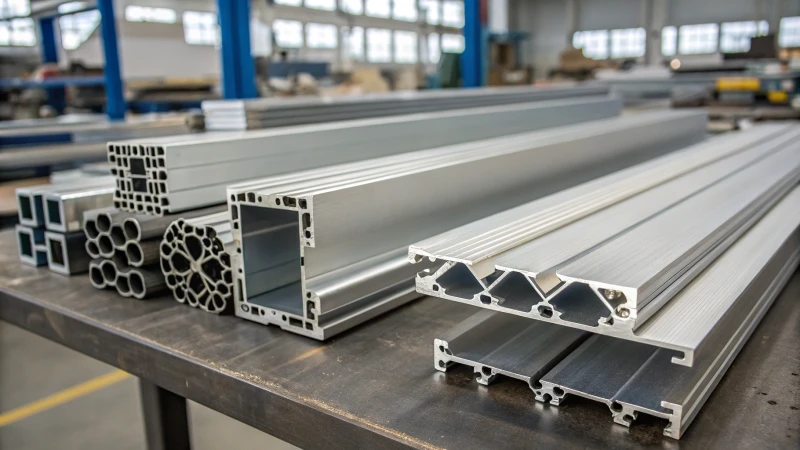

The Impact of Raw Material Quality on Finished Aluminium Profiles

The quality of raw materials is crucial in manufacturing aluminium profiles that are reliable and durable.

Raw material quality significantly impacts the performance, durability, and aesthetic appeal of finished aluminium profiles. High-quality alloys ensure mechanical strength, corrosion resistance, and efficient production processes, which are vital for sectors like construction and automotive.

While understanding the immediate impact on performance is essential, diving deeper into aspects such as alloy composition and impurity management offers valuable insights into maintaining high standards in aluminium production. Let’s explore these factors in detail.

High-quality alloys ensure corrosion resistance in aluminium.True

High-quality alloys enhance mechanical strength and corrosion resistance.

Impurity management has no effect on aluminium quality.False

Impurity management is crucial for maintaining high standards in production.

What Are the Key Mechanical Properties Affected by Raw Material Quality?

Understanding how raw material quality affects mechanical properties is crucial for manufacturing and engineering processes. This insight helps ensure product reliability, longevity, and performance.

Raw material quality impacts mechanical properties such as tensile strength, ductility, hardness, and fatigue resistance. Impurities or inconsistent composition can lead to defects and performance issues in the final product.

Tensile Strength and Ductility

The tensile strength of a material refers to its ability to withstand tension without breaking. High-quality raw materials are essential for achieving optimal tensile strength in the final product. For example, impurities in metals can create weak spots that reduce tensile strength and ductility, leading to premature failure under stress.

To ensure high tensile strength and ductility, manufacturers often use certified alloys with specific compositions. These alloys are designed to meet stringent performance standards, particularly in industries like aerospace and automotive. Material certification1 is critical for verifying the composition and purity of raw materials.

Hardness and Wear Resistance

Hardness measures a material’s resistance to deformation or indentation. It is a crucial property for applications requiring surface durability, such as cutting tools or machinery components. Raw material quality significantly influences hardness; impurities can result in uneven hardness distribution, affecting wear resistance.

Consistent quality in raw materials ensures uniform hardness, which is crucial for applications in manufacturing industries where precision is vital. Testing methods like the Brinell or Rockwell hardness tests can help identify material consistency issues.

| Material | Common Impurities | Impact on Hardness |

|---|---|---|

| Steel | Carbon, Sulfur | Reduces hardness consistency |

| Aluminium | Silicon, Iron | Causes soft spots |

Fatigue Resistance

Fatigue resistance is a material’s ability to withstand repeated stress cycles without failure. High-quality raw materials are necessary for maintaining fatigue resistance, especially in components subject to cyclic loads such as bridges or aircraft wings.

Inconsistencies in raw material quality can introduce micro-cracks or surface defects, reducing fatigue life. For this reason, materials used in high-stress environments are often subjected to rigorous fatigue testing2 to ensure their suitability.

Understanding these mechanical properties and their dependence on raw material quality enables manufacturers to select appropriate materials for their specific applications. This knowledge is essential for minimizing defects and enhancing product performance across various industries.

Impurities in metals reduce tensile strength.True

Impurities create weak spots, decreasing tensile strength and ductility.

