What are the different types of trailers that can use aluminum extrusions?

Many trailer buyers worry about weight, corrosion, and long-term costs. Steel trailers rust. Heavy frames reduce fuel efficiency. What’s the smarter solution?

Aluminum extrusions are ideal for trailer manufacturing because they reduce weight, resist corrosion, and offer excellent strength-to-weight ratio, making trailers more durable and fuel-efficient.

If you’ve ever dealt with trailer repairs or high fuel bills, this article will help. We’ll explore why aluminum extrusions are gaining popularity across different trailer types.

Why is aluminum ideal for trailer manufacturing?

Many people are stuck with steel trailers that corrode quickly and weigh too much. These old-school choices lead to maintenance issues and lost money over time.

Aluminum is perfect for trailer manufacturing because it is light, corrosion-resistant, strong, and easy to fabricate into complex shapes.

Aluminum helps solve four major trailer challenges: weight, corrosion, durability, and customization. It’s up to 60% lighter than steel. That means better fuel economy. Less wear on tires and axles. And easier towing. It also doesn’t rust. Even in harsh weather.

Another big plus is aluminum’s formability1. With aluminum extrusions, we can create parts with tight tolerances. This helps us reduce waste and improve assembly speed.

Key Properties of Aluminum in Trailer Design

| Property | Benefit in Trailer Manufacturing |

|---|---|

| Lightweight | Improved fuel efficiency and handling |

| Corrosion Resistance | Longer lifespan, reduced maintenance |

| Strength | Structural integrity under load |

| Formability | Flexible designs and reduced waste |

| Recyclability | Lower environmental footprint |

Aluminum trailers are more resistant to corrosion than steel trailers.True

Aluminum naturally forms an oxide layer that protects it from rust and environmental damage.

Aluminum trailers are heavier and less durable than steel ones.False

Aluminum is lighter than steel and offers a strong strength-to-weight ratio, making it ideal for trailers.

Which trailer types benefit most from aluminum extrusions?

Some buyers think only luxury or lightweight trailers use aluminum. That’s wrong. Many heavy-duty trailers now switch to aluminum to cut operating costs.

Flatbeds, utility trailers, livestock haulers, and enclosed cargo trailers all benefit greatly from using aluminum extrusions.

Flatbed trailers use long, straight aluminum extrusions2 for frames and crossmembers. These reduce the trailer’s weight and make it easier to haul large loads. Utility trailers—often used by landscapers—need corrosion resistance because they’re always outdoors. Aluminum extrusions offer just that.

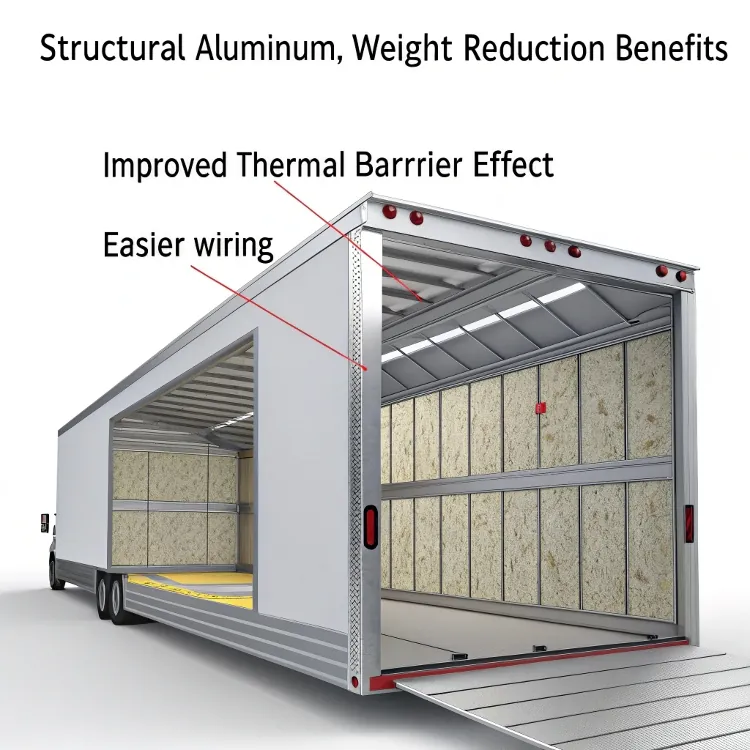

Enclosed trailers use aluminum for roof bows, wall studs, and floor panels. This allows for better thermal performance, lighter doors, and easy access to wiring and insulation.

