What is 7075 Aluminum Extrusion?

7075 aluminum sounds like a superhero metal—and in some ways, it is. But is it right for extrusion? And why do engineers love it so much? Let’s unpack its secrets.

7075 aluminum extrusion is a high-strength, precision-formed aluminum product made by forcing 7075 alloy through a die, widely used in aerospace, motorsports, and high-performance industries.

This grade is strong, light, and tough. But not every project needs that power. Let’s explore when and how to use 7075 in extrusion.

Can 7075 aluminum be extruded?

You might think that the strongest metals are the hardest to shape—and you’d be right.

Yes, 7075 aluminum can be extruded, but it requires special care due to its high strength and lower formability compared to other aluminum grades.

Challenges of Extruding 7075

7075 contains zinc as its primary alloying element, which gives it high strength1—but also makes it more brittle than 6xxx or 5xxx series.

| Property | 6061 | 7075 |

|---|---|---|

| Extrudability | Excellent | Moderate to Difficult |

| Strength | High | Very High |

| Ductility | Good | Lower |

| Common Use in Extrusions | General purpose | Aerospace, military |

Why Still Use It?

Despite the difficulty, extruding 7075 is worth it when strength matters most. Aircraft frames, high-load brackets, and racing parts are common examples.

7075 aluminum cannot be extruded due to its strength.False

7075 can be extruded, though it requires careful control during the process.

7075 aluminum is extruded for high-performance structural applications.True

Yes, it’s used where high strength is critical, like aerospace and automotive.

What does 7075 mean in aluminum?

This isn’t just a random number. It tells you what’s inside the alloy—and what it can do.

7075 in aluminum refers to an alloy series where zinc is the primary element, known for its extremely high strength and moderate corrosion resistance.

Understanding the Numbering

- 7xxx series: Zinc-based

- 0: Indicates the first modification of the original alloy

- 75: Identifies the specific alloy in the series

Key Properties of 7075

| Property | Value |

|---|---|

| Main Alloying Element | Zinc (5.6–6.1%) |

| Strength (T6) | 74,000–83,000 psi |

| Corrosion Resistance | Moderate |

| Machinability | Excellent |

| Weldability | Poor |

This alloy is often heat-treated to the T6 or T73 temper2, which dramatically boosts strength while balancing stress resistance.

7075 aluminum has excellent corrosion resistance.False

7075 is strong but has only moderate corrosion resistance compared to 5xxx series.

The number 7075 identifies an aluminum alloy primarily alloyed with zinc.True

Correct—7075 belongs to the 7xxx series, where zinc is the main alloying element.

Can you anodize 7075 aluminum?

I get this question a lot—especially from clients in electronics or precision gear sectors who want that anodized look.

Yes, 7075 aluminum can be anodized, but it may not take dye as evenly as other grades and needs special care to avoid surface pitting.

Anodizing 7075: Pros and Cons

| Factor | Result |

|---|---|

| Appearance | Slightly uneven dye uptake |

| Surface Finish | Acceptable but not ideal |

| Protective Layer | Durable, less uniform |

| Ideal Applications | Non-cosmetic parts |

Tips for Better Results

- Use hard anodizing3 for technical applications.

- Avoid decorative finishes unless you pre-test.

- Seal the anodized layer4 well to prevent corrosion in harsh environments.

7075 is anodized primarily for protection, not for beauty. If color and finish matter most, consider 6061 instead.

7075 aluminum is ideal for decorative anodizing.False

Its uneven dye absorption makes it less suitable for decorative finishes.

7075 can be anodized to improve corrosion resistance.True

While not ideal for looks, anodizing does add a protective layer to 7075.

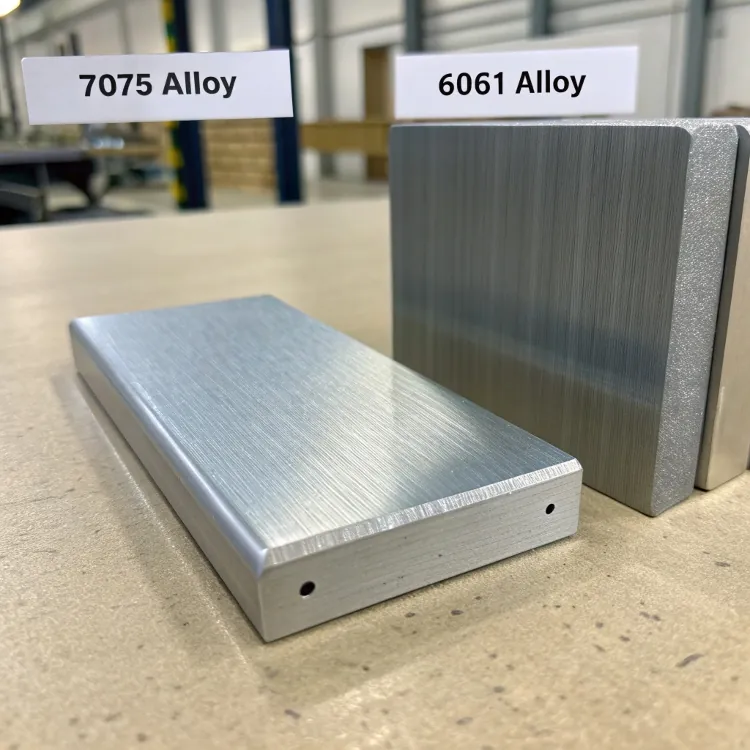

What grade of aluminium is used for extrusion?

When it comes to extrusion, not all aluminum grades are equal. Some bend easily. Others snap under pressure.

The most commonly used aluminum grades for extrusion are 6061 and 6063, thanks to their excellent extrudability, strength, and surface finish.

Top Aluminum Grades for Extrusion

| Grade | Why It’s Used |

|---|---|

| 6063 | Best for complex shapes and aesthetics |

| 6061 | Strong, versatile, widely available |

| 6005 | Great for structural shapes |

| 7075 | Used for high-performance parts |

| 2024 | Occasionally used for strength |

Choosing the Right Grade

- Go with 60635 if appearance matters—think window frames or decorative trims.

- Use 6061 for general engineering and industrial strength needs.

- Select 70756 when strength is more important than cost or formability.

In my projects, I usually recommend 60617 or 6063 unless the client specifically needs the added strength of 7075. These alloys strike the right balance between ease of manufacture and performance.

6063 is one of the most extrudable aluminum alloys.True

6063 is often used for complex shapes due to its excellent extrudability and surface finish.

2024 is the most common extrusion alloy.False

6061 and 6063 are far more commonly used for extrusion than 2024.

Conclusion

7075 aluminum is strong, light, and high-performing—but it’s not for every job. It can be extruded and anodized, but with some limitations. For most extrusions, 6061 and 6063 are still the go-to grades. Choose the one that fits your needs—not just the one with the highest specs.

-

Discover the advantages of high strength aluminum alloys and how they can be utilized in various industries for enhanced performance. ↩

-

Discover how heat treatment enhances the performance of aluminum alloys like T6 and T73, making them suitable for demanding applications. ↩

-

Learn about hard anodizing to see how it enhances durability and performance in technical applications. ↩

-

Discover effective sealing methods for anodized layers to ensure long-lasting protection against corrosion. ↩

-

Discover why 6063 aluminum is the go-to choice for aesthetics and intricate designs in extrusion. ↩

-

Learn about the exceptional strength of 7075 aluminum, perfect for demanding applications. ↩

-

Explore the versatility and strength of 6061 aluminum, ideal for various engineering applications. ↩