Hardness is unaffected by raw material quality.False

Impurities cause uneven hardness, affecting wear resistance.

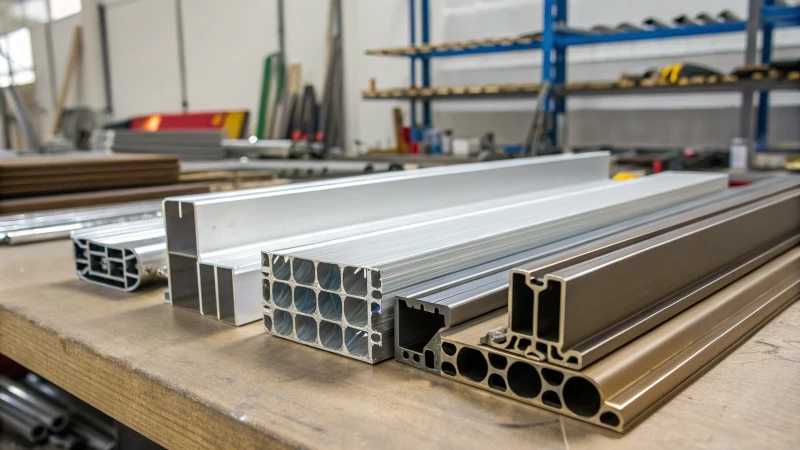

How Does Alloy Composition Influence Aluminium Profile Applications?

Aluminium alloys offer a versatile range of properties that make them ideal for various applications. But how does the specific composition of these alloys shape their suitability for different uses?

Alloy composition determines an aluminium profile’s mechanical properties, such as strength and corrosion resistance, thus influencing its application in industries like automotive, construction, and aerospace. Selecting the right alloy ensures optimal performance.

The Role of Alloying Elements

Different aluminium alloys contain varying elements like copper, magnesium, silicon, and zinc. These elements significantly alter the material’s properties. For example, aluminium alloy 60613 has magnesium and silicon, enhancing its strength and

corrosion resistance, making it suitable for structural applications.

Comparing Popular Aluminium Alloys

| Alloy | Main Elements | Common Applications |

|---|---|---|

| 6061 | Magnesium, Silicon | Structural frames, bridges |

| 6063 | Magnesium, Silicon | Architectural profiles, windows |

| 7075 | Zinc | Aerospace components |

The table above highlights how different compositions cater to specific needs. Alloy 7075, known for its high strength due to zinc, is ideal for the aerospace industry4, while 6063 is preferred for decorative applications.

Impact on Mechanical Properties

The mechanical properties of aluminium profiles are crucial for their applications. For instance, strength and ductility5 are vital in construction, where profiles need to withstand loads without deformation. High-strength alloys like 7075 offer excellent performance in such

demanding environments.

Considerations for Corrosion Resistance

Corrosion resistance is another critical factor influenced by alloy composition. Alloys with high silicon content, like 6063, exhibit excellent resistance to environmental factors. This makes them suitable for outdoor applications where exposure to elements is a concern.

Heat Treatment and Its Effects

Heat treatment can further modify an alloy’s properties. Solution heat treatment and aging processes enhance the strength of certain alloys, expanding their application range. For example, the T6 temper6 increases the hardness and strength of 6061, making it more

durable for structural use.

Understanding these aspects helps manufacturers and designers select the right alloy for specific projects, ensuring optimal performance and longevity.

Alloy 6061 is suitable for aerospace applications.False

Alloy 6061 is used for structural applications, not aerospace.

Alloy 7075 has high zinc content for strength.True

Zinc in 7075 provides high strength, ideal for aerospace use.

What Role Do Impurities Play in Aluminium Profile Manufacturing?

Understanding the role of impurities in aluminium manufacturing is crucial for ensuring product quality and performance. Let’s explore how these impurities affect aluminium profiles and why managing them is essential.

Impurities in aluminium can significantly impact the extrusion process and the final product’s quality. They affect mechanical properties, surface finish, and corrosion resistance, making impurity management vital for superior aluminium profiles.

Impact on Mechanical Properties

Impurities such as iron, silicon, and magnesium are common in raw aluminium. Their presence can alter the alloy’s mechanical properties, affecting strength7, ductility, and toughness. For example, excessive iron can lead to brittleness, compromising the profile’s structural integrity.

