Aluminum extrusion cross-section complexity limits?

Many extrusion projects fail quietly. The drawing looks perfect, but production struggles. Costs rise. Lead time grows. The real problem is often hidden in cross-section complexity.

Aluminum extrusion cross-section complexity has clear limits, and those limits are set by metal flow, tooling strength, and process control rather than imagination.

Complex sections are possible, but only when design respects how aluminum actually moves under pressure. This article explains where the limits are and how to design within them.

How complex can extrusion cross-sections become?

Designers often push complexity to reduce assembly steps. This goal is valid, but it creates risk if limits are ignored.

Aluminum extrusion cross-sections can be highly complex, including multiple cavities, thin walls, and asymmetric shapes, but complexity is limited by uniform metal flow and die strength.

Complexity itself is not the enemy. Imbalance is.

What defines complexity in extrusion

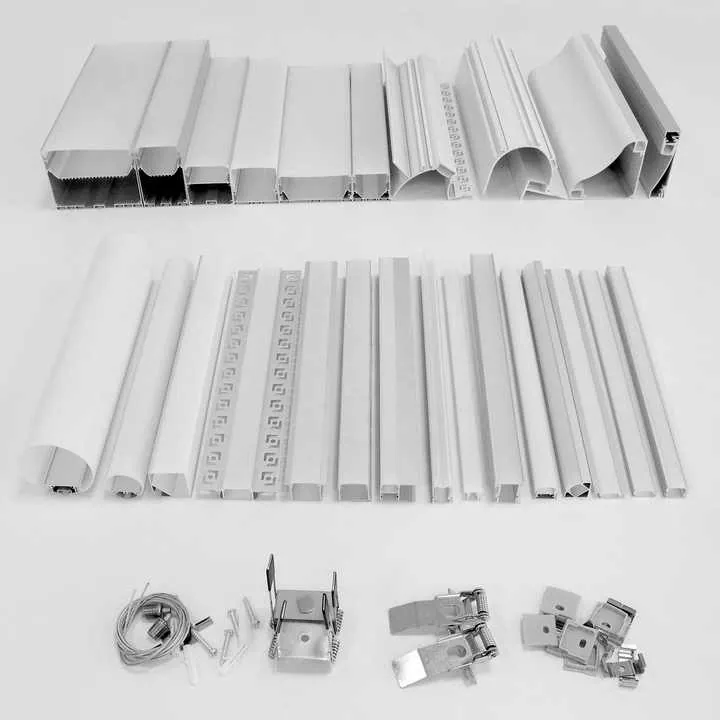

Complexity is not only about shape. It includes several factors:

- Number of hollow chambers

- Wall thickness variation

- Fine grooves or teeth

- Asymmetry across the section

- Long unsupported die features

A section with many features is harder to control than a simple box.

Solid, semi-hollow, and hollow sections

Extrusion sections fall into three main groups.

- Solid sections have no enclosed voids

- Semi-hollow sections have deep slots or narrow gaps

- Hollow sections have fully enclosed cavities

Each step increases tooling difficulty.

| Section type | Typical complexity level | Tooling difficulty |

|---|---|---|

| Solid | Low to medium | Low |

| Semi-hollow | Medium to high | Medium |

| Hollow | High to very high | High |

Hollow sections need bridge or porthole dies, which add flow challenges.

Why symmetry matters

Symmetrical sections allow aluminum to flow evenly. Asymmetry causes uneven speed and pressure.

Uneven flow leads to:

- Twisting

- Dimensional drift

- Surface defects

Highly asymmetric sections often need extra design compensation.

Real design boundary

In practice, a section becomes too complex when it cannot extrude at a stable speed without defects.

If speed must drop too low, productivity collapses. At that point, redesign is cheaper than forcing production.

Aluminum extrusion cross-sections can be very complex if metal flow remains balanced.True

Balanced flow allows complex shapes to form without distortion.

There is no practical limit to extrusion cross-section complexity if the press is large enough.False

Tooling strength and flow balance limit complexity regardless of press size.

What design features push tooling to its limits?

Many extrusion problems are not caused by the press. They come from the die.

Certain design features push extrusion tooling to its mechanical and thermal limits, increasing failure risk and reducing die life.

Knowing these features helps designers avoid hidden traps.

Extremely thin walls

Thin walls look efficient. They save weight and material.

But thin walls increase resistance to flow. Aluminum cools fast and may freeze before filling the die.

Walls below a certain thickness often cause:

- Incomplete filling

- Tearing

- High scrap rates

Sharp internal corners

Sharp corners concentrate stress in the die.

They also disrupt metal flow and increase friction.

Rounded corners improve:

- Die life

- Surface quality

- Dimensional stability

Long unsupported die tongues

In hollow and semi-hollow dies, tongues support internal voids.

