What is a pin fin heat sink?

Many electronic devices overheat and fail because of poor thermal design. If your project is sensitive to temperature, you need to choose the right heat sink early.

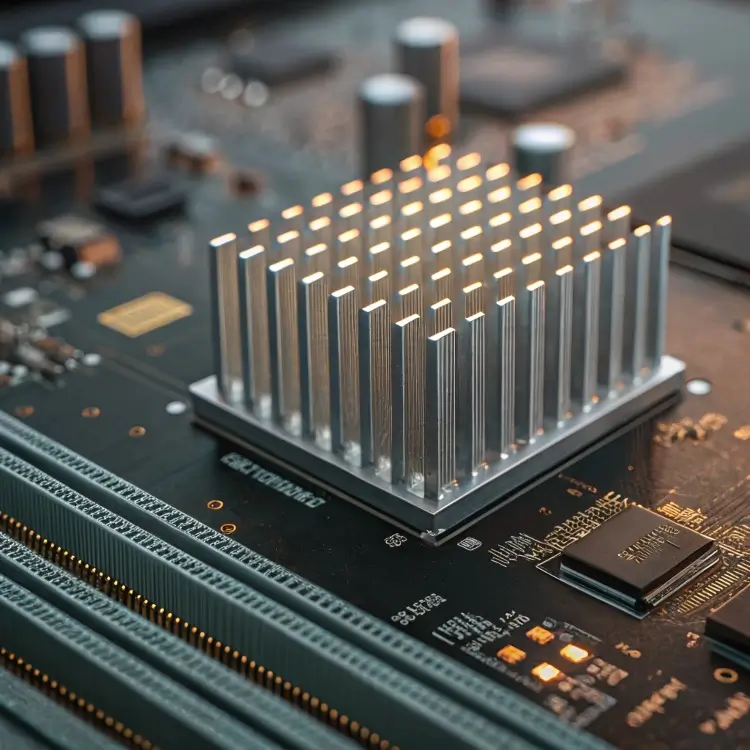

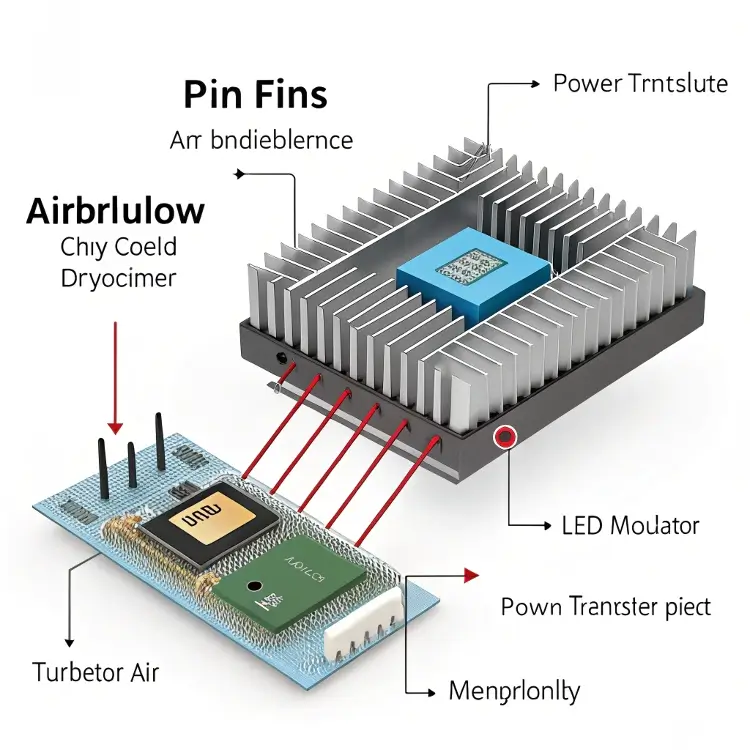

A pin fin heat sink is a cooling component that uses vertical pins to dissipate heat through increased surface area and airflow. It is often used for dense layouts and omnidirectional airflow.

If you’re designing products for industrial automation, LEDs, or compact electronics, using the right type of heat sink can reduce failure rates and improve efficiency. In this article, I’ll break down what a pin fin heat sink is, how it compares to other types, and how to choose the right one.

What is a pin fin in heat transfer?

Many people misunderstand how fins work in thermal systems. It’s not just about metal shapes—it’s about controlling airflow and maximizing contact area.

A pin fin in heat transfer is a small cylindrical or square post that increases the surface area of a component to dissipate heat more efficiently through convection.

Pin fins are used to cool components that generate heat, such as chips, power transistors, or LED modules. These pins break up airflow, causing turbulence. Turbulence increases heat transfer by mixing layers of air more effectively.