Surface Finish and Aesthetics

The presence of impurities can also degrade the surface finish of aluminium profiles. Impure alloys may result in surface defects, which affect anodizing or painting processes. This is crucial for industries prioritizing visual appeal8 and aesthetics, like architecture and design.

| Impurity | Effect on Surface Finish |

|---|---|

| Iron | Causes rough surfaces |

| Silicon | Leads to uneven coloring |

| Magnesium | Produces matte finish |

Corrosion Resistance

Corrosion resistance is another critical factor influenced by impurities. High-purity aluminium alloys are more resistant to corrosive elements. Impurities can form galvanic cells, accelerating corrosion rates. In outdoor applications, such as construction9 or marine environments, this can drastically reduce the product lifespan.

Efficiency of Extrusion Process

Impurities can hinder the extrusion process by causing clogs and uneven flow in the die channels. This not only slows down production but also increases energy consumption and wear on machinery. Consequently, maintaining low impurity levels enhances process efficiency and reduces costs10.

Traceability and Certification

Managing impurities involves ensuring traceability and certification of raw materials. High-quality suppliers provide certifications that guarantee minimal impurities, which is essential for compliance with industry standards and customer expectations11. Ensuring traceability helps in maintaining consistent quality across batches.

Iron impurities cause brittleness in aluminium.True

Excessive iron in aluminium can make it brittle, affecting integrity.

Silicon impurities improve surface finish of aluminium.False

Silicon leads to uneven coloring, degrading the surface finish.

How Important is Surface Finish for Aluminium Profiles?

The surface finish of aluminium profiles is more than just aesthetics. It affects durability, performance, and suitability for various applications, from construction to automotive industries. Understanding its significance is key to optimizing aluminium’s potential.

Surface finish on aluminium profiles influences corrosion resistance, visual appeal, and functionality. High-quality finishes enhance longevity and performance, making them crucial for applications in demanding environments like construction and automotive.

The Role of Surface Finish in Aluminium Profiles

Surface finish plays a critical role in the performance of aluminium profiles12, especially when these materials are used in outdoor or high-performance settings. A well-executed finish can significantly increase

corrosion resistance, which is essential for products exposed to moisture or salt. For instance, anodized finishes are popular for their ability to protect against oxidation while providing a sleek appearance.

Aesthetic Considerations

Beyond functional benefits, surface finish greatly impacts the visual appeal of aluminium products. A smooth, polished finish can enhance the aesthetic value13 of architectural structures, making them more desirable for high-end

projects. Finishes such as powder coating offer a variety of color choices and textures, enabling designers like David to align with specific design themes or brand requirements.

Impact on Durability and Maintenance

In terms of durability, surface finishes can reduce maintenance needs by minimizing the accumulation of dirt and simplifying cleaning processes. This is particularly beneficial in urban environments where pollution can tarnish surfaces. A well-selected finish not only extends the lifespan of the profile but also reduces long-term costs associated with maintenance.

| Finish Type | Advantages | Applications |

|---|---|---|

| Anodized | High corrosion resistance | Construction, Marine |

| Powder Coated | Color variety, UV protection | Automotive, Architecture |

| Brushed | Textured look, unique feel | Interior design, Accessories |

Surface Finish and Environmental Factors

Environmental considerations are increasingly vital in selecting surface finishes. Eco-friendly options such as low-VOC coatings14 are becoming popular as they align with sustainable manufacturing practices. The choice of finish can also impact the energy consumption of production processes and the recyclability of materials.

Customization and Innovation

Finally, innovation in finishing techniques allows for customization that meets specific industry requirements. For example, recent advancements in digital printing on aluminium enable bespoke designs that reflect a company’s unique identity or meet specific functional needs such as enhanced conductivity15 in electronic components.

By carefully considering the type and quality of surface finishes, businesses can ensure that their aluminium profiles meet both aesthetic and functional demands while supporting sustainability goals.

Anodized finishes protect aluminium from oxidation.True

Anodized finishes enhance aluminium's corrosion resistance, preventing oxidation.

Powder coating offers no color variety for aluminium.False

Powder coating provides a wide range of colors and textures for aluminium.

What Certifications Should You Look for in Aluminium Raw Materials?