Common Trailer Types Using Aluminum Extrusions

| Trailer Type | Aluminum Parts Used |

|---|---|

| Flatbed Trailers | Beams, decking supports, rub rails |

| Utility Trailers | Side rails, frames, tongue members |

| Livestock Trailers | Interior gates, floor sections, side panels |

| Enclosed Cargo | Roof bows, wall frames, door frames |

Aluminum extrusions also allow easy mounting of accessories like tie-downs, toolboxes, and ramps. This flexibility saves production time and lets us tailor each trailer to a customer’s needs.

Enclosed cargo trailers use aluminum extrusions for both structural and aesthetic purposes.True

Aluminum parts help form the trailer’s internal structure and allow for clean, smooth exterior finishes.

Aluminum is rarely used in utility trailers due to its high cost.False

Despite the upfront cost, aluminum’s low maintenance and longer life make it a cost-effective material for utility trailers.

How do aluminum extrusions improve trailer durability?

Some people assume aluminum is too soft for trailers. But that’s a myth. The truth is, aluminum alloys used in extrusion are strong enough for commercial use.

Aluminum extrusions improve durability by offering consistent strength, corrosion resistance, and the ability to absorb stress without cracking.

Aluminum trailers don’t crack under stress as easily as some believe. Instead, extruded profiles are engineered to distribute loads more evenly. This means less fatigue over time. Especially in trailers that face rough terrain or frequent loading.

Welded aluminum joints also perform well. They resist fatigue cracking and stand up to years of use. For even better performance, some manufacturers use bolt-together extrusion systems that allow easier repairs and upgrades.

How Aluminum Adds to Trailer Durability

- Corrosion Resistance: No rust means longer life

- Fatigue Resistance: Extrusions reduce stress concentration

- Thermal Stability: Aluminum handles temperature swings well

- Maintenance Needs: Fewer repairs due to weather resistance

This durability directly affects a trailer’s resale value. Buyers will pay more for trailers that look and perform like new, even after years of service.

Aluminum extrusions crack easily and reduce trailer lifespan.False

Properly engineered aluminum extrusions offer strong load distribution and long-term durability.

Aluminum extrusions help distribute stress, reducing fatigue and improving trailer longevity.True

Extruded aluminum shapes are designed to evenly carry loads, preventing weak points and cracks.

Are aluminum trailers more fuel-efficient than steel ones?

Fuel cost is a major concern for trailer owners. Many assume there’s no real difference between aluminum and steel. But that’s not true.

Yes, aluminum trailers are more fuel-efficient than steel ones due to their significantly lower weight.

A lighter trailer means the towing vehicle uses less fuel. For commercial fleets, this can lead to huge savings over time. For individual owners, it means fewer trips to the gas station and lower emissions.

Consider this: a steel flatbed trailer might weigh 7,000 pounds. An aluminum version could weigh just 4,500. That’s a 36% weight reduction3. The less weight you pull, the less power you need. Which translates into better fuel mileage.

Fuel Savings with Aluminum Trailers

| Trailer Type | Steel Weight (lbs) | Aluminum Weight (lbs) | Estimated Fuel Savings |

|---|---|---|---|

| Flatbed Trailer | 7,000 | 4,500 | 10–15% |

| Utility Trailer | 2,000 | 1,200 | 5–10% |

| Enclosed Cargo | 4,000 | 2,800 | 8–12% |

Lighter trailers also reduce wear on brakes, tires, and suspension. This means less maintenance and more uptime for your fleet or business.

Aluminum trailers help reduce overall towing weight and increase fuel efficiency.True

Lighter trailers require less energy to tow, which improves fuel mileage.

Aluminum trailers weigh more than steel trailers and consume more fuel.False

Aluminum is significantly lighter than steel, which reduces the load and saves fuel.

Conclusion

Aluminum extrusions make trailers lighter, stronger, and more fuel-efficient. From flatbeds to enclosed cargo haulers, this material changes how we build and use trailers for the better.

-

Discover how aluminum’s formability allows for innovative designs and efficient manufacturing processes in trailer production. ↩

-

Explore how aluminum extrusions enhance trailer performance, durability, and customization options, making them a smart choice for various trailer types. ↩

-

Explore the relationship between trailer weight and fuel efficiency to make informed towing decisions. ↩