Is Aluminum a Conductor?

Aluminum is widely used in electrical applications, but how does it compare to other conductors?

Yes, aluminum is a good conductor of electricity, making it suitable for various electrical applications, especially where weight and cost are considerations.

Understanding aluminum’s conductivity, especially in comparison to copper, helps in making informed decisions for electrical installations.

How does aluminum’s conductivity compare to copper?

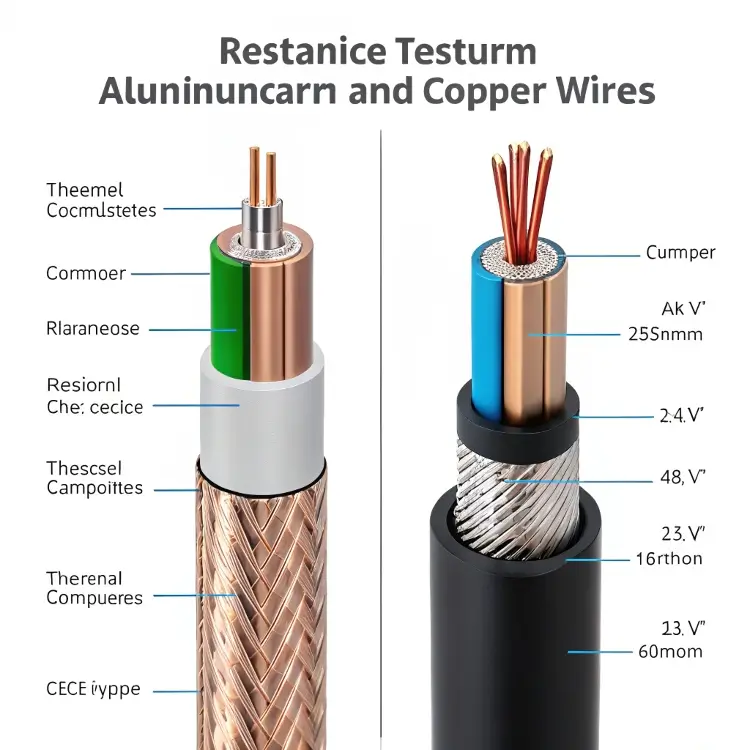

Aluminum and copper are both used as electrical conductors, but they have different properties affecting their performance.

Aluminum has about 61% of the electrical conductivity of copper but is significantly lighter and less expensive.

Comparative Table: Aluminum vs. Copper

| Property | Copper | Aluminum |

|---|---|---|

| Electrical Conductivity | 100% | ~61% |

| Density | 8.96 g/cm3 | 2.70 g/cm3 |

| Cost (per unit weight) | Higher | Lower |

| Weight (for same volume) | Heavier | Lighter |

Aluminum’s lower conductivity means that, for the same current-carrying capacity, aluminum conductors need a larger cross-sectional area than copper conductors. However, aluminum’s lighter weight1 and lower cost2 make it advantageous for overhead power lines and large-scale power distribution systems.

Aluminum has about 61% of the electrical conductivity of copper.True

This is a well-established comparison in electrical engineering, making aluminum suitable for many applications despite its lower conductivity.

Aluminum is a better electrical conductor than copper.False

Copper has higher electrical conductivity than aluminum, which is why it's often preferred for applications requiring efficient current flow.

What factors affect aluminum’s electrical conductivity?

Several factors influence how well aluminum conducts electricity, including its purity, temperature, and the presence of alloying elements.

The electrical conductivity of aluminum decreases with impurities, alloying, and temperature increases, while higher purity and proper processing can enhance it.

Key Factors Influencing Aluminum Conductivity

- Purity3: Higher purity aluminum has fewer impurities that can scatter electrons, thus increasing conductivity.

- Alloying Elements4: Adding elements like copper, magnesium, or silicon can strengthen aluminum but often at the expense of conductivity.

- Temperature3: As temperature rises, the electrical resistivity of aluminum increases, reducing its conductivity.

- Mechanical Strain: Deformation or strain can disrupt the crystal structure, affecting electron flow.

- Processing Techniques: Methods like annealing can relieve internal stresses and improve conductivity.