Navigating the landscape of aluminium raw material certifications can be daunting. Knowing which certifications to prioritize ensures you source materials that are compliant, traceable, and of the highest quality. Discover the key certifications that can elevate your procurement process.

When sourcing aluminium raw materials, look for certifications like ISO 9001, ISO 14001, and EN 10204 3.1 or 3.2. These guarantee quality management, environmental standards, and traceability, ensuring materials meet industry specifications and regulatory compliance.

Understanding Key Aluminium Material Certifications

In the aluminium industry, certifications serve as a hallmark of quality, safety, and compliance. They provide assurance that the materials meet specific standards set by industry bodies and regulatory agencies. Let’s explore some essential certifications:

- ISO 9001: This certification focuses on quality management systems. Suppliers with ISO 9001 ensure consistent product quality and continuous improvement processes. This is crucial for buyers like David16 who prioritize reliability in their procurement.

- ISO 14001: Environmental management is a growing concern. This certification indicates a supplier’s commitment to sustainable practices. For environmentally conscious businesses, sourcing from ISO 14001 certified suppliers aligns with their values.

Exploring EN 10204 Certification Types

The EN 10204 standard specifies different types of inspection documents for metals. Two critical types for aluminium are:

- 3.1 Certification: Provides a statement of compliance with the order, including test results based on non-specific inspection and testing. This level is often sufficient for most construction needs17.

- 3.2 Certification: Offers more stringent requirements, including inspection by both the manufacturer and an external party. Industries like aerospace may require this for added assurance.

| Certification Type | Description | Application |

|---|---|---|

| 3.1 | Non-specific testing | General use |

| 3.2 | External inspection | Critical applications |

Importance of Traceability in Aluminium Supply Chain

Traceability is vital for quality control and regulatory compliance in aluminium procurement. Certifications like EN 10204 not only assure material properties but also facilitate traceability throughout the supply chain.

- Batch and Lot Tracking: Maintaining records of material batches helps in tracking any issues back to their source, reducing risk and ensuring accountability.

- Regulatory Compliance: Certifications ensure that materials meet international standards and regulations, essential for global trade.

For more insights on aluminium certification, exploring industry forums18 can be valuable.

Understanding these certifications empowers buyers to make informed decisions, ensuring that their aluminium raw materials meet both performance expectations and regulatory demands.

ISO 9001 certification ensures product quality.True

ISO 9001 focuses on quality management systems, ensuring consistent quality.

EN 10204 3.2 certification is for general use.False

EN 10204 3.2 involves external inspection, suited for critical applications.

Conclusion

Raw material quality is vital in aluminium profile manufacturing, affecting performance, durability, and aesthetics. High-quality alloys ensure mechanical strength and corrosion resistance for various applications.

-

Clicking this link provides insights into why material certification is essential for ensuring product quality and performance. ↩

-

Explore this link to understand various fatigue testing methods, which help ensure materials can withstand repeated stress. ↩

-

Learn about aluminium alloy 6061’s properties to understand why it’s chosen for structural applications. ↩

-

Discover the benefits of using aluminium alloy 7075 in aerospace for its high strength-to-weight ratio. ↩

-

Explore factors influencing strength and ductility to see how they determine an alloy’s suitability for construction. ↩

-

Understand T6 tempering to see how it enhances the properties of aluminium alloys like 6061. ↩

-

Understand how different impurities alter the strength and ductility of aluminium alloys. ↩

-

Learn how impurities lead to defects during anodizing, affecting the final aesthetic quality. ↩

-

Discover how impurity management enhances corrosion resistance in harsh environments. ↩

-

Explore how reducing impurities leads to cost-effective and efficient extrusion processes. ↩

-

Find out why certified materials are crucial for meeting industry standards and expectations. ↩

-

Explores the fundamental reasons why surface finish is crucial in various applications. ↩

-

Discusses how different finishes enhance the visual appeal of aluminium products. ↩

-

Provides insights into eco-friendly finishing options and their benefits. ↩

-

Covers recent advancements in finishing technologies for customized applications. ↩

-

Learn why ISO 9001 certification is a key indicator of a supplier’s commitment to quality management systems. ↩

-

Discover the differences between EN 10204 3.1 and 3.2 certifications and when each is applicable. ↩

-

Join discussions in industry forums to gain more insights on aluminium certifications and best practices. ↩