Aluminum Extrusion Die Design CHINA: What Are Key Considerations?

What are key considerations in aluminum extrusion die design?

Every expert knows a bad die ruins the process. I have felt that frustration too. If the die warps or cracks, the profile suffers.

A proper die design ensures the final shape meets specs, runs smoothly, and lasts long.

To understand this, dive with me into the main points. We will look at geometry, flow, cooling, maintenance, and cost.

Key Aspects of Die Design

1. Geometry and Profile Complexity

The die must match the shape exactly. With complex shapes, you need internal supports. In China, I often see lightweight ribs to reduce weight and cost.

2. Metal Flow and Uniform Speed

If metal flow is uneven, the wall thickness or straightness will fail. I like to plan bridges that balance the flow rate.

3. Temperature Control

Too hot and the die warps. Too cold and it cracks. Good cooling channels help. In China, we balance simple but effective cooling.

4. Wear Resistance1

Dies must resist wear. I recommend hardened steel and surface treatments like nitriding or PVD coatings.

5. Ease of Maintenance

More parts mean more service. I always design dies that can be disassembled easily, so I can fix or recondition them fast.

6. Cost and Manufacturing Capability

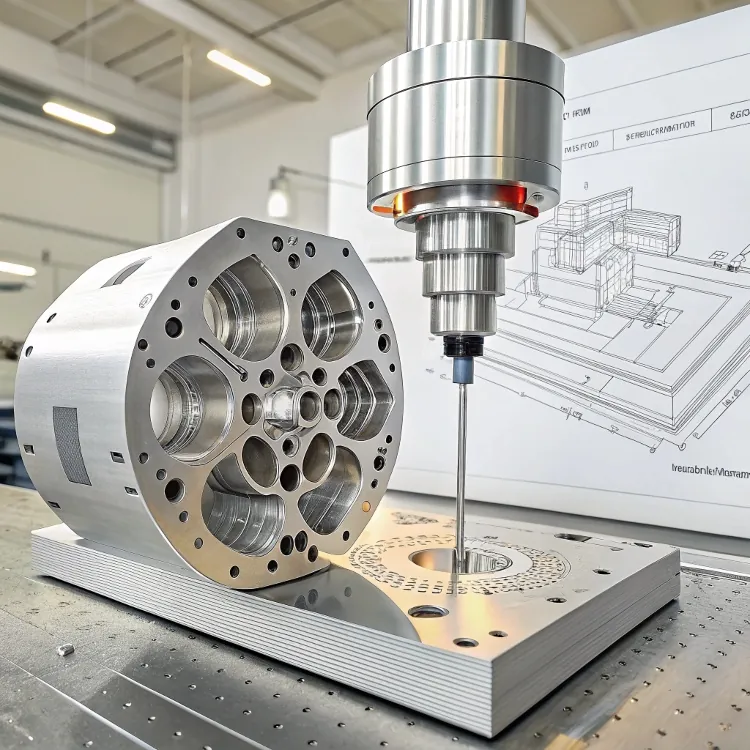

In China, cost is key. We adapt to local machine limits. Milling and EDM machines are good, so designs often avoid intricate shapes that are hard to machine.

| Consideration | Why It Matters |

|---|---|

| Geometry accuracy | Ensures profile shape and fits planned specs |

| Flow balance | Prevents defects like fish-eyes, thickness issues |

| Temperature control | Reduces die wear and avoids cracks |

| Material and coating | Extends life and cuts maintenance |

| Maintainability | Reduces downtime, improves repairability |

| Cost/manufacturing | Fits local machine limits and keeps price competitive |

Now, let’s make two true or false questions to test your knowledge:

Die geometry only matters if the profile is complex.False

Even simple profiles need accurate geometry to ensure quality.

Proper cooling channels in the die help reduce thermal stress and improve die life.True

Cooling channels help maintain uniform temperature and reduce cracking.

How to optimize die design for Chinese manufacturing?

Finding the right balance between high quality and low cost is the art here. I’ve been working with Chinese manufacturers for years. I learned there are 3 main steps:

Work with local suppliers, know their machines, adjust the design to match, and get feedback early.

Let’s explore what I do step by step.

Workflow for Chinese Die Design

1. Survey Machine Capabilities

Chinese factories commonly use 3?axis or 5?axis CNC and EDM2. Very fine features cost more. I match the die to their limits.

2. Use Standard Die Bases

I design dies that fit standard holders they already have. This reduces changeover time and cost.

3. Modular Inserts

For parts of the die that wear fast, I design inserts that can be swapped. No need to re?machine the whole die.

4. CAD/CAM Collaboration

I share CAD and CAM files and ask for feedback. I may adjust draft angles or supports to ease machining.

5. Pilot Run and Adjustment

We do a short pilot run. We measure profiles and feed that data back. We can tune the die before full production.

6. Optimize Cost and Logistics

I choose materials available locally. I also standardize sizes to avoid special charges. We partner with local heat?treat houses.

I want to show you a table to clarify this process:

| Step | What I Do |

|---|---|

| Machine survey | Learn the limits of CNC/EDM for the plant |

| Standard base design | Use holders that reduce setup time |

| Modular inserts | Swap parts that wear, preventing full die remaking |

| CAD/CAM feedback loop | Adjust in design before costly mistakes |

| Pilot testing | Make small batches to catch errors before full run |

| Local sourcing | Use cost?effective materials and local services |

Now check these statements:

I design completely new bases even if the factory already has a standard holder.False

Using existing holders saves cost and speeds setup.

Early pilot runs help identify defects and allow die tweaks before full production.True

Pilot runs provide real-world data to refine design.

What materials are best for extrusion dies?