Long or thin tongues bend under pressure.

This leads to:

- Dimensional drift

- Die breakage

- Sudden production stops

Large thickness variation

Sections with both very thick and very thin areas are hard to balance.

Metal flows faster through thick zones and slower through thin zones.

This imbalance causes twisting and wave defects.

| Risk feature | Main problem caused |

|---|---|

| Thin walls | Incomplete fill |

| Sharp corners | Die cracking |

| Long tongues | Tool deformation |

| Thickness jumps | Flow imbalance |

High cavity count

Multiple cavities in one section increase complexity.

Each cavity must receive equal metal flow.

As cavity count rises, control becomes harder.

Production reality insight

In one project, a profile had six internal cavities with thin walls. The die failed twice before redesign.

After reducing cavity count to four and thickening walls slightly, production stabilized.

Thin walls and sharp corners significantly increase tooling stress.True

They raise flow resistance and concentrate stress in the die.

Tooling limits are mainly determined by die steel quality, not section design.False

Section geometry plays a major role in tooling limits.

Can very fine details be maintained during extrusion?

Fine details are attractive. Logos, micro-grooves, and small teeth are common requests.

Very fine details can be extruded, but maintaining them consistently depends on size, depth, and process stability.

Not all details survive real production.

What counts as fine detail

Fine details include:

- Narrow grooves

- Small ribs

- Fine teeth

- Shallow text or symbols

These features are often below a few tenths of a millimeter.

Limits of metal flow resolution

Aluminum under pressure behaves like thick fluid.

If a feature is too small, metal cannot fully enter before cooling.

This leads to rounded or incomplete details.

Die wear over time

Even if fine details form at first, they may not last.

As the die wears:

- Sharp edges round off

- Groove depth reduces

- Detail clarity fades

This causes variation between early and late production batches.

Surface finish impact

Fine details are sensitive to surface defects.

Minor scratches or pickup can destroy small features visually.

Practical tolerance reality

Designers often specify tight tolerances on fine features.

In practice, tolerances must allow some variation.

| Feature size | Typical consistency |

|---|---|

| >1.0 mm | Stable |

| 0.5 to 1.0 mm | Moderate |

| <0.5 mm | Difficult |

Below certain sizes, secondary machining may be more reliable.

Design strategy that works

Instead of forcing micro-details into extrusion, many projects:

- Extrude a simpler shape

- Add CNC machining for fine features

This balances cost and reliability.

Real production lesson

A customer requested a fine internal groove for sealing. The groove filled unevenly.

After redesigning the groove as a wider channel and adding a gasket, performance improved.

Very fine extrusion details are sensitive to flow and die wear.True

Small features are harder to fill and maintain consistently.

Once a fine detail can be extruded once, it will remain consistent for all production.False

Die wear and process variation reduce detail consistency over time.

Are there software tools to test section feasibility?

Many problems can be avoided before steel is cut. Software plays a key role here.

Simulation and design software can evaluate extrusion section feasibility by predicting metal flow, stress, and temperature.

These tools do not replace experience, but they reduce risk.

Types of software used in extrusion design

There are two main categories:

- CAD tools for geometry

- Simulation tools for process behavior

CAD alone cannot predict extrusion success.

What simulation tools can analyze

Simulation software can show:

- Metal flow speed

- Pressure distribution

- Temperature changes

- Die stress zones

These insights highlight risk areas early.

Benefits of early simulation

Using software before die making helps to:

- Adjust wall thickness

- Balance flow paths

- Reduce trial runs

- Extend die life

This saves both time and cost.

Limits of software predictions

Simulation is not perfect.

Results depend on:

- Material data accuracy

- Boundary conditions

- Operator experience

Software supports decisions, but final judgment still matters.

Typical workflow using software

- Initial section design

- Flow simulation

- Geometry adjustment

- Die design optimization

- Final approval

Skipping simulation increases trial cost.

Cost versus benefit view

Some buyers avoid simulation to save money.

In reality, one failed die costs far more than simulation work.

| Stage | Cost impact |

|---|---|

| Simulation | Low |

| Die rework | Medium |

| Die remake | High |

| Production scrap | Very high |

Practical example

In one complex hollow profile project, simulation revealed uneven flow near a thin rib.

After adjusting rib thickness slightly, the profile extruded smoothly on first trial.

Extrusion simulation software helps identify feasibility risks early.True

It predicts flow, stress, and temperature behavior.

Software simulation guarantees that an extrusion design will work perfectly in production.False

Simulation reduces risk but cannot eliminate all real-world variation.

Conclusion

Aluminum extrusion cross-section complexity has real limits defined by metal flow, tooling strength, and process control. Successful designs respect these limits, balance features carefully, and use simulation and experience together to turn complex ideas into stable production.