Key Functions of Pin Fins

| Function | Description |

|---|---|

| Increase Surface Area | More area means more heat can move from the metal to the surrounding air. |

| Promote Turbulence | Creates airflow disruption to enhance convection. |

| Enable Omnidirectional Cooling | Works well even if air is not moving in a straight line. |

Why Use Pin Fins in CNC-Machined Parts?

When we design aluminum housings or frames, sometimes our clients require specific thermal properties. If the heat needs to dissipate equally in all directions, I often recommend pin fin1 structures. They’re especially useful when the product has unpredictable airflow, like in hand-held or enclosed devices.

What is a fin heat sink?

Many new buyers ask me, “Is a fin heat sink the same as a pin fin?” The answer is: not quite. The word “fin” is general, while “pin fin2” is one kind of fin.

A fin heat sink is a device that uses extended surfaces (called fins) to transfer heat away from a heat-generating component into the surrounding air.

The basic idea behind any fin structure is surface area. The more surface you have, the more contact with air. That means better cooling.

Types of Fins in Heat Sinks

| Fin Type | Description | Application |

|---|---|---|

| Straight Fin | Thin vertical walls, often in rows | Directional airflow, like fans |

| Pin Fin | Short posts, square or round | Omnidirectional cooling, compact space |

| Flared Fin | Wider apart at the ends | Natural convection |

| Louvered Fin | Tiny slots or folds in each fin | High-performance systems |

In my experience with medical device clients, I often use thin straight fins when the device has forced airflow (like a built-in fan). But when the cooling depends on natural convection, pin fins or flared fins are much more effective.

What is the difference between pin fin and plate fin heat sinks?

A lot of engineers we work with want to balance cost, airflow design3, and footprint. But when choosing between pin and plate fin heat sinks, you need to consider your airflow environment.

Pin fin heat sinks use vertical pins for omnidirectional cooling, while plate fin heat sinks use flat plates for directional airflow and are more efficient under forced convection.

Head-to-Head Comparison

| Feature | Pin Fin Heat Sink | Plate Fin Heat Sink |

|---|---|---|

| Airflow Direction | Omnidirectional | Linear/Directional |

| Surface Area | High (multi-directional fins) | High (depending on density) |

| Ideal for | Natural convection or random air | Forced airflow (fans) |

| Manufacturing Process | More complex (CNC or casting) | Easier (extrusion, CNC) |

| Cost | Usually higher | Generally lower |

When Do I Recommend Each Type?

When a client designs a compact device without space for a fan—like a wearable or small camera—I suggest pin fins. But if they use active cooling (like a fan in an industrial controller), I usually go for plate fins.

What are the types of heat sinks?

Sometimes buyers think all heat sinks are the same, but there are many kinds. Choosing the wrong type can cause overheating or wasted budget.

The main types of heat sinks include pin fin, plate fin, folded fin, bonded fin, skived fin4, and heat pipe-assisted sinks. Each type suits a specific airflow and space condition.

Common Types of Heat Sinks

| Type | Description | Common Use Case |

|---|---|---|

| Pin Fin | Small pins in a block shape | Natural convection, tight spaces |

| Plate Fin | Vertical flat plates | Forced airflow systems |

| Skived Fin | Fins carved directly from a solid block | High-performance, compact devices |

| Folded Fin | Thin metal sheets folded into fin shapes | Lightweight, low-cost applications |

| Bonded Fin | Fins glued or brazed onto the base | Larger units, customized designs |

| Heat Pipe | Tubes with working fluid to transfer heat efficiently | High heat transfer, uneven heat loads |

How I Help Clients Choose the Right Type

I usually start by asking about the following:

- Airflow condition: Is there a fan or is it natural convection?

- Size limits: How much space do we have for fins?

- Power output: How much heat needs to be removed?

- Orientation: Is the heat sink vertical or horizontal?

Based on these, I recommend the structure that balances performance and cost. For instance, a wearable health sensor might use a small skived fin. An industrial power amplifier may use a bonded fin heat sink with a heat pipe.

Conclusion

Choosing the right heat sink design—especially pin vs. plate fin—depends on airflow, application, and thermal demands. Getting it right can save you rework and overheating issues.

-

Explore this link to understand the mechanics and benefits of pin fins in enhancing heat transfer efficiency. ↩

-

Learn about pin fin heat sinks and their unique advantages in compact cooling solutions. ↩

-

Learn how airflow design influences heat sink performance, crucial for selecting the right type for your project. ↩

-

Learn about skived fin heat sinks and why they are preferred for high-performance, compact devices. ↩