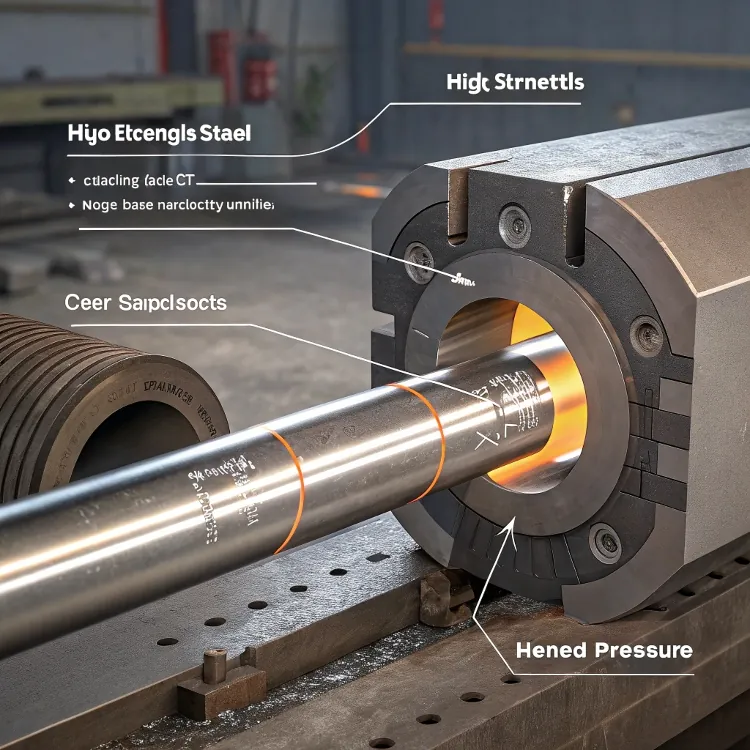

Choosing the right die material affects wear, crack resistance, and life span. Here is my usual set of choices and why I pick them:

Use high?strength steel or carbide inserts based on volume and alloy type.

Let’s look deeper.

Common Materials for Dies

A2 / D2 Tool Steel

A2 is tough and cheap. D2 holds edge longer. I like D2 for aluminium with silicon because it wears faster. These steels can be nitrided for harder surfaces.

H13 Steel

H13 can handle high heat and is often used for hot forging dies. It’s easy to machine and heat-treat, so it’s great for general use.

Powdered Metal Steels (CPM)3

CPM steels (S7, M4) have fine grains and great toughness. I use them when I expect long runs.

Carbide Inserts

For very abrasive alloys, I add carbide inserts in high wear areas. They are expensive, so I use them only as needed.

Coatings and Treatments

- Nitriding adds a hard surface and resists wear.

- PVD or CVD coatings (e.g. TiN, TiAlN) reduce friction and adhesion.

- Cryogenic treatments can boost toughness in tool steels.

Here is a summary table:

| Material / Treatment | Benefits | Use Case |

|---|---|---|

| A2 / D2 steel | Tough, wears, economic | General purpose, abrasive alloys |

| H13 steel | Heat-resistant, machinable | High-temp extrusion, easy machining |

| CPM powdered steel | Strong, tough, uniform grain | Long runs, complex dies |

| Carbide inserts | Extreme wear resistance | Abrasive alloys or long cycles |

| Nitriding or coatings | Hard surface, friction reduction | All technique levels |

Test statements:

D2 steel is always better than H13 for extrusion dies.False

H13 resists high temperature and is easier to machine, making it better for some cases.

Carbide inserts help increase die life when extruding abrasive alloys.True

They resist wear and reduce downtime in harsh conditions.

How does die design impact extrusion quality?

Die design is the heart of extrusion quality. I have seen sloppy designs ruin projects.

A well?designed die ensures accuracy, strength, and good surface finish4.

Let’s explore the main ways quality depends on design.

Quality Factors Linked to Die Design

1. Dimensional Accuracy

If the die’s geometry is off, the final profile is too. I always verify tolerances in CAD and measure pilot runs closely.

2. Wall Thickness Uniformity

Flow bridges control how the metal splits. If they are not right, you get thin or thick spots. I simulate flow or do trial runs to fine tune.

3. Surface Finish

Rough surfaces in the die cause rough aluminum. I polish critical areas and apply coatings to avoid scoring the metal.

4. Mechanical Strength

If the die has weak webs or ribs, it can crack under pressure. I add fillets and thick sections to manage stress but keep weight manageable.

5. Straightness and Bow

Uneven cooling or flow causes bow. I add symmetric flow paths and proper cooling to avoid this.

Here is a table summarizing this:

| Quality Aspect | Die Design Factor |

|---|---|

| Dimensional accuracy | Precise tooling and machining |

| Thickness uniformity | Balanced bridges and flow channels |

| Surface finish quality | High polish and low friction coatings |

| Mechanical robustness | Stress relief, fillets, proper supports |

| Straightness | Symmetry and cooling balance |

Thought questions:

Poor die design can cause surface scratches on the extruded parts.True

Rough or worn die surfaces transfer imperfections to the aluminum.

Die design does not affect the straightness of long profiles.False

Flow imbalance or thermal gradients in die design can cause bow or twist.

Conclusion

In China, careful die design means better parts, fewer stoppages, and lower cost. I combine smart geometry, local know?how, and strong materials. That gives me dies that work well and last.

-

Exploring materials and treatments for wear resistance can significantly extend the life of dies, reducing maintenance costs and downtime. ↩

-

Understanding CNC and EDM processes can enhance your die design optimization and manufacturing efficiency. ↩

-

Discover how CPM steels enhance toughness and performance in long-run applications, crucial for die longevity. ↩

-

Surface finish directly affects the aesthetic and functional properties of extruded products, making it essential for quality control. ↩