Understanding these factors is crucial when selecting aluminum for specific electrical applications, ensuring optimal performance.

Adding alloying elements to aluminum always increases its electrical conductivity.False

Alloying typically strengthens aluminum but usually reduces its electrical conductivity.

Higher purity aluminum has better electrical conductivity.True

Impurities in aluminum scatter electrons, so higher purity enhances conductivity.

Is aluminum suitable for electrical wiring?

Aluminum has been used in electrical wiring, especially in the mid-20th century, but its suitability depends on the application and installation practices5.

Aluminum is suitable for electrical wiring when properly installed with appropriate connectors and techniques to mitigate its limitations.

Considerations for Using Aluminum Wiring

- Expansion and Contraction: Aluminum expands and contracts more than copper, which can loosen connections over time if not properly managed.

- Oxidation: Aluminum forms an insulating oxide layer that can increase resistance at connections unless treated with antioxidant compounds.

- Compatibility: Special connectors and devices rated for aluminum wiring6 (marked AL or CO/ALR) are necessary to ensure safe connections.

- Installation Practices: Proper torque and handling during installation are critical to prevent issues like arcing or overheating.

While aluminum wiring is more common in large-scale power distribution, it can be used safely in residential and commercial buildings when these factors are carefully addressed.

Aluminum wiring is unsafe for residential use under any circumstances.False

With proper installation and materials, aluminum wiring can be safely used in residential settings.

Special connectors are required when using aluminum wiring.True

To prevent issues like oxidation and thermal expansion, connectors rated for aluminum are necessary.

What are the pros and cons of using aluminum conductors?

Choosing aluminum conductors involves weighing their advantages against potential drawbacks.

Aluminum conductors offer benefits like lower cost and weight but require careful installation to address issues like oxidation and thermal expansion.

Advantages

- Cost-Effective7: Aluminum is generally less expensive than copper, making it attractive for large-scale projects.

- Lightweight: Its lower density reduces the overall weight of wiring systems, beneficial in applications like aerospace and overhead power lines.

- Corrosion Resistance8: Aluminum naturally forms a protective oxide layer, enhancing its durability in certain environments.

Disadvantages

- Lower Conductivity: Requires larger cross-sectional areas to match the current-carrying capacity of copper.

- Thermal Expansion9: Greater expansion and contraction can lead to loose connections if not properly managed.

- Oxidation: The oxide layer, while protective, is non-conductive and can increase resistance at connections without proper treatment.

- Mechanical Strength: Aluminum is more prone to deformation and breakage under stress compared to copper.

Proper design and installation practices can mitigate many of these disadvantages, making aluminum a viable option in various electrical applications.

Aluminum conductors are always inferior to copper conductors in all aspects.False

While copper has higher conductivity, aluminum offers advantages like lower cost and weight, making it suitable for many applications.

Aluminum conductors require larger cross-sectional areas than copper conductors to carry the same current.True

Due to its lower conductivity, aluminum must be thicker to match copper's current-carrying capacity.

Conclusion

Aluminum is a viable electrical conductor with specific advantages and considerations. Its lower cost and weight make it suitable for many applications, provided that its limitations are addressed through proper material selection and installation practices.

-

Discovering the advantages of aluminum’s lighter weight can enhance your knowledge of its applications in power distribution. ↩

-

Exploring the cost benefits of aluminum can provide insights into its use in various industries and applications. ↩

-

Understanding this relationship is vital for applications where temperature variations occur, ensuring reliable performance of aluminum conductors. ↩ ↩

-

This resource will help you understand the trade-offs between strength and conductivity when alloying aluminum, crucial for material selection. ↩

-

Discover essential installation practices to ensure the safety and efficiency of aluminum wiring. ↩

-

Explore this link to understand the safety and best practices for using aluminum wiring in homes. ↩

-

Explore how cost-effective aluminum conductors can save money in large-scale projects while maintaining efficiency. ↩

-

Learn about the natural protective oxide layer of aluminum and its impact on durability in various environments. ↩

-

Understand the implications of thermal expansion in aluminum conductors and how to manage them effectively. ↩