flatness of Mounting Base: A precise base ensures maximum contact with the heat source.

- Fin Uniformity: Even spacing optimizes airflow and thermal distribution.

- Symmetry: Helps maintain consistent airflow and cooling performance.

I once produced a batch of heat sinks with ±0.01mm tolerance and noticed a 5°C drop in chip temperature compared to standard milled units. This isn’t a minor gain. For high-performance applications, every degree matters.

Common Precision Metrics in Turning

| Feature | Standard Tolerance | High Precision Turning |

|---|---|---|

| Base Flatness | ±0.05mm | ±0.01mm |

| Diameter Roundness | ±0.1mm | ±0.02mm |

| Surface Roughness | Ra 1.6μm | Ra 0.8μm or better |

Another factor is thermal paste usage. A flat, precise heat sink reduces the need for thick thermal interface materials. That cuts thermal resistance and improves performance.

I also track repeatability across batches. A heat sink that performs well in one unit but poorly in the next is a risk. Precision machining helps keep thermal performance5 consistent, which is essential for scaled production.

Conclusion

Turning heat sinks offer unique thermal and structural benefits, especially in compact, round, or custom applications. When precision and integration matter, turning is the way to go.

-

Learn about CNC lathes and their role in creating efficient heat sinks, enhancing your knowledge of manufacturing processes. ↩

-

Learn about the importance of thermal integration in heat sinks and how it affects overall performance. ↩

-

Discover the top CNC lathes that can enhance your heat sink turning process, ensuring precision and efficiency. ↩

-

Learn how carbide inserts can significantly improve your aluminum cutting efficiency and surface finish, making your projects easier. ↩

-

Exploring this topic can provide insights into improving heat sink efficiency and overall system performance. ↩