Extruded Aluminum For LED Heat Sink?

LEDs run cool, right? Not always. Without proper heat sinks, even the most efficient LEDs can fail early. That’s where extruded aluminum steps in.

Extruded aluminum heat sinks offer excellent thermal conductivity, lightweight structure, and design flexibility, making them ideal for managing LED heat dissipation.

Thermal performance affects everything—from brightness and lifespan to safety and cost. Let’s dive into how aluminum extrusion transforms LED heat sink design.

What are the benefits of using extruded aluminum for LED heat sinks?

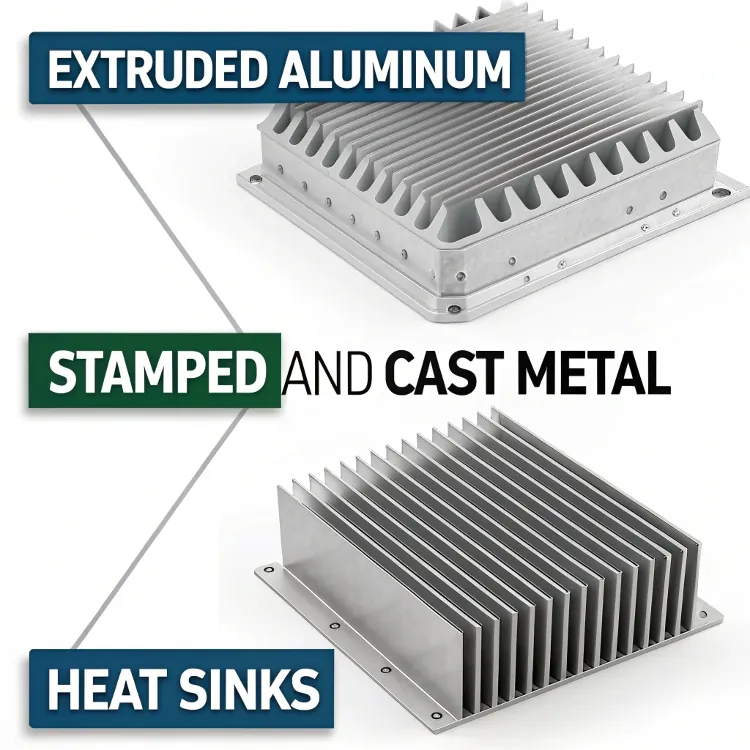

Clients often ask me why we don’t just use stamped or cast metal. The answer lies in performance and customization.

Extruded aluminum heat sinks1 provide superior thermal conductivity, structural strength, and design flexibility, all while keeping costs and weight low.

Main Benefits Explained

| Benefit | Description |

|---|---|

| High Thermal Conductivity2 | Aluminum efficiently transfers heat from LED to environment |

| Lightweight | Easy to install and support on delicate fixtures |

| Customizable Shapes3 | Extrusion allows complex, optimized fin designs |

| Corrosion Resistance | Naturally resists oxidation, especially when anodized |

| Cost-Effective | Lower production cost at scale compared to CNC or casting |

Extrusion lets us make linear shapes with thin, spaced fins—ideal for airflow and heat transfer. This makes them perfect for everything from streetlights to industrial LED panels.

Extruded aluminum is too heavy for use in LED applications.False

Aluminum is lightweight and ideal for LED heat sinks, balancing weight and strength.

Extruded aluminum allows complex shapes that improve heat dissipation.True

Yes, the extrusion process enables intricate fin designs for better airflow and cooling.

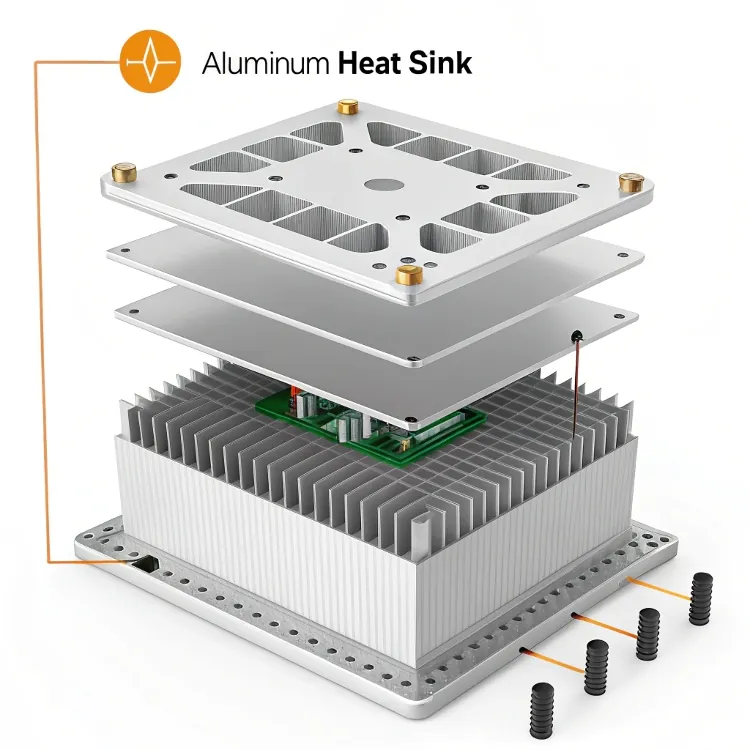

How does aluminum extrusion4 enhance LED thermal management5?

If an LED overheats, it dims, fails, or worse—catches fire. Thermal management isn’t optional.

Aluminum extrusion improves LED thermal management by increasing surface area and enabling airflow through optimized fin geometry.

Why Extrusion Works So Well

- Surface Area: More area = more heat dissipation.

- Airflow Channels: Proper fin spacing lets air pass through naturally.

- Custom Geometry: Extrusion creates detailed shapes like pin-fin or straight-fin profiles.

Design Tip

Use vertical fins in natural convection settings (e.g., hanging lights) and radial or pin designs for enclosed or forced-air systems. Here’s a comparison:

| Fin Design | Airflow Type | Application Example |

|---|---|---|

| Straight Fins | Natural convection | Indoor panel lights |

| Pin Fins | Forced convection | LED spotlights with fans |

| Flared Fins | Open air designs | Outdoor floodlights |

When heat is managed well, LED lifespan increases dramatically. That’s why extrusion is the industry’s go-to.

Aluminum extrusion limits airflow in heat sink design.False

It actually enhances airflow through customizable fin spacing and geometry.

Thermal management is critical to LED performance.True

LED brightness, longevity, and safety all depend on efficient heat dissipation.

What factors influence the efficiency of aluminum heat sinks?

It’s not just about the metal. Several design and environmental variables affect how well a heat sink performs.

The efficiency of aluminum heat sinks is influenced by fin design6, surface area, airflow, mounting position, and surface treatment7.

Key Efficiency Factors

| Factor | Impact |

|---|---|

| Fin Thickness & Spacing | Affects airflow and thermal surface area |

| Airflow Direction | Natural or forced airflow8 changes cooling rate |

| Surface Treatment | Anodizing or painting can influence radiation and durability |

| Mounting Orientation | Horizontal vs. vertical affects convection |

| Contact Resistance | Quality of contact between LED and heat sink matters |

Pro Tip

Always pair the right thermal paste or pad between the LED and heat sink. Poor contact kills heat transfer and reduces lifespan.

Heat sink efficiency isn’t just about material—it’s about how everything fits and flows together. Test different setups to find what works best for your application.

Surface treatments like anodizing don’t affect heat sink performance.False

Anodizing can improve emissivity and corrosion resistance, both of which impact performance.

The position of the heat sink influences its thermal efficiency.True

Yes, vertical mounting allows better convection, improving heat dissipation.

How does anodizing affect aluminum heat sink performance?

I’ve had clients skeptical about anodizing. They think it’s just cosmetic. But it goes deeper—literally.

Anodizing enhances aluminum heat sink performance by increasing emissivity9, improving corrosion resistance10, and maintaining surface integrity over time.

Benefits of Anodized Heat Sinks

| Property | Anodized vs. Bare Aluminum |

|---|---|

| Emissivity | Higher (better thermal radiation) |

| Corrosion Resistance | Significantly improved |

| Electrical Insulation | Optional depending on process |

| Surface Hardness | Increases durability |

The color doesn’t matter much. What matters is the oxide layer that improves heat radiation—especially useful when airflow is limited. Hard anodizing also protects the fins from scratches or bending during installation.

Anodized heat sinks also stay cleaner longer, which helps maintain consistent thermal performance.

Anodized aluminum has higher thermal emissivity than raw aluminum.True

The anodized oxide layer improves radiation of heat, especially in low airflow conditions.

Anodizing reduces the durability of aluminum heat sinks.False

Anodizing increases surface hardness, protecting the heat sink from wear and corrosion.

Conclusion

Extruded aluminum heat sinks are the backbone of reliable LED design. They’re light, strong, and efficient—and when anodized, they last even longer. Choose the right shape, position, and surface finish, and your LEDs will stay cool and last for years.

-

Explore the benefits of extruded aluminum heat sinks, including thermal conductivity and design flexibility, to enhance your LED projects. ↩

-

Understanding high thermal conductivity can help you choose the right materials for effective heat management in LED systems. ↩

-

Learn how customizable shapes can optimize heat dissipation and enhance the efficiency of your LED lighting solutions. ↩

-

Explore how aluminum extrusion enhances LED performance and longevity through effective thermal management. ↩

-

Learn about essential thermal management techniques to ensure LED efficiency and safety. ↩

-

Understanding fin design can significantly enhance heat sink performance, making it crucial for effective cooling solutions. ↩

-

Surface treatment can improve durability and thermal performance, making it essential for optimizing heat sink efficiency. ↩

-

Airflow is a key factor in heat dissipation; exploring this can lead to better cooling strategies for your projects. ↩

-

Learn how increasing emissivity can significantly improve thermal radiation in heat sinks, enhancing their effectiveness. ↩

-

Discover the importance of corrosion resistance in heat sinks and how anodizing plays a crucial role in extending their lifespan